October 21, 2020 at 9:25 pm | Updated October 21, 2020 at 9:25 pm | 7 min read

Food security and the quality of products are two vital aspects that concern not only producers, but also planners and governments. Nearly half of the fresh produce is lost, but much of this loss can be prevented by using technological solutions that have been tried and tested. A new wave of innovations has miniaturized techniques, making them easy to use and far more affordable than large instruments. Devices for analyzing can have a significant impact on the food industry.

Fresh Produce Storage

Proper food storage is essential for maintaining the quality and safety of both fresh and packaged products during supply and distribution. There are also many socio-economic reasons to improve storage.

Food quality: There are many ways in which storage can influence quality:

Subscribe to the Felix instruments Weekly article series.

By submitting this form, you are consenting to receive marketing emails from: . You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact

- Storage has to be designed so that fresh produce at retail has an excellent appearance, texture, and flavor to meet consumer satisfaction.

- Quality also includes the nutritional value of fresh produce.

- Cold storage or modified atmosphere packaging aims to reduce micro-organism growth in food and prevent spoilage and poisoning.

Distribution: Food has to be stored in many places from the time it is harvested to the time it reaches retailers. This includes the transportation of food, whether it is fresh, packaged, or processed.

Food security: Storing food extends the season when a fruit or vegetable is available. Storage, therefore, can provide a better diet year-round. Fresh produce these days are also exported to reach far-flung countries to meet a demand for exotic food.

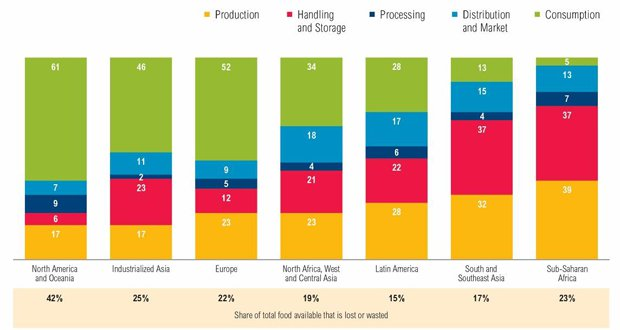

Figure 1: More food is lost in earlier stages of the supply chain in developing countries and during the later stages in medium and developed countries. (Image credits https://sustainablefoodlab.org/initiatives/food-loss-and-waste/)

Market conditions: It makes economic sense to store excess production during the peak season when prices for fresh produce are low. By selling them later, producers and suppliers can command better prices for their products.

Avoid food waste: According to FAO, forty-five percent of fresh vegetables, fruits, roots, and tubers are lost, making them the most wasted food items. In developing countries, about 40% of food waste happens during post-harvest and before it reaches retailers. This is a result of inadequate or wrong storage and transport conditions due to a lack of proper technical and management solutions.

Storage Conditions

The following factors have to be considered to ensure the correct and efficient storage of fresh produce:

Condition of food at harvest

- Type of fresh produce

- Type of containers

- Temperature of storage

- Humidity of storage

- Gaseous levels in storage rooms

With the proper use of technology, food loss in both developing and developed countries can be prevented or reduced to ensure that food is stored in the right conditions. Some of the approaches that can be adopted are discussed below. We also show how devices for analysis can play an essential role in these methods.

Harvest Quality

It is crucial to pick fruits and vegetables at the correct time. They have to be fully mature so that they can ripen adequately later. If they are harvested too early, the final taste and appearance of the fruit will not be ideal. A later harvest lets the fruits develop the desirable attributes, but it cuts short the time climacteric fruits can be stored. Non-climacteric fruits have to be picked just before full ripening, as they can’t ripen post-harvest.

There are small portable instruments available that measure the amount of dry matter and Brix, which allows farmers to estimate the optimal harvest time.

Felix Instruments produces some quality meters using Near Infrared (NIR) spectroscopy to measure dry matter, Brix, and titrable acidity, as well as the external and internal color of fruits. The measurements are non-destructive and rapid, so several plants and fruits can be tested in a day.

- F-750 Produce Quality Meter is useful for a wide range of fruits and vegetables.

- F-751 Avocado Quality Meter uses dry matter estimation as a measure of oil content, the indicator of quality in avocados.

- F-751 Mango Quality Meter works along the same principles as the Produce Quality Meter but is customized for popular varieties of mangoes.

- F-751 Kiwi Quality Meter is customized for varieties of kiwi.

The Quality Meters for avocados, mangoes, and kiwis can be used with Fruit maps to benefit from local information.

Type of Fruits

Non-climacteric fruits cannot be stored long at room temperatures, as the fruits are nearly fully ripe at harvest. After a few days or, at maximum, a few weeks, the fruits will start to decay and spoil, so they have to be sold quickly or frozen if used as fresh produce. Excess harvest has to be processed into jams, pickles, juices, concentrates, etc. Berries, grapes, and citrus are examples of non-climacteric fruits.

Climacteric fruits, such as apples and bananas, can be harvested at maturity before they ripen. Their ripening can be postponed by controlling the atmospheric conditions in which they are stored. They can be ripened later when needed. In the last stage, they can be kept in ripening rooms where atmospheric conditions can be altered to trigger ripening.

Cold Storage

One of the most commonly used methods to extend storage time is using cold temperatures as soon as possible. It reduces the rate of respiration in fruits that can produce heat and carbon dioxide. An increase in carbon dioxide and decrease in oxygen usually cause fermentation and spoilage of most fruits and vegetables. (In some exceptional cases, high carbon dioxide and low oxygen concentrations can improve storage). Low temperatures also reduce water loss from fruits and slow the production of ethylene.

Cold storage is a convenient method, as the containers can be small fridges or large rooms, depending on the scale of operation and stage of the supply chain.

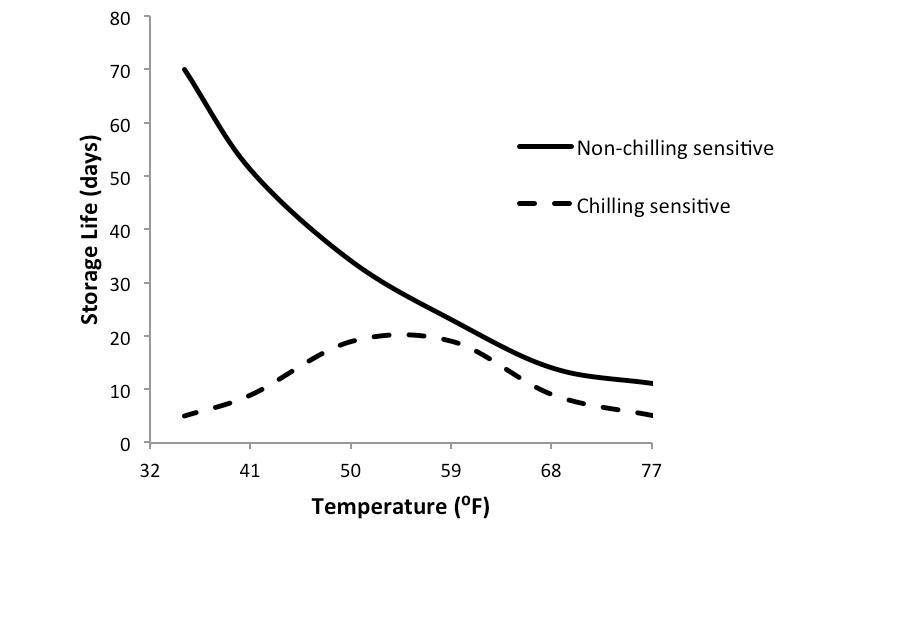

The same temperatures cannot be used for all products. Some are sensitive to chilling and can develop injuries, so they have to be stored between 45-640F (7.2-17.70C); these are usually tropical and sub-tropical in origin, such as tomatoes, potatoes, muskmelons, watermelons. Products that are not sensitive to chilling can be stored for a longer time than chilling sensitive products at low temperatures, see Figure 2. Apples, blackberries, beans, Brussel sprouts, etc. are non-chilling sensitive and can be stored frozen for an extended period.

During cold storage, the temperature, humidity, and levels of three gases—carbon dioxide, oxygen, and ethylene—have to be regulated. There are portable and fixed devices that can collect and monitor atmospheric data to help achieve the precise conditions necessary. Felix Instruments produced the following examples of such devices:

- F-901 AccuStore can be installed for continuous monitoring, as well as regulation of gases.

- F-940 Store It! Gas Analyzer is a portable device suitable for measuring the three gases in storage rooms.

- F-950 Three Gas Analyzer is also portable and measures all the three gases, giving combined readings within seconds.

Figure 2: Length of storage time for chilling and non-chilling sensitive fruits. (Image credits: https://vegnet.osu.edu/sites/vegnet/files/imce/stored_fruit_veg.pdf)

Modified Atmosphere Packaging

Fruits and vegetables can be packed in modified atmosphere packaging (MAP) to extend storage time and avoid loss of chilling sensitive products in cold storage. To dampen the metabolic processes in MAP, the levels of carbon dioxide are high and levels of oxygen are low.

For example, peaches in MAP could be stored for twenty-eight days with little loss in firmness and taste. However, without MAP, the peaches in cold storage showed a significant softening, weight loss, and decay in just fourteen days.

Instruments are available to track the internal atmosphere in the MAP and check for gas accumulation in the headspace above the packs.

- The F-920 Check It! Gas Analyzer is an example that can measure all three gases not only in cold storage but also in other stages of the supply chain. It comes with an injection port kit to sample the internal atmosphere of the MAP.

- F-900 Portable Ethylene Analyzer can also measure carbon dioxide and oxygen. It is very sensitive to low levels of ethylene and records its release from even a single fruit.

Ripening Rooms

In the last stages of storage, fruits and vegetables can be ripened artificially by supplying ethylene. This can be done in simple storage rooms or in advanced ripening rooms built for the purpose. It is easy to control temperature, humidity, and levels of all three gases, including ethylene, in ripening rooms.

The stacking of pallets and boxes, which influence air movement, has to be optimum.

Here again, data can be collected and analyzed with handheld and fixed devices for precise management of temperatures.

- The F-901 AccuRipe is a fixed device, which can be installed inside ripening rooms. It monitors gas levels and regulates the delivery of gases in storage and ripening rooms.

- The F-960 Ripen It! Gas Analyzer is a portable device that gives a combined reading of oxygen, carbon dioxide, and ethylene in ripening rooms. It can be used within the storage space or from the outside, provided there is an internal connection. This way staff exposure to high levels of carbon dioxide can be avoided.

Advantages of Portable Devices

The small analytical tools replace cumbersome and expensive gas analysis and gas chromatography methods used to collect data on storage conditions. By providing accurate technology in portable devices, their application has increased, resulting in safer fresh produce storage. It is possible to reduce food loss significantly if these instruments were used widely. Besides technology, management strategies—such as planning, communication, and transparency—go a long way in the efficient storage and delivery of fresh produce.

—

Vijayalaxmi Kinhal

Science Writer, CID Bio-Science

Ph.D. Ecology and Environmental Science, B.Sc Agriculture

Sources

Albrecht, J. Safe Food Storage. Retrieved from https://food.unl.edu/food-storage

De Sanatana, L.R.R., Benedetti, B.C., Sigrist, J.M.M., & Sarantopoulos, C.I.G.L. (2010). Modified atmosphere packaging extending the storage life of ‘‘Douradao Peach.”

Rev. Bras. Frutic., Jaboticabal – SP, 32, 1009-1017. Retrieved from http://www.scielo.br/pdf/rbf/v32n4/aop13010.pdf

Definition of Food Storage. Retrieved from https://www.definitions.net/definition/FOOD+STORAGE

FAO. SAVE FOOD: Global Initiative on Food Loss and Waste Reduction. Retrieved from http://www.fao.org/save-food/resources/keyfindings/en/

Kendall, P., & Dimond, N. Food Storage for Safety and Quality. Retrieved from https://extension.colostate.edu/docs/pubs/foodnut/09310.pdf

Watkins, C. B., & Nock, J.F. (2012). 2012 Production Guide for Storage of Organic Fruits and Vegetables. NYS IPM Publication No. 10. Retrieved from https://vegnet.osu.edu/sites/vegnet/files/imce/stored_fruit_veg.pdf

Related Products

- F-751 Grape Quality Meter

- Custom Model Building

- F-901 AccuRipe & AccuStore

- F-751 Melon Quality Meter

- F-751 Kiwifruit Quality Meter

- F-750 Produce Quality Meter

- F-751 Avocado Quality Meter

- F-751 Mango Quality Meter

- F-900 Portable Ethylene Analyzer

- F-950 Three Gas Analyzer

- F-920 Check It! Gas Analyzer

- F-960 Ripen It! Gas Analyzer

- F-940 Store It! Gas Analyzer

Most Popular Articles

- Spectrophotometry in 2023

- The Importance of Food Quality Testing

- NIR Applications in Agriculture – Everything…

- The 5 Most Important Parameters in Produce Quality Control

- Melon Fruit: Quality, Production & Physiology

- Guide to Fresh Fruit Quality Control

- Liquid Spectrophotometry & Food Industry Applications

- Ethylene (C2H4) – Ripening, Crops & Agriculture

- Fruit Respiration Impact on Fruit Quality

- Active Packaging: What it is and why it’s important