October 14, 2021 at 10:24 pm | Updated April 11, 2022 at 6:44 am | 6 min read

Degreening of postharvest citrus allows growers, suppliers, and distributors more flexibility to react to market demands. However, for a long time, there was no clarity on the costs of degreening. Not being able to anticipate total production costs is a major obstacle for any grower. So, a team of multidisciplinary scientists decided to track the color changes and associated costs during artificial degreening in ethylene chambers.

Why Postharvest Citrus are Degreened

Unlike most fruits, the color of the citrus fruit skin does not correspond with internal ripeness, but more with the climatic conditions. Lemons are often picked when they have a minimum of 20% juice and reach 58 mm diameter. The fruits are mature but still green at this stage. Leaving fruit on the tree, growers would have to wait up to two months longer before the desired consumer color is achieved. This can reduce time available for transport, increase the likelihood of bruising, and cut profits.

Hence, citrus is harvested early, while it is still green, and degreened artificially. When left on trees to ripen naturally, lemons typically turn yellow—and grapefruits reddish-yellow—by the end of October or mid-November.

Subscribe to the Felix instruments Weekly article series.

By submitting this form, you are consenting to receive marketing emails from: . You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact

In Spain, 40% of the lemons (Citrus macrophylla) are mature enough for harvest by mid-September. Fruits harvested at this time, the beginning of the season, must be artificially degreened. In contrast, fruits harvested later in the season are already developing their characteristic colors, and need little help achieving consumer-desired traits.

Degreening Advantages and Disadvantages

During degreening, ethylene gas is used to break down chlorophyll and encourage the synthesis of carotenoids, which make the peels yellow and orange.

However, ethylene, a phytohormone, triggers many other ripening processes besides a change in color. Changes in texture, flavor, and taste are common. The rate of alterations will depend on environmental conditions such as temperature, relative humidity, and concentrations of CO2 and O2. Some of the changes that occur due to ethylene are an increase in respiration and senescence, which can lower fruit quality.

In citrus fruits, degreening impacts quality by increasing the susceptibility of fruits to stem end rot. The calyx and rind can also senesce faster, and the fruit can suffer weight loss. However, the benefits of degreening outweigh its disadvantages, so the practice continues.

Surprisingly, the costs of degreening are seldom included in market analysis. Thus, the financial benefits of degreening postharvest citrus are not clear.

Quantifying Benefits of Degreening Postharvest Citrus

To shed more light on the costs and underlying biological reasons of degreening, a team of Spanish scientists from different backgrounds such as agriculture, horticulture, microbiology, and economics came together to analyze the process of degreening lemon and grapefruit.

The multi-disciplinary team of Conesa, Brotons, Manerac, and Porras examined the changes to rind color, the rate of change, the duration of treatment necessary, and the costs involved based on harvesting dates. The scientists also tested the natural degreening of fruits on trees to compare it with the rind color changes that took place in the ethylene chamber.

The following varieties were used in the experiment:

- ‘Eureka’, ‘Lisbon’ and ‘Fino 49’ in lemon

- ‘Marsh’, ‘Red blush’, ‘Rio Red’ and ‘Star Ruby’ in grapefruit

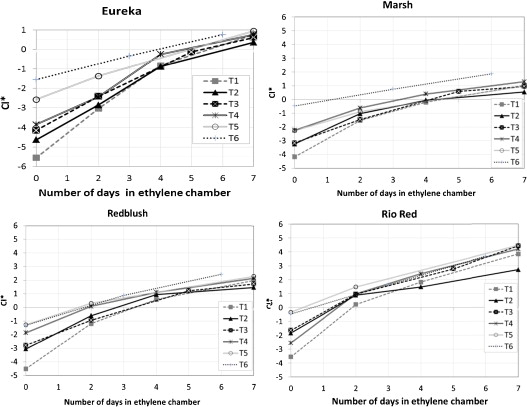

Figure 1: “CI* values in Eureka lemon and grapefruit varieties Marsh, Redblush and Rio Red from harvest (day 0) to the seventh day in the ethylene chamber for the six weekly

lots (T1–T6) in 2012,” Conesa et al 2014. (Image credits: https://doi.org/10.1016/j.scienta.2014.09.026)

Four trees of each variety were selected from healthy groves. Ten fruits were randomly collected from each variety over six weeks. The scientist measured the fruit skin color in the field and then placed them in ethylene chambers. For six days, fruits were exposed to a continuous flow of 94.5% N2 and 5.5% C2H4 to keep ethylene levels at 5 ppm. The temperature was maintained at 22–25oC and the relative humidity at 90–95%. Air circulation was used to keep CO2 levels below 1% during degreening. During this time, continuous CO2 and ethylene measurements were necessary.

There are gas analyzers on the market that are specifically made for regulating the atmosphere during degreening, such as the F-901D10 and F-901D200 AccuRipe, which are part of the F-901 AccuStore & AccuRipe – Precision Atmosphere Control series. These tools not only take CO2 and ethylene measurements, but also have a controller to regulate the flow of ethylene for degreening. Others, such as the portable gas analyzer F-960 Ripen It!, manufactured by Felix Instruments Applied Food Science, can assist in this process by providing rapid, on site CO2 and ethylene measurements.

Rind color was measured twice during the degreening process and subsequently when the process was deemed complete—when lemons were yellow and grapefruits reddish-yellow. This process was repeated six times in the years 2012 and 2013. A spectrophotometer was used to measure the rind color and calculate the color index (CI*).

Degreening Costs on Cultivars and Harvest Date

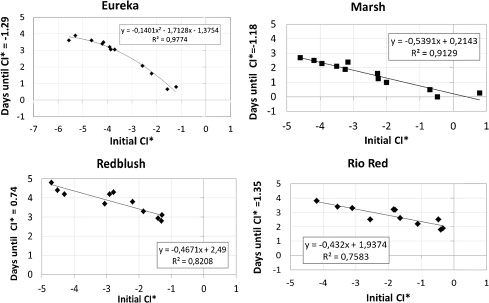

Figure 2: “Relation between number of days necessary to reach commercial CI* values and CI* at harvest in Eureka and the grapefruit varieties Marsh, Redblush and Rio Red in

2012. Their behavior in 2013 was similar,” Conesa et al 2014. (Image credits: https://doi.org/10.1016/j.scienta.2014.09.026)

There was no significant variation in color change patterns between the three cultivars considered for lemon: ‘Eureka’, ‘Lisbon’ and ‘Fino 49’; so the scientists used results of only Eureka to represent all three lemon varieties. There was, however, a difference between the varieties of grapefruits.

All the lemon varieties showed a similar pattern of degreening on the trees. In grapefruits, ‘Rio Red’ started greener than ‘Star Ruby’, and thus required a longer time to develop the characteristic color. It was only in mid-January that ‘Rio Red’ fruits reached the final color of ‘Star Ruby.’

The scientists found some clear patterns in the artificial degreening process:

- The initial color index of citrus increased with harvest dates. As the season proceeded, the lemons were less green. The degreening process was the fastest in all citrus—both lemons and grapefruits—that were initially greener; see Figure 1.

- However, the higher the initial color index was, the less days were needed to achieve commercially viable color; see Figure 2. With this result, the scientists were able to find a way people could accurately anticipate degreening time and associated costs.

- The experiment also showed that artificial degreening significantly decreased the number of days needed for fruits to achieve commercially-viable color. While the process takes months on trees, the fruits in the ethylene chamber needed only a maximum of five days, depending on harvest date, to achieve the same result.

Calculating Degreening Costs

Artificial degreening did account for a substantial part of the production costs. Using the data from the experiment, the scientists showed that it was possible to make three important predictions with a high degree of accuracy:

- Predict color index of fruits on any given date, based on the color index at harvest, using the natural degreening data.

- Estimate the number of days needed in the ethylene chamber, for fruits of a given color index, using the artificial degreening data.

- Calculate degreening costs, depending on the color index at harvest.

To calculate the degreening costs, the scientists considered the following expenses:

- Energy at the rate of 22€ /t

- Acetyl at 7€ /t

- Fruit losses at 51€ /t

The total costs were 80€ /t for five days or 16 € /t for each day.

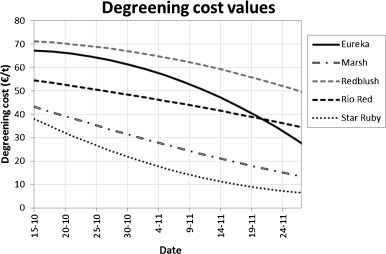

Figure 3: “ Degreening costs for Eureka, Marsh, Redblush, Rio Red, and Star Ruby, estimated for seasons 2012 and 2013,” Conesa et al 2014. (Image credits: https://doi.org/10.1016/j.scienta.2014.09.026)

In the experiment, the daily costs of degreening were 16 € per ton of fruit. Since the scientists were able to calculate the number of days to reach commercial color in prediction 2, they could calculate total costs for each variety.

The scientists found that the degreening of Eureka and other lemons formed a major portion of their total production costs. The degreening expenses, which represent 50% of costs for early harvests, decrease as the season proceeds.

For grapefruit, the degreening costs also depended on the variety, as shown in Figure 3. Degreening costs for ‘Star Ruby’ and ‘Marsh’ were half of the costs for ‘Red Blush’ and ‘Rio Red.’ From mid-season onwards, the degreening costs reduced by 50% for ‘Star Ruby’ and ‘Marsh,’ but only by 8% for ‘Red Blush’ and ‘Rio Red.’

Answering Industry Needs

This study was simple, yet it provided several much-needed insights for the citrus industry. The scientists found linear relationships that could predict the duration during natural, as well as artificial, degreening processes. Since growers can now predict the time and costs of artificial degreening, the growers can choose the optimum date to harvest their fruits, based on expected market prices. These last-minute decisions can increase growers’ income, as degreening accounts for a major portion of their production costs.

—

Vijayalaxmi Kinhal

Science Writer, CID Bio-Science

Ph.D. Ecology and Environmental Science, B.Sc Agriculture

Sources

Conesa, A., Brotons, J. M., Manera, F. J., & Porras, I. (2014). The degreening of lemon and grapefruit in ethylene atmosphere: A cost analysis. Scientia Horticulturae, 179, 140–145. https://doi.org/10.1016/j.scienta.2014.09.026

Related Products

- F-901 AccuRipe & AccuStore

- F-751 Melon Quality Meter

- F-751 Kiwifruit Quality Meter

- F-750 Produce Quality Meter

- F-751 Avocado Quality Meter

- F-751 Mango Quality Meter

- F-900 Portable Ethylene Analyzer

- F-950 Three Gas Analyzer

- F-920 Check It! Gas Analyzer

- F-960 Ripen It! Gas Analyzer

- F-940 Store It! Gas Analyzer

Most Popular Articles

- Spectrophotometry in 2023

- The Importance of Food Quality Testing

- NIR Applications in Agriculture – Everything…

- The 5 Most Important Parameters in Produce Quality Control

- Melon Fruit: Quality, Production & Physiology

- Liquid Spectrophotometry & Food Industry Applications

- Ethylene (C2H4) – Ripening, Crops & Agriculture

- Guide to Fresh Fruit Quality Control

- Active Packaging: What it is and why it’s important

- Understanding Chemometrics for NIR Spectroscopy