March 18, 2021 at 11:29 pm | Updated March 18, 2021 at 11:29 pm | 7 min read

The United Nations urges people to cut current food loss levels in half by 2030 to improve global food security and public health. The organization suggests connecting these reductions to climate change targets and using natural resources sustainably. To achieve these aims, they advise the use of innovative new approaches and technology. State-of-the-art sensors and accessible data analysis are becoming key solutions to solving food loss in both wealthy and developing countries, while benefiting stakeholders throughout the supply chain.

[Updated: March 2021]

Subscribe to the Felix instruments Weekly article series.

By submitting this form, you are consenting to receive marketing emails from: . You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact

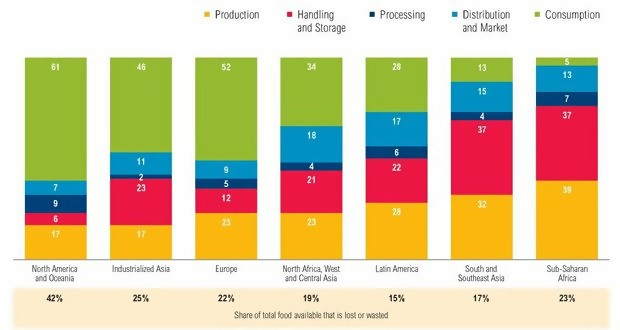

Figure 1: Food loss and waste, according to FAO. (Image credits: http://www.fao.org/platform-food-loss-waste/en/)

Food Loss vs. Food Waste

Food loss is the reduction in quantity and quality of food in the production and supply chain from producers to the market. Food waste, on the other hand, happens at the market and consumer level when food is not purchased, when it is thrown away before it reaches the table, or when it remains untouched in the consumer’s home (see Figure 1).

Impact on Climate Change

When food is lost or wasted, it does not just produce a financial impact, but also negatively affects other valuable resources such as land, water, and energy used to produce the food. Thus, given the noted loss statistics, it follows that one-third of pollution and resource consumption from this sector is wasted on lost commodities. Food waste alone is estimated to contribute 8% of global carbon emissions, and this doesn’t cover emissions due to food loss.

The UNEP has urged governments to include diet, along with food loss and waste, into climate action plans. The organization says this can reduce their food mitigation and adaptation contributions by up to 25 percent. This can also help countries improve food security and public health.

Figure 2: Food lost in various stages of supply change around the world. (Image credits https://sustainablefoodlab.org/initiatives/food-loss-and-waste/)

Where Does Food Loss Happen?

Food loss occurs in both developed and developing countries, though the amounts can differ, as shown in Figure 2.

Considering food loss during production, storage, and transportation stages, the range lies between 39% for wealthy countries and up to 87% for developing countries, according to recent reports from the FAO.

This is exponentially compounded, as 690 million suffered from hunger in 2019 and, in the same year, three billion people could not afford a healthy diet, according to a 2020 United Nations report. This situation has worsened due to the COVID-19 pandemic. Therefore, it is to the benefit of all of the stakeholders—farmers, handlers, processors, traders, and governments – to avoid harvest and post-harvest losses, and become part of the solution to produce enough food for a growing population.

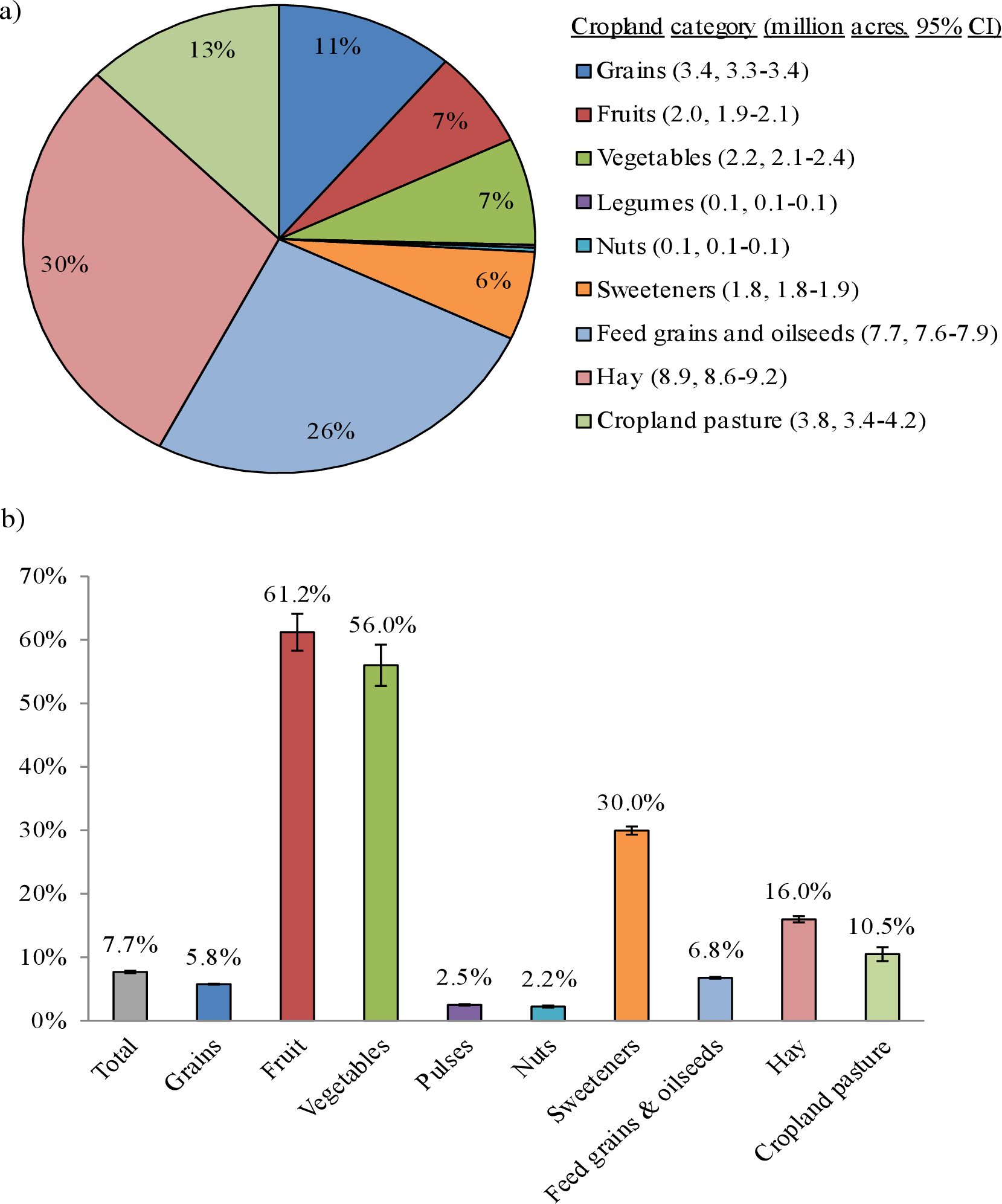

While being a more sustainable source of essential nutrients than meat, fresh produce also happens to be more prone to food loss and food waste. Overall, 56% of vegetables and 61% of fruits are wasted after harvest (see Figure 3). Fresh produce is lost at pre-harvest, harvest, and post-harvest stages for various reasons.

Tackling Food Loss Pre-Harvest

Pre-harvest causes of food loss can be due to environmental conditions and agricultural practices. There are well established practices for each crop that can minimize loss and improve yield, especially by using precision farming techniques and tools.

Food loss at the harvest and post-harvest stages has received less attention, and is thus an area that could see exponential returns if given proper resources.

Preventing Food Loss During Harvest

The two main contributors to loss of food during harvest are poorly selected harvest time and inadequate harvest methods. Several methods can be used in combination with precision farming to reduce harvest losses.

Harvest Time

Getting the time of harvest right is very important. Timing also impacts the post-harvest quality of fresh produce and storage. Produce should be harvested only when it is ready, so that it has the right appearance, taste, and quality, as immature produce can be inferior in desired attributes. However, it needs to be harvested early enough so that there is time to transport the fresh perishable produce to market. Technologies are stepping in to help with exactly this.

Produce quality meters, like those produced at Felix Instruments, are used by farmers and horticulturists to help decide if their crop is ready for harvest. Dry matter content, one of the many metrics used to judge fruit maturity, is not only a good indicator of harvest time, but also post-harvest quality and taste. However, many vegetables are ready before they reach maturity—okra being one example. In this case, parameters, such as skin color, size, and firmness are used to fix harvest time. The relevant parameter which growers should use will differ from crop to crop.

These small, handheld devices use state-of-the-art NIR (near-infrared) technology and accompanying software to identifying mature fruits. These WiFi-enabled devices are used not only to help predict harvest time, but also to monitor produce quality during transport and storage.

F-750 Produce Quality Meter can estimate dry matter, Total Soluble Solids (TSS or brix), titratable acidity, and external and internal colour. It is useful for a wide range of fruits and vegetables which are harvested at maturity, such as peppers, paprika, tomatoes, pumpkin, etc. The measurements are non-destructive and take only a few seconds, so many plants can be tested in a day.

F-751 Avocado Quality Meter, measures dry matter similar to the F-750 but is designed exclusively for avocados.

F-751 Mango Quality Meter, measures dry matter and Brix and is calibrated for many popular mango varieties.

F-751 Kiwi Quality Meter measures dry matter and Brix to establish maturity and ripeness.

All three quality meters integrate seamlessly with the new interactive application, Fruit Maps. Growers can use the app to load the data they collect on maturity and ripeness to add a spatial dimension to their data.

Harvest Methods

Harvest methods can influence the post-harvest quality of produce because of the possibility that fruits can get damaged. Mechanical injury through surface abrasions causing water loss, while bruising can trigger physiological damage through increased ethylene production that quickens the process of ripening and decay, affecting storage time and producing damaged fruits and vegetables.

Figure 3: a) The percent of harvested cropland wasted; b) Percent of the crop in each category wasted, Conrad et al. 2018 ( Image credits: https://doi.org/10.1371/journal.pone.0195405).

Minimizing Post-Harvest Food Loss

There is a 16-36% post-harvest loss of fruits every year due to mechanical, microbial, and physiological causes. There are various stages after harvest where things can go wrong, such as handling, storage, packing, or transportation.

- Handling: Processing involves washing, trimming, and packaging vegetables and fruits to clean them, remove diseased or damaged parts, and improve appearance.

- Grading: Fresh produce is sorted according to their shape, size, and colour into different grades. There is considerable loss of produce at this stage since many fruits and vegetables are rejected for being “ugly.” Government and supermarket policies, as well as consumer awareness, could end food loss at this stage.

- Packaging: Good protective packing material can prevent mechanical and physiological damage during transport and storage. Produce can then retain appearance, taste, and freshness.

- Storage and Ripening: Precooling can reduce up to 6% loss in weight during storage of both fruits and vegetables. Many climacteric fruits like apples are harvested before ripening, which happens during storage in ripening rooms. Temperature, humidity, and levels of oxygen(O2), carbon dioxide (CO2), and ethylene are closely monitored regularly to provide the best conditions to extend storage and for proper ripening.

Small handheld tools can be used in simple, as well as sophisticated, storage facilities to collect data on environmental conditions. By improving storage, quality of produce can be maintained and storage time extended. Both measures can go a long way in preventing food loss.

- F-920 Check It, measures relative humidity, CO2, and O2 from 0-100% in six seconds. It is used in storage facilities, ripening rooms, shipping containers, packaging lines, and retailers.

- F-940 Store It, measures and analyses ethylene, CO2, and O2 levels for optimal storage of produce.

- F-950 Three Gas Analyzer, monitors levels of ethylene, CO2, and O2. It can help producers and suppliers maintain optimal conditions at every phase of the supply chain to guarantee high produce quality.

- F-960 Ripen It! Gas Analyzer, analyses the levels of ethylene, CO2, and O2 simultaneously within 30 seconds for quick decision making during the ripening process.

- The F-750 and F-751 are useful in monitoring quality at critical points to sort fresh produce according to ripeness.

Use in Research

Many of these tools have been used for more than a decade in developed countries like the USA, Europe, and Australia. Today, there is a drive to introduce these tools to developing countries, as well. For example, as part of a study by the International Potato Centre (CIP) of the CGIAR, Felix tools, which can detect low quantities of ethylene, were used in research to suggest low-cost techniques to extend the shelf life of important tuber crops during postharvest storage in Ghana. Trials of these kind fit with UN and FAO recommendations to increase the use of technology and try new approaches.

Solutions

Technology can help in various stages of the supply chain. It is notable that developed countries have less food loss through the use of precision instruments, which can be used in the supply chain to collect information on produce and monitor them. Technology alone cannot, however, solve all the problems of food loss in post-harvest stages. Government action is needed to fix infrastructure. Supermarkets can help by relaxing their stringent specification on the appearance of the produce. Better adoption in developing countries should also be promoted by international organisations. By preventing food loss and waste, we can protect resources and the environment by reducing the demand for food production inthe first place.

—

Vijayalaxmi Kinhal

Science Writer, CID Bio-Science

Ph.D. Ecology and Environmental Science, B.Sc Agriculture

Sources

Conrad, Z, Niles M.T, Neher, D.A, Roy, E.D, Tichenor, N.E, & Jahns, L. (2018) Relationship between food waste, diet quality, and environmental sustainability. PLoS ONE 13(4): e0195405. https://doi.org/10.1371/journal.pone.0195405

FAO. Technical Platform on the Measurement and Reduction of Food Loss and Waste. Retrieved from http://www.fao.org/platform-food-loss-waste/food-loss/definition/en/

FAO. Food Loss and Food Waste. Retrieved from http://www.fao.org/food-loss-and-food-waste/en/

FAO. (1989).Prevention of post-harvest food losses fruits, vegetables and root crops a training manual. Retrieved from http://www.fao.org/3/T0073E/T0073E01.htm

Gabbatiss, J. (2018, February 21). Fruit and vegetable waste from farms ‘could feed population of Birmingham or Manchester for a year’, says environmental charity. Retrieved from

https://www.independent.co.uk/environment/fruit-vegetables-food-waste-farms-uk-birmingham-manchester-feedback-a8220171.html

Maiti, R., Thakur, A.K., Gupta, A. l & Debashis, M. (2018). Post harvest management of agricultural produce. In book: Research Trends in Bioresource Management and Technology, Publisher: American Academic Press, USA, pp.137-166. Retrieved fromhttps://www.researchgate.net/publication/330845976_POST_HARVEST_MANAGEMENT_OF_AGRICULTURAL_PRODUCE

Ramjan, M., & Ansari, M.T. (2018). Factors affecting of fruits, vegetables and its

Quality. Journal of Medicinal Plants Studies 2018; 6(6): 16-18. Retrieved from http://www.plantsjournal.com/archives/2018/vol6issue6/PartA/6-5-15-686.pdf

Yahaya, S.M., & Mardiyya, A.Y. (2019). Review of Post-Harvest Losses of Fruits and Vegetables. Biomedical Journal of Scientific & Technical Research.DOI: 10.26717/BJSTR.2019.13.002448.

https://biomedres.us/pdfs/BJSTR.MS.ID.002448.pdf

Related Products

- F-751 Grape Quality Meter

- Custom Model Building

- F-910 AccuStore

- F-751 Melon Quality Meter

- F-751 Kiwifruit Quality Meter

- F-750 Produce Quality Meter

- F-751 Avocado Quality Meter

- F-751 Mango Quality Meter

- F-900 Portable Ethylene Analyzer

- F-950 Three Gas Analyzer

- F-920 Check It! Gas Analyzer

- F-960 Ripen It! Gas Analyzer

- F-940 Store It! Gas Analyzer

Most Popular Articles

- Spectrophotometry in 2023

- The Importance of Food Quality Testing

- NIR Applications in Agriculture – Everything…

- The 5 Most Important Parameters in Produce Quality Control

- Melon Fruit: Quality, Production & Physiology

- Fruit Respiration Impact on Fruit Quality

- Guide to Fresh Fruit Quality Control

- Liquid Spectrophotometry & Food Industry Applications

- Ethylene (C2H4) – Ripening, Crops & Agriculture

- Active Packaging: What it is and why it’s important