August 5, 2021 at 1:18 am | Updated April 11, 2022 at 6:44 am | 6 min read

An increase in the import of mangos into Europe makes it necessary to find accurate and rapid methods of testing ripeness. Though subjective, firmness is one of the oldest and most intuitive means of judging fruit ripeness. Emerging work with NIR spectrometers can make this subjective process more objective and help in establishing the correct combination of conditions for ripening and storing. To optimize firmness measurement, the analysis made by NIR spectrometers was improved for ‘Kent’ Mangos.

Mango Firmness Measurement

Mangos are an important cash crop and export commodity. Over a million tonnes of fruit are exported each year, and Europe is an important destination zone.

Suppliers and producers take advantage of the fact that mango is a climacteric fruit; it needs to be harvested when it is physiologically mature but still unripe, allowing two to three weeks for transport. This has the added advantage of preserving fruit quality during transportation, as hard and green mangos suffer less damage. Once it reaches its destination in Europe, the fruits are ripened artificially using ethylene gas, so that they are “ready to eat” ripe.

Subscribe to the Felix instruments Weekly article series.

By submitting this form, you are consenting to receive marketing emails from: . You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact

One of the most common methods to monitor and judge ripeness is softening of the fruit flesh. Fruits become soft because of biochemical and physical changes. Structural integrity declines and starch is broken down by enzymes to sugars. Not only do the fruits become softer, but they also become sweeter and change color.

Being able to take firmness measurements quickly would allow suppliers to take time-sensitive decisions about the storing conditions of the mangos.

At present, ripeness is monitored by destructive methods to measure total soluble solids (TSS). Tracking of firmness is also destructive during ripening, as it is usually done with penetrometers. Mangos coming from different areas will be in different stages of maturity, and there can be variations in quality within a batch. Using destructive methods of firmness measurements results in high numbers of wasted fruit due to frequent tests, and these methods also involve a lot of time and effort.

NIR Spectroscopy in Mango

Therefore, the use of visible and near-infrared (NIR) spectroscopy to analyze the quality of mangos by non-destructive measurements is becoming widespread.

The NIR light bands react with the bonds that hydrogen forms with carbon, nitrogen, and oxygen. Based on the composition and quantities of the compounds in a sample, the distinct spectra they produce due to interaction with NIR light can be measured by spectrometers. The spectra produced by NIR spectroscopy can have multiple and overlapping peaks because numerous parameters are measured during testing. Analysis of this multivariate data is not simple, and chemometric methods that combine statistical models and computers are used to extract meaningful information from the spectra.

NIR spectroscopy has been used to estimate dry matter, TSS, and flesh color in mangos.

However, checking firmness remains the most common method, and people have accumulated experience in applying it for fruit processing. Hence, a group of scientists endeavored to find a NIR spectroscopy-based non-destructive measurement method to quickly and accurately estimate the firmness of mangos. Using cutting-edge measurement tools, they began developing a specific chemometric model for the purpose.

Developing a Method to Analyze Firmness with NIR

A team of food and horticultural scientists at Wageningen University in the Netherlands experimented with ‘Kent’ mango that is widely exported. They wanted to find how useful Partial Least Squares Regression (PLSR), a commonly used chemometric method, would be in dealing with the Vis-NIR spectra obtained from mangos.

The prediction results for firmness, obtained from the new model they developed, were compared with actual firmness measurements made by the reference method, which was acoustics-based.

Collecting NIR Spectral Data

To be able to develop the model, the scientists had to collect spectral data during the mango ripening process. Fifty Mexican Kent mangos, which were part of a batch that traveled for 21 days at a temperature of 9 °C, were chosen. The experiment was conducted during the ten days when they were being ripened at 20 °C and relative humidity (RH) of 85%, after arrival in the Netherlands.

Non-destructive firmness measurements of the mangos were made by a portable NIR spectroscopy-based device, the F-750 Produce Quality Meter. The device uses a Carl Zeiss MMS-1 spectrometer to measure the reflectance of light in the range of 310–1130 nm. The source of light is a Xenon Tungsten Lamp.

To collect the spectral data, the scientists placed the fruit on the sample holder and pressed the scan button. Spectra were collected at two lateral spots on the mangos, and six scans were made at each spot. Later, acoustic-based measurements were made at the same two spots for each mango. Spectra for mangos were measured on five alternating days. In total, 250 spectra ( 50 mangos x 5 days) were collected. The corrected raw reflectance data was extracted as excel files, using the Felix “Data-Viewer” software.

A total of 250 acoustic-based reference measurements were also made.

Chemometric Modeling

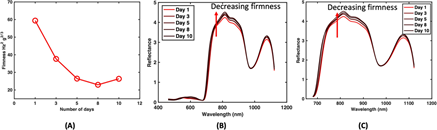

Figure 1: “(A). Change in mango firmness along the storage days. (B). Change in the average VNIR spectra of mango in spectral range of 400–1135 nm. (C). Change in the average NIR spectra of mango in spectral range of 700–1135 nm,” Mishra et al., 2020. (Image credits: https://www.sciencedirect.com/science/article/pii/S1350449520305077)

All mango varieties do not change color with firmness, and color change can differ. Hence, the visible range was excluded at the beginning of the analysis itself and only NIR reflectance between 700-1130 nm were considered; see Figure 1 (C). The spectra were preprocessed by Savitzky-Golay smoothing.

Then, the spectral data were divided randomly into two sets. The calibration set included 210 spectra taken from 42 mangos, and the test set included 40 spectra from eight mangos.

The scientists selected a set of variables and developed an initial PLSR model and found the variance (R2) and root mean squared errors (RMSE) that best explained the results.

However, the spectra from samples will explain various parameters like sugar content, water content, color, firmness, etc. The PLSR models take into account the co-linearity that exists in the spectral data, and select variables that best explain the variation in the spectra. To be able to get a model that focuses on predicting firmness, the scientists decided to identify the wavelengths that best explained firmness and leave out the other wavelengths that are more useful to explain additional quality parameters. This could make the model simpler by using fewer variables, while being more powerful in terms of estimating firmness. The scientists used the interval Partial Least Squares Regression (iPLSR) method to identify the relevant variables for firmness.

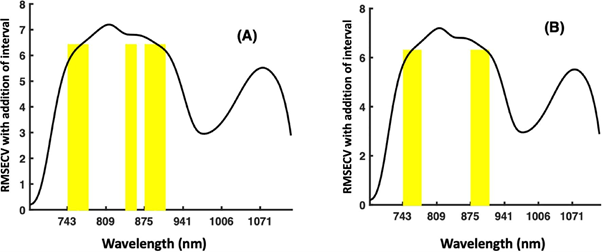

Using the iPLSR method, the scientists divided the full spectrum into small sub-intervals; two window sizes of five and ten were used to test how the interval size affected model prediction. Then, models were developed using the various sub-intervals, and the results were compared to the initial PLSR model. The sub-intervals that produced the least prediction errors were chosen. In this experiment, the scientists were able to identify two sub-intervals of NIR bands for firmness measurements, 743–770 nm and 870–905 nm, which were common for both window sizes; see Figure 2.

Figure 2. “Selected intervals with interval partial least-squares regression (PLSR). (A). Window size of 5, and (B). Window size of 10. The vertical lines are the spectral regions selected by the iPLSR,” Mishra et al., 2020. (Image credits: https://www.sciencedirect.com/science/article/pii/S1350449520305077)

Advantages of using Specific Wavelength Intervals

By using variables selected by iPLSR, the scientists got a model with R2p = 0.75 and prediction error of RMSEC = 5.92 Hz2g2/3; while the standard PLSR model had a R2p = 0.67 and a RMSEC = 6.88 Hz2g2/3.

By reducing the number of wavelengths, the scientists had improved the prediction of the model. Using the two spectral bands of 743–770 nm and 870–905 nm selected by iPLSR, there was a 12% improvement in variance (R2) and 14% reduction in prediction error compared to the initial (standard) PLSR model that used the entire NIR wavelength range. The scientists were also able to identify that the 743–770 nm corresponded to the overtones of C-H and CH2, and the 870–905 nm to overtones of CH2 and CH3. These are compounds that are usually associated with firmness: sugar, hemicellulose, and pectin.

Since more than one band was needed to predict firmness, the scientists concluded that more than one chemical or physical process is responsible for changes in firmness in mangos. This accurately reflects the changes known to occur during ripening in mangos, including changes in color, sweetness, and texture.

The firmness predicted by the new iPLSR model closely followed the changes in firmness, measured by the reference acoustic method. The scientists are interested in collecting spectra of an extended light band between 400-2500 nm to better understand all the biochemistry processes underlying firmness, which they found was not possible with the current model. However, it was interesting to see how well they could correlate the selected bands with changes in chemicals, sugar, hemicellulose, and pectin.

Helping the Mango Supply chain

Mango demand in Europe is increasing year by year, and Kent and Keith remain the most popular imported varieties. The model for improved and non-destructive measurements of firmness in Kent, produced by this study, has immediate applications in the mango supply chain. Especially since the study used an industry standard like the F-750, manufactured by Felix Instruments Applied Food Science. The new model will be useful not only during the ripening process, but also to ensure that the fruits retain their quality during transport or retailing. Since fruits are at different stages of maturity when they arrive in Europe, having a precise and objective means of measuring ripeness will help the industry make the most of the fruits that are imported to boost profits and reduce food loss.

—

Vijayalaxmi Kinhal

Science Writer, CID Bio-Science

Ph.D. Ecology and Environmental Science, B.Sc Agriculture

Sources

CBI. (2021, January, 12). The European market potential for mangos. Retrieved from https://www.cbi.eu/market-information/fresh-fruit-vegetables/mangos/market-potential

Mishra, P., Woltering, E., & Harchioui, N.E. (2020). Improved prediction of ‘Kent’ mango firmness during ripening by near-infrared spectroscopy supported by interval partial least square regression. Infrared Physics & Technology, 110. https://doi.org/10.1016/j.infrared.2020.103459

Related Products

- F-751 Grape Quality Meter

- Custom Model Building

- F-910 AccuStore

- F-751 Melon Quality Meter

- F-751 Kiwifruit Quality Meter

- F-750 Produce Quality Meter

- F-751 Avocado Quality Meter

- F-751 Mango Quality Meter

- F-900 Portable Ethylene Analyzer

- F-950 Three Gas Analyzer

- F-920 Check It! Gas Analyzer

- F-960 Ripen It! Gas Analyzer

- F-940 Store It! Gas Analyzer

Most Popular Articles

- Spectrophotometry in 2023

- The Importance of Food Quality Testing

- NIR Applications in Agriculture – Everything…

- The 5 Most Important Parameters in Produce Quality Control

- Melon Fruit: Quality, Production & Physiology

- Fruit Respiration Impact on Fruit Quality

- Guide to Fresh Fruit Quality Control

- Liquid Spectrophotometry & Food Industry Applications

- Ethylene (C2H4) – Ripening, Crops & Agriculture

- Active Packaging: What it is and why it’s important