November 26, 2019 at 1:38 am | Updated November 26, 2019 at 1:38 am | 7 min read

The rate of post-harvest respiration is one of the primary physiological processes monitored during storage, transport, handling, sorting, and sales to ensure the quality of fresh produce and to cut losses. Measuring levels of oxygen is one of the methods used to assess respiration. There are many methods of gas analysis that are used in both research and practice to plan and maintain the optimal post-harvest atmosphere.

Importance of Oxygen in Post-Harvest Operations

To ensure the quality of stored fruits and vegetables post-harvest and to extend storage time, levels of the following three gases are important: oxygen, carbon dioxide, and ethylene. Though they are all connected, the role of each of these gases in fruit physiology is different and determines what levels of each should be maintained in post-harvest.

Controlling Respiration

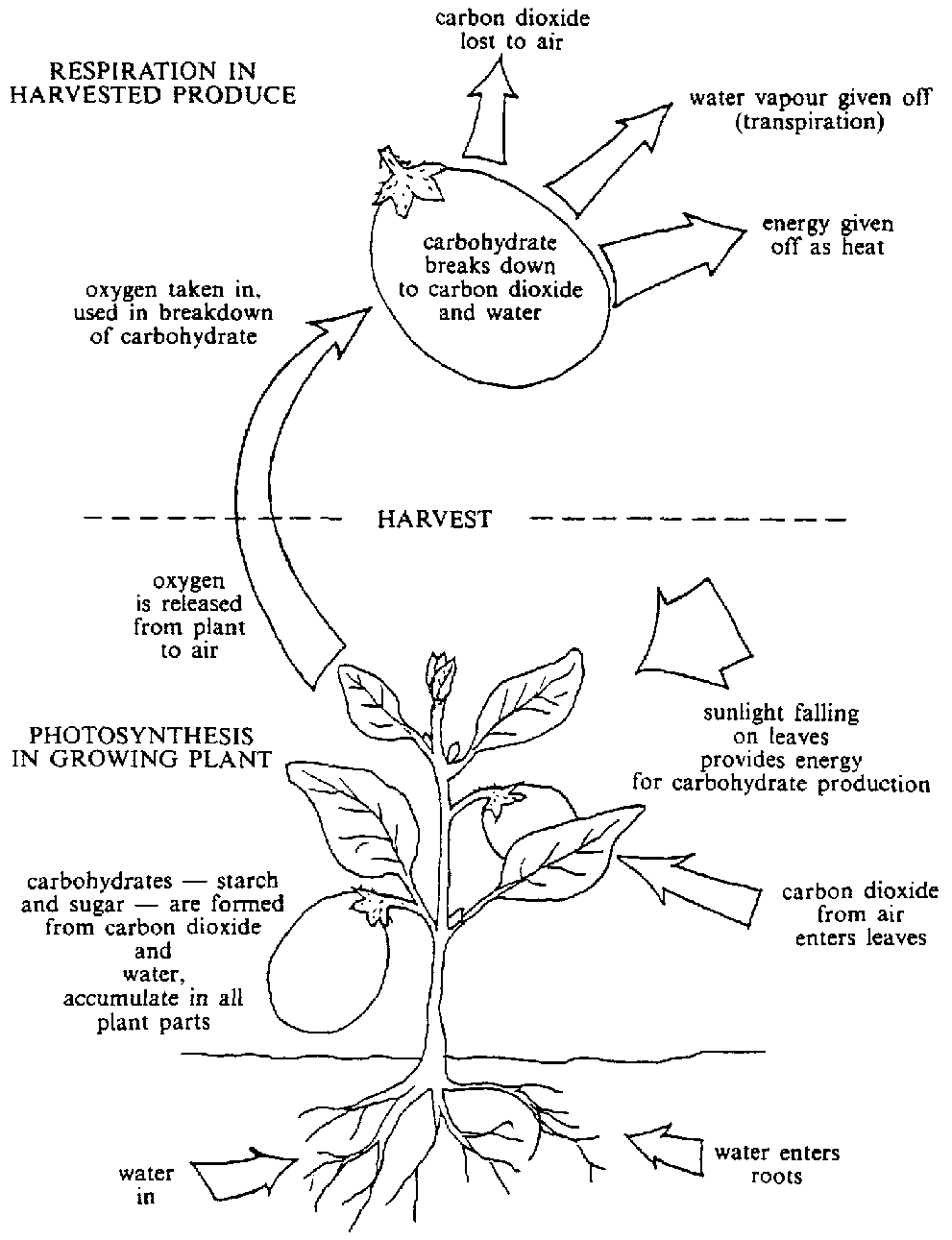

Figure 1: (Image credits: FAO, http://www.fao.org/3/T0073E/T0073E06.GIF)

Subscribe to the Felix instruments Weekly article series.

By submitting this form, you are consenting to receive marketing emails from: . You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact

Respiration in fruit continues even after they are harvested. Respiration, or breathing, is the process by which living things take in oxygen to breakdown carbohydrates. As shown in the equation below, carbon dioxide is one of the end products, along with water vapor and heat, as shown in the equation below:

Carbohydrates + O2 ► CO2 + H2O + Energy

When respiration occurs in harvested produce, it uses stored starch and sugar which leads to aging, shrivelling, and decay of produce. Before harvest, respiration losses to fruit mass are offset by photosynthesis in leaves, which keeps manufacturing new food and adds starch and sugar (See Figure 1).

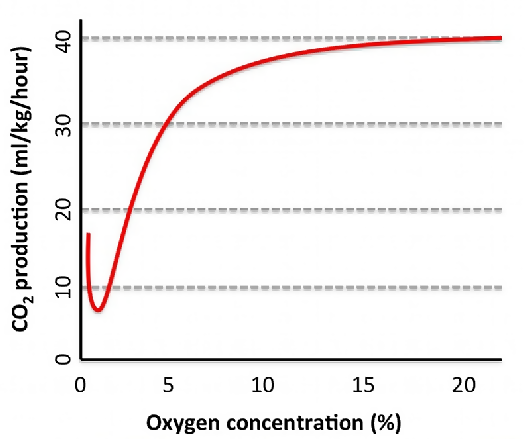

The normal concentration of oxygen in the air is twenty percent, and when oxygen concentration decreases, it reduces the rate of respiration. This principle is used to reduce oxygen during storage of vegetables and fruits to decrease respiration and thereby extend storage time.

It has been established that the respiration rate decreases only when the level of oxygen falls below five percent.

It is not advisable to decrease oxygen content completely. In the absence of oxygen, anaerobic respiration begins in the fruit, which results in fermentation. Sugar changes to alcohol and carbon dioxide which produces unpleasant flavors and alters the texture, affecting the quality of fruit. Anaerobic respiration uses stored sugar and starch much faster than normal respiration and, therefore, causes premature aging of produce. In the end, this reduces storage time more than normal respiration.

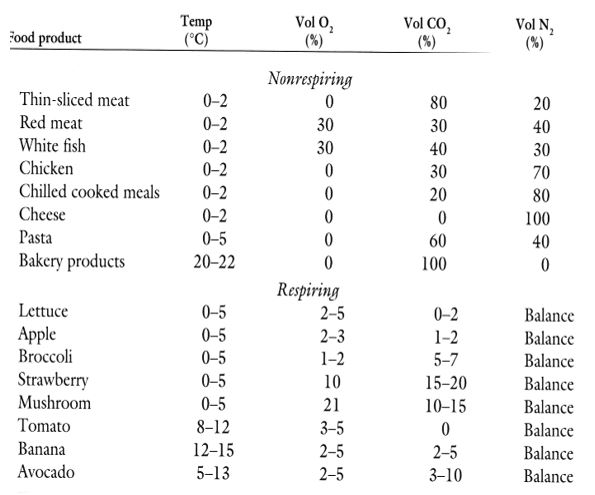

The anaerobic compensation point (ACP) is the point when oxygen uptake and carbon dioxide production is at a minimum. To prevent fermentation, oxygen levels should be maintained above this level. See Table 1 for recommendations on general storage atmospheric conditions.

Figure 2: Respiration levels fall when oxygen concentrations drop below 5% in the atmosphere. (Image credits: https://www.postharvest.net.au/postharvest-fundamentals/atmosphere/oxygen-and-carbon-dioxide/)

Post-harvest fresh fruit and vegetable respiration can be affected by temperature, gas composition, wounding, and pest attacks. The variety of fruit will also influence how long it can be stored and under which conditions.

Therefore, it is important to measure the level of oxygen precisely to be able to maintain the perfect medium between too much or too little oxygen.

Table 1: “Recommended storage conditions for some non-respiring and respiring food products (Lioutas, 1988).” (Image credits: DOI: 10.21273/HORTTECH.2.3.303).

High Oxygen Modified Atmosphere Preservation of Fresh Produce

One mode of modified atmosphere packaging (MAP) is artificially maintaining low levels of oxygen. On the contrary, another kind of MAP currently being tried involves using high levels of oxygen.

Since the mid-1990s, research has been exploring the possibilities of using high levels of oxygen (up to eighty to ninety percent of the atmosphere) in packaging to preserve vegetables. There are many reasons this method is gaining interest; some of them are as follows:

- When fruits and vegetables are treated with high oxygen, there is a reduction of respiration and ethylene production. This slows browning and improves the preservation of produce.

- This kind of packaging can avoid the use of chemicals to preserve perishable produce.

- It is an alternative to the high carbon dioxide and low oxygen method, as that can produce off-flavors and color due to fermentation.

- High oxygen conditions in combination with carbon dioxide are toxic or inhibit the growth of decay causing microbes such as Pseudomonas fragi, Aeromonas hydrophila, Yersinia enterocolitica, Listeria monocytogenes, Salmonella typhimurium, S. enteritidis, Botrytis cinerea, and Penicillium digitatum.

- Fruits do not suffer any damage in appearance or quality due to high oxygen. That is, too much oxygen is not toxic to vegetables and fruits.

Atmospheres with eighty percent oxygen, with or without carbon dioxide, have been established as good for vegetables and fruits.

High oxygen packaging is also being investigated for packaging of non-respiring food, such as poultry products, instead of high carbon dioxide and nitrogen, to control food spoilage due to the growth of bacteria and fungus.

Control systems are being developed that can regulate not only oxygen but also other important gases, as well as temperature and humidity. Here, precise tools for research and later in practice are important.

Modern Techniques to Detect Respiration

The most common methods used to control respiration rates by measuring oxygen are gas chromatography, electrochemical and infrared gas analyzers, wireless sensor networks, and portable gas analyzers.

- Gas Chromatography: Gas samples are taken from the inlet and outlet of a gas chamber containing fruit pieces. The collected gas is then injected into a gas chromatograph that consists of columns filled with nitrogen gas that separates the components in the gas mixture. Peaks of the component gases are measured by flame ionization and thermal conductivity detectors at 1500c and are depicted in charts. The peaks are then analyzed with software. The gas chromatograph is a complicated instrument that requires specialized personnel to operate.

- Wireless Sensor Networks (WSN): A study tried out the WSN to see how efficient they were to monitor respiration. The sensors were able to record oxygen levels and temperatures in climate chambers with the fresh produce and send the signals to the receiver outside. However, they lacked sensitivity to low oxygen levels and cannot measure carbon dioxide.

- Infrared Gas Analysis: The infrared gas analysis system uses 24 storage containers and a sampling sequence along with the portable infrared gas analyzer. It can record levels of carbon dioxide and oxygen with the same accuracy as traditional gas chromatography. It requires very little sample preparation and is faster than gas chromatography.

- Portable Gas Analyzers: These allow for non-destructive, rapid measurements without any sample preparations. They are ideal for headspace and continuous gas measurements to give precise readings.

Portable Gas Analyzers

In contrast to portable gas analyzers, the other methods require large equipment, varying degrees of sample preparations, and lengthy procedures. While they may be available in research laboratories, they are expensive and require expertise to operate.

Felix Instruments produces many portable gas analyzers that avoid these problems. Their devices measure oxygen electrochemically, from zero to one hundred percent. Besides room atmospheres, they can be used to measure air within pacakaging. An accessory thin metal probe pierces packaging to read gas content.

The readings are available within seconds, and they have a data logger that stores data with date and time. They have WiFi and Bluetooth for quick data transfer.

- The F-901 AccuStore & AccuRipe are controllers that are fixed in a room/space to monitor and control oxygen, carbon dioxide, and ethylene in monitored storage spaces. By controlling and regulating levels of the gas, the controllers maintain the optimum atmospheric conditions required to extend storage time and help in proper ripening of fruits.

- The F-920 Check It! is a handheld device that is suitable for air measurements and for MAPs. It is useful anywhere in the supply chain from the laboratory, transport, storage, shipping, export/ import control, to retail sectors.

- The F-940 Store It! Gas Analyzer is also a light and portable device that can be used in storage and in retail shops to increase shelf-life by monitoring the levels of gases, oxygen, and carbon dioxide. It is easy and user-friendly.

- The F-950 Three Gas Analyzer can electrochemically record gas levels of oxygen, carbon dioxide, and ethylene. It is small and light for use anywhere in the supply chain for a wide range of fruits and vegetables, including those in MAPs.

- The F-960 Ripen It! Gas Analyzer measures oxygen, carbon dioxide, and ethylene together so that people can get a quick estimate of conditions in ripening rooms. It is a small and portable device that can be used within the ripening rooms or operated from the outside through connections to the internal atmospheres.

Advantages of Portable Devices

The portable devices that Felix Instruments have produced are simple enough for use at any point in the supply chain, with little or no training. Accurate readings are given in real time. These qualities are increasing their use not just in the supply chain, but also in research. Scientists and innovators are constantly working to improve packaging and storage conditions to decrease fresh produce loss. Felix devices are, thus, aiding research and practical operations in the food industry to improve food delivery.

—

Vijayalaxmi Kinhal

Science Writer, CID Bio-Science

Ph.D. Ecology and Environmental Science, B.Sc Agriculture

Sources

Annette Wszelaki, A., Yehoshua, S. B., & Mitcham, B. (1999). Do High Oxygen Atmospheres Control Postharvest Decay of Fruits and Vegetables. Perishables Handling Quarterly Issue, 99:22-25. Retrieved from http://ucce.ucdavis.edu/files/datastore/234-74.pdf

FAO. 4.7 Respiration. Retrieved from http://www.fao.org/3/T0073E/T0073E02.htm

Mohamed, F., Landry, J. & Raghavan, V. (2003). Development and testing of an automated infrared gas analysis system for postharvest respiration study. Applied Engineering in Agriculture. 19. doi: 10.13031/2013.13656.

Leon, G. & Herman, P. (1992). Modified Atmosphere and Vacuum Packaging to Extend the Shelf Life of Respiring Food Products. HortTechnology. 2. DOI: 10.21273/HORTTECH.2.3.303

Liu, Z., Yan, C., Wang, X., & Han, X. (2011). Design for Real-Time Monitoring System of High Oxygen Modified Atmosphere Box of Vegetable and Fruit for Preservation. In D. Li, Y. Liu, and Y. Chen (Eds.): CCTA 2010, Part I, IFIP AICT 344:472–475. Retrieved from https://link.springer.com/content/pdf/10.1007/978-3-642-18333-1_55.pdf

Løkke, M.M., Seefeldt, H.F., Edwards, G., & Green, O. (2011). Novel Wireless Sensor System for Monitoring Oxygen, Temperature and Respiration Rate of Horticultural Crops

Post Harvest. Sensors, 11:8456-8468; doi:10.3390/s110908456

Postharvest Management of Vegetables. Oxygen and carbon dioxide. Retrieved from https://www.postharvest.net.au/postharvest-fundamentals/atmosphere/oxygen-and-carbon-dioxide/

Rossaint, S., Klausmann, S., Kreyenschmidt, J. (2015). Effect of high-oxygen and oxygen-free modified atmosphere packaging on the spoilage process of poultry breast fillets, Poultry Science, 94:93–103. doi: https://doi.org/10.3382/ps/peu001

Thewesa, F. R., Botha, V., Brackmann, A., Weber, A., & Anesea, R. O. (2015). Dynamic controlled atmosphere and ultralow oxygen storage on ‘Gala’ mutants quality maintenance. Food Chemistry, 188: 62-70. doi:https://doi.org/10.1016/j.foodchem.2015.04.128

Woodford, C. (2019, Sept 14). Chromatography. Retrieved from https://www.explainthatstuff.com/chromatography.html

(Image credits: FAO, http://www.fao.org/3/T0073E/T0073E06.GIF)

Related Products

- F-751 Grape Quality Meter

- Custom Model Building

- F-901 AccuRipe & AccuStore

- F-751 Melon Quality Meter

- F-751 Kiwifruit Quality Meter

- F-750 Produce Quality Meter

- F-751 Avocado Quality Meter

- F-751 Mango Quality Meter

- F-900 Portable Ethylene Analyzer

- F-950 Three Gas Analyzer

- F-920 Check It! Gas Analyzer

- F-960 Ripen It! Gas Analyzer

- F-940 Store It! Gas Analyzer

Most Popular Articles

- Spectrophotometry in 2023

- The Importance of Food Quality Testing

- NIR Applications in Agriculture – Everything…

- The 5 Most Important Parameters in Produce Quality Control

- Melon Fruit: Quality, Production & Physiology

- Guide to Fresh Fruit Quality Control

- Liquid Spectrophotometry & Food Industry Applications

- Ethylene (C2H4) – Ripening, Crops & Agriculture

- Fruit Respiration Impact on Fruit Quality

- Active Packaging: What it is and why it’s important