February 2, 2021 at 10:45 pm | Updated February 2, 2021 at 10:45 pm | 6 min read

Scientists used the portable F-750 Produce Quality Meter, an industry-standard, to test if NIR Spectroscopy can be useful in measuring the maturity of unopened cotton bolls. This was part of a series of experiments to explore a novel application of NIRS, with the potential to increase cotton yield per acre.

Setting Single Harvest Date for Indeterminate Cotton

Cotton shows indeterminate flowering, and bolls on a single plant are at different stages of maturity from the bottom to the top.

Though the process is time-consuming, small farm owners who pluck bolls by hand have the chance to make repeat harvests. In contrast, large farms that use cotton farming technology like machine harvesters, can only harvest once as the entire plant is destroyed in the harvesting process. In the USA, for example, cotton is grown on farms that are, on average, 200 acres large and holdings of up to 500 acres are not uncommon, so these methods must be used to harvest efficiently.

Subscribe to the Felix instruments Weekly article series.

By submitting this form, you are consenting to receive marketing emails from: . You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact

To be able to use cotton farming technology only once to collect the bolls, it is necessary to check if all bolls are mature to maintain cotton yield per acre.

Two scientists, Long and Bange, endeavored to find a way to check maturity easily, regardless of the size of the farm, to optimize harvest timing with the use of cotton farming harvest technology.

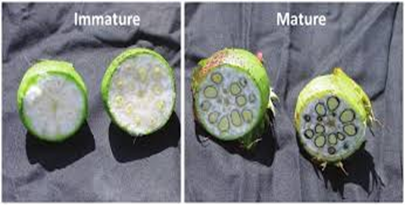

Figure 1: Boll-cutting technique to check for maturity, Long and Bange, 2020. (Image credits: https://doi.org/10.1177/0967033520911463)

Challenge: Find A Non-Destructive Method of Estimating Cotton Boll Maturity

Traditionally, farmers use the boll-cutting technique to estimate cotton maturity. Bolls are manually cut into equal halves at the equator of the fruit. Bolls with dark seed coat and tan colored seeds indicate that the fruit is ready to dehisce and is considered to be physiologically mature; see Figure 1. Farmers fix the harvest date by using this information in combination with the number of nodes on the main stem where the bolls are borne.

Knowing the extent of crop maturity also allows growers to make decisions about final irrigation needs to maximize cotton yield per acre.

However, the boll-cutting technique is time consuming, and using a sharp knife in the open fields can lead to injuries. Moreover, this method is destructive, as tested bolls are discarded, leading to lower cotton yield per acre.

Therefore, Long and Bange wanted to find a method that was non-destructive, fast, and reliable.

They decided to do so by focusing on the biochemical changes in the fruit that occur during boll formation. As bolls grow, there are increases in carbohydrate and protein levels in the seeds and cellulose accumulation in the single-celled strands of cotton fiber.

Near-infrared (NIR) is a band of light that is commonly used to quantify compounds in a plant, as it interacts with them to produce different spectra based on the composition of samples. NIR spectroscopy (NIRS) used to measure the spectra is accurate and reliable.

Traditionally, NIRS devices have been large, laboratory-bound units, requiring experienced personnel to operate them. Recently, the technology has been miniaturized into NIR devices that are small enough to be used easily in the field while providing the same level of accuracy and reliability as their predecessors.

Solution: The Felix F-750 Produce Quality Meter

Figure 2: “Cotton boll being held in position for spectral acquisition against the collecting window of a Felix F-750 Produce Quality Meter. The diameter of the window is 26 mm,” Long and Bange, 2020. (Image credits: https://doi.org/10.1177/0967033520911463)

Long and Bange decided to use the F-750 Produce Quality Meter. A portable NIR device, manufactured by Felix Instruments – Applied Food Science, which has been designed for farm use to take non-destructive measurements of whole fruits on plants. This way they could avoid the need to cut and destroy bolls.

In an earlier experiment, the scientists had already calibrated the F-750 to measure cotton maturity in the laboratory.

Given the light and temperature variables present in in-situ testing, the scientists now wanted to learn whether there would be a difference in laboratory vs. field measurements of data. They also examined several other factors that could influence maturity estimation, such as the size of the boll and the influence of external skin. Whether the composition of cotton bolls was homogeneous throughout the fruit and whether the position of measurement on the fruit would affect maturity readings was also examined.

Additionally, the scientists wanted to find out if tool features, such as light intensity, light source, and the size of the lens used in F-750, were the best possible ones to use for cotton.

The experiment, conducted in Australia, tested bolls from six populations on six different days, with bolls taken from different heights of the cotton plant.

Using different default settings, they collected data in the morning from bolls on the plants, at different positions on the fruits. The Felix F-750 took eight scans in each measurement to give an average spectrum. The NIRS device had a wavelength range of 310–1100 nm and spectral resolution of 8–13 nm.

Then, the scientists harvested the same bolls and cooled them through air-conditioning to test them in the laboratory, as shown in Figure 2.

Finally, the bolls were used in the boll-cutting technique to compare the readings with measurements of the NIRS device.

Benefits of the Felix F-750 Produce Quality Meter

The F-750 is designed to minimize the effects of stray sunlight and changes in lighting, making it ideal for use in field, as well as the laboratory.

Though the F-750 is small and portable, it is an industry-standard manufactured by Felix Intruments- Applied Food Science, known for its accuracy. It has been used globally for many fruits and animal products, making it a natural choice when investigating NIRS application on both food and non-food farm products.

Moreover, the F-750 has a model building software, with easy to follow instructions, to extend its use to new varieties, species, or locations. This aspect of the tool was very important for the experiment during calibration, validation, and model-building steps of chemometrics.

The F-750 NIRS device uses both NIR and visible light, so the scientists could test the effects of both light bands and were able to eliminate visible light spectroscopy without conducting another separate experiment.

The NIRS device can measure total soluble solids, dry matter, internal color, and external color within 7 seconds for each sample.

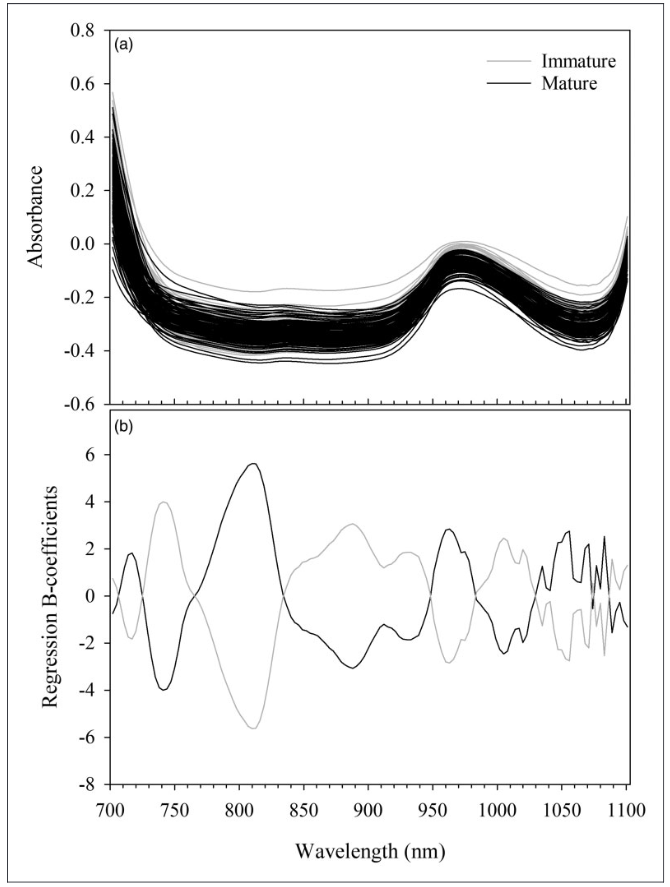

Figure 3: “(a) Absorbance spectra for population C1 (n ¼ 201, field-collected spectra, position A, no pretreatments), and (b) the regression B-coefficients for the relevant partial least squares calibration undertaken using the spectra in (a). Black colored traces represent mature boll data, and grey colored traces represent immature boll data,” Long and Bange, 2020. (Image credits: https://doi.org/10.1177/0967033520911463)

Portable NIRS Can Determine Maturity of Cotton Bolls

The scientists used the absorbance spectra and a Partial Least Squares (PLS) model to analyze cotton bolls. Calibration models considered location (field or laboratory) and testing position on bolls.

They found the best spectra for maturity determination were 840 and 940 nm, as shown in Figure 3B.

The F-750 NIRS device could be calibrated and validated with high accuracy of 96%,for two levels of boll maturity: immature and mature. The scientists, Long and Bange, attribute this to cotton’s high

concentrations of cellulose content, which increases in time. Hence, they concluded that NIRS is sensitive to cellulose content.

The scientists found that size of the fruit had no influence, and NIR could penetrate the bolls, possibly to a depth of 5 mm. There were also no major changes in the external skin, so the changes significant for maturity arise from the composition of the bolls.

The NIRS device seems to be ideal for field measurements of maturity, as the measurements did not differ from estimations made in controlled laboratory conditions. There were no significant differences in measurements due to position, indicating that the boll composition is homogeneous. Therefore, bolls can be tested at any place, making the application of NIRS more flexible in the field.

As a result, the scientists were able to recommend the in-field use of the F-750 Produce Quality Meter to determine the maturity of unopened cotton bolls.

More Studies Required to Fine-Tune NIRS Use for Cotton

The scientists recommend more studies with the F-750 to extend its use in the fields for real-life farm management. They want to test the NIRS predictions over a range of seasons, sites, and cultivars so that a robust model can be suggested for practical use. They also want to explore the possibility of combining the NIRS device in robotic applications for constant in-field monitoring of boll maturity to increase the cotton yield per acre.

—

Vijayalaxmi Kinhal

Science Writer, CID Bio-Science

Ph.D. Ecology and Environmental Science, B.Sc Agriculture

Feature image courtesy of Alabama Extension.

Sources

Long, R. L., & Bange, M. P. (2020). Measuring the maturity of unopened cotton bolls with near infrared spectroscopy. Journal of Near Infrared Spectroscopy, 28(4), 204-213. DOI: https://doi.org/10.1177/0967033520911463

Related Products

- F-751 Grape Quality Meter

- Custom Model Building

- F-901 AccuRipe & AccuStore

- F-751 Melon Quality Meter

- F-751 Kiwifruit Quality Meter

- F-750 Produce Quality Meter

- F-751 Avocado Quality Meter

- F-751 Mango Quality Meter

- F-900 Portable Ethylene Analyzer

- F-950 Three Gas Analyzer

- F-920 Check It! Gas Analyzer

- F-960 Ripen It! Gas Analyzer

- F-940 Store It! Gas Analyzer

Most Popular Articles

- Spectrophotometry in 2023

- The Importance of Food Quality Testing

- NIR Applications in Agriculture – Everything…

- The 5 Most Important Parameters in Produce Quality Control

- Melon Fruit: Quality, Production & Physiology

- Guide to Fresh Fruit Quality Control

- Liquid Spectrophotometry & Food Industry Applications

- Ethylene (C2H4) – Ripening, Crops & Agriculture

- Fruit Respiration Impact on Fruit Quality

- Active Packaging: What it is and why it’s important