October 21, 2020 at 9:23 pm | Updated May 2, 2022 at 7:22 am | 7 min read

Near Infra-red (NIR) spectroscopy is a powerful tool that can make the fresh produce supply more transparent and reduce food waste. Moreover, it can increase competitiveness during price fixation. NIR spectroscopy is now available in portable devices that can monitor the quality of fresh produce which results from conditions they are subjected to in various stages of the whole supply chain. The technology is also useful to control changes in produce quality along the supply chain. Other than farmers, many stakeholders in the supply chain can benefit from the technology, such as distributors, retailers, and consumers.

Non-Destructive Measurements

One of the requirements for quality control is that measurements have to be non-destructive to save fruit and vegetable loss. The conventional methods, such as an oven or micro-oven method of estimation for dry matter or refractometer for sweetness, are not only destructive, but they are also time-consuming and require training to perform the chemical analyses. It also requires sample preparation and space to conduct the tests.

NIR spectroscopy has been miniaturized and is now available in small, portable tools that are user-friendly and simple enough to be used by anyone. The results are available instantly and are precise, without variation, due to differences in laboratory conditions.

Subscribe to the Felix instruments Weekly article series.

By submitting this form, you are consenting to receive marketing emails from: . You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact

There are many NIR spectroscopy devices on the market. For example, consider the following products by Felix Applied Food Science Instruments:

- The F-750 Produce Quality Meter can estimate dry matter, soluble solids content (SSC), titrable acidity, and color. It can be used for a wide range of fruits and vegetables.

- The F-751 Avocado Quality Meter also estimates dry matter and Brix for Haas variety of Avocados. It is used to help determine quality of the fruit to determine harvesting as well as post-harvest.

- The F-751-Mango Quality Meter—which can also estimate dry matter, Brix, and acidity—is customized for mangoes. It has models built for common varieties of mangoes, such as Ataulfo, Tommy K, Kent, Keitt, Calypso, and Honey Gold varieties.

- The F-751 Kiwi Quality Meter is another quality meter based on the F-750 and is useful to measure maturity and ripeness indicators in the whole supply chain for kiwis.

The Supply Chain

NIR spectroscopy is a well-established method to measure quality and maturity indicators, such as dry matter content and total soluble solids. The dry matter at harvest is a good predictor of ripe fruit post-harvest. However, there are many steps between harvest to sales that can also influence fresh produce quality.

Once fresh produce is harvested, they are cleaned, sorted, packaged, transported, and treated before they are finally on display in the retail shops as commodities.

The fruits and vegetables are alive, and their characteristics continue to change during this entire process. So, NIR spectroscopy is useful as a quality control measure in all of these phases.

For example, the ripeness of Barhi dates is evaluated by BRIX, crunchiness, hardness, and development of yellow color. NIR spectroscopy could identify all the five ripening stages in dates using SSC and moisture content. The relation of color with the five stages was less dependable. It is possible to sort the Barhi dates using these characteristics.

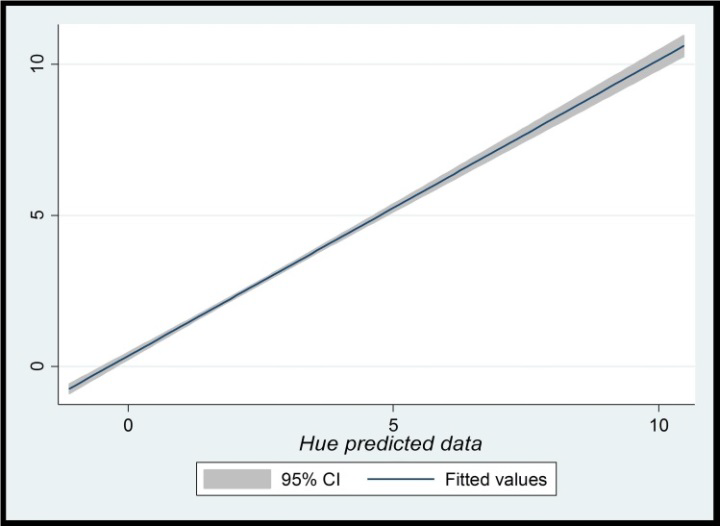

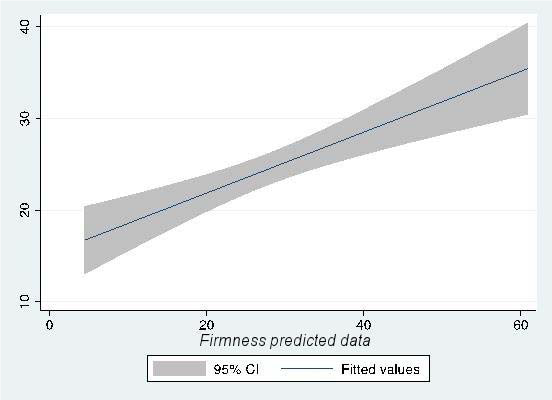

The technology is not used evenly across all categories of fresh produce. The extent to which the spectrometers can be used depends on the species and the parameter that is being estimated, see Figure 1.

Figure 1: NIR spectroscopy can predict the color far more accurately than firmness in the case of table olives, Vallone et al., 2019. (Image credits: https://www.aidic.it/cet/19/75/014.pdf)

Fruit Ripening

The soluble sugar content (SSC), titrable acidity, internal color, and firmness are the parameters of interest in gauging ripeness in fruits.

- SSC: Of all these parameters, SSC is the one that is the industry standard. Besides reflecting fruit physiology, SSC content has proven to be a good indicator of consumer preference. So, it is used in apple, pear, plum, tomatoes, citrus fruit, kiwi, melon, cherry, etc.

- Titratable acidity: Sweetness is only one of the essential criteria to judge taste and consumer preference. Often a balance between sugars and acids is preferred for the best flavor. Hence, the titratable acidity of many fruits is measured to calculate the sugar to acidity ratio. NIR can successfully measure acidity in apple, oranges, tomatoes, peaches, nectarines, and pineapples.

- Firmness: NIR can detect the ideal firmness of ripe fruits in the case of mangoes, tomatoes, and apples. However, it is less effective in the case of table olives, see Figure 1.

- Color: Internal and external color development is essential to monitor. Here, NIR is suitable for table olives, apples, mango, and tomatoes.

Nutrient Content of Fresh Produce

Many of the fresh produce are gaining importance as nutraceuticals due to the high levels of nutritious phytochemicals that they contain. These could be antioxidants, vitamins, polyphenols, pigments like carotenoids, etc. Many fresh produce are tested with NIR spectroscopy to check the concentration of these nutrients. Produce commonly examined for this reason include blueberries, raspberries, strawberries, banana, carrots, oranges, potatoes, eggplants, olives, etc.

Fruit Grading and Sorting

Ripeness parameters are checked several times in the supply chain to sort fruits at different stages.

Climacteric fruits are picked when they are mature but not completely ripe, while non-climacteric fruits are harvested when almost fully ripe. Before they are packed, they are sorted and graded according to size, shape, and stage of ripeness, see Figure 2.

NIR-based tools are useful to sort fresh produce according to their ripeness indicators. For example, when tomatoes are mixed and not sorted, there is a 10% loss of harvest. Ripe or decaying tomatoes produce ethylene, which can prematurely ripen green vegetables in the same pack, spoiling more crop yields.

Sorting is carried out again during storage and retailing to remove spoiled produce. Sorting allows for early sales of ripe fruits and later sales of unripe products.

Figure 2: Sorting bell peppers before packing, FAO. (Image credits: http://www.fao.org/3/I9610EN/i9610en.pdf)

Authentication of Products

NIR spectrometers can be used in many ways to detect fraud in the market. Some of the important uses are to find out the following:

- Area of origin: To find the geographical origin of products, such as honey or coffee.

- Farming methods: To distinguish food produced through conventional farming from organic products produced without pesticides. Organic food is usually more expensive and commands premium prices. One of the challenges, which retailers and suppliers of organic food face, are to avoid the mixing of conventional and organic products, which can happen accidentally or with intent. NIR spectroscopy can be used to detect the compounds used in pesticides.

- Identify protected varieties: Some varieties have to undergo special treatments post-harvest to fulfill strict product specifications. For example, the Annurca apples from Italy must undergo an expensive reddening process (melaio) to improve peel color and flavor. Sometimes, the melaio step is skipped to spare costs, but in these cases, the apples do not qualify to be labeled as ‘Melannurca Campana PGI.’ NRI spectroscopy can spot apples that have received the melaio treatment. The ability to distinguish the treated apples is greatest before storage. After the fruits are subjected to low temperatures and the controlled atmosphere in the cool rooms, the prediction rate can decrease from pre-storage rates of 93.3% to 70%.

Storage Conditions

Storage conditions of low temperature and controlled gases, as well as the length of time, can influence quality. On the other hand, storage conditions can affect the range of time fruits can be stored.

When fruits are stored in cold temperatures, the length of time they can be stored increases as the production of ethylene decreases. However, care should be taken to see that temperatures do not drop too low; otherwise, it can cause chilling injury. So, the ideal temperature conditions are between 45-64F (7.2-17.70C).

Using NIR spectroscopy, it is possible to find out how long each species and variety can be stored in different storage atmospheres without effecting quality. For example, Barhi dates can be stored for 20, 40, and 120 days when they are kept in ordinary rooms, cold, and CA storage, respectively.

Conversely, the best storage method—regular, cold, or controlled atmosphere for fruits—can be chosen based on the time left to sell them.

Assessment for Retailing

NIR spectroscopy tools can help retailers in quality control by detecting internal defects in two ways:

- Avoid spoiled produce: The NIR devices are used to evaluate internal quality to affirm that the fresh produce is not over-ripe or bruised. Storage disorders in kiwi, water core in apples, or problems in mangosteen have also been identified by NIR not just during retailing but also in earlier stages of the supply chain.

- Reject products with diseases or pests: Many fungal infections result in toxins that can be estimated accurately by NIR. Internal pest larvae inside whole, healthy-looking fruits and problems like the brown heat in pears or drying in tangerines can also be spotted by NIR.

NIR helps retailers remove damaged goods to maintain their reputation and also to prevent loss in the rest of the product due to the spread of diseases and pests or ethylene. Moreover, by controlling the quality of products and determining authenticity, NIR can be valuable in price-fixing.

Wider Applications are Possible

Research into the applications of NIR spectroscopy in the post-harvest stages is being conducted globally. However, NIR spectroscopy is not used widely in practice. The fresh produce supply chain has yet to realize the potential of this new technology. NIR devices can help in decision-making to reduce food loss, control quality, and fix prices in various critical points of the supply chain.

—

Vijayalaxmi Kinhal

Science Writer, CID Bio-Science

Ph.D. Ecology and Environmental Science, B.Sc Agriculture

Feature image courtesy of U.S. Department of Agriculture

Sources

Alhamdan, A. M., & Atia, A. (2017). Non-destructive method to predict Barhi dates quality at different stages of maturity utilising near-infrared (NIR) spectroscopy. International Journal of Food Properties, 20(sup3). doi: 10.1080/10942912.2017.1387794

Alhamdan, A. M., Fickak, A., & Atia, A. R. (2019). Evaluation of sensory and texture profile analysis properties of stored Khalal Barhi dates nondestructively using Vis/NIR spectroscopy. Journal of Food Process Engineering, 42(6). doi: 10.1111/jfpe.13215

Buccheri, M., Grassi, M., Lovati, F., Petriccione, M., Rega, P., Scalzo, R. L., & Cattaneo, T. M. (2019). Near infrared spectroscopy in the supply chain monitoring of Annurca apple. Journal of Near Infrared Spectroscopy, 27(1), 86–92. doi: 10.1177/0967033518821829

Giovanelli, G., Sinelli, N., Beghi, R., Guidetti, R., & Casiraghi, E. (2014). NIR spectroscopy for the optimization of postharvest apple management. Postharvest Biology and Technology, 87, 13–20. doi: 10.1016/j.postharvbio.2013.07.041

Sánchez, J. C. (2012). Using near-infrared spectroscopy to predict postharvest quality. CAB Reviews: Perspectives in Agriculture, Veterinary Science, Nutrition and Natural Resources, 7(021). doi: 10.1079/pavsnnr20127021

Vallonea, M., Alleria, M., Bonob, F., & Cataniaa, P. (2019). Use of a Portable vis Nir Device to Predict Table Olives Quality. Chemical Engineering Transactions, 76: 79-84. DOI: 10.3303/CET1975014

Wigati, L. P., Sutrisno, & Darmawati, E. (2019). Losses and waste of tomato and red chilli along the supply chain. IOP Conference Series: Earth and Environmental Science, 230, 012001. doi: 10.1088/1755-1315/230/1/012001

Related Products

- F-751 Grape Quality Meter

- Custom Model Building

- F-901 AccuRipe & AccuStore

- F-751 Melon Quality Meter

- F-751 Kiwifruit Quality Meter

- F-750 Produce Quality Meter

- F-751 Avocado Quality Meter

- F-751 Mango Quality Meter

- F-900 Portable Ethylene Analyzer

- F-950 Three Gas Analyzer

- F-920 Check It! Gas Analyzer

- F-960 Ripen It! Gas Analyzer

- F-940 Store It! Gas Analyzer

Most Popular Articles

- Spectrophotometry in 2023

- The Importance of Food Quality Testing

- NIR Applications in Agriculture – Everything…

- The 5 Most Important Parameters in Produce Quality Control

- Melon Fruit: Quality, Production & Physiology

- Guide to Fresh Fruit Quality Control

- Liquid Spectrophotometry & Food Industry Applications

- Ethylene (C2H4) – Ripening, Crops & Agriculture

- Fruit Respiration Impact on Fruit Quality

- Active Packaging: What it is and why it’s important