October 21, 2020 at 9:24 pm | Updated October 21, 2020 at 9:24 pm | 6 min read

Mangoes are one of the major tropical fruits produced and exported globally. Efficiently producing and supplying fruits can increase profits for the stakeholders in the industry. The use of NIR spectroscopy to measure mango maturity at harvest time by estimating dry matter is well documented. A little known fact is that NIR spectroscopy can also be used post-harvest for mangoes during sorting, packing, and retailing.

NIR Spectroscopy in Mangoes

Mangoes are climacteric fruits that can ripen after harvest. This characteristic is exploited by picking them when they are hard but mature. The external and internal appearance, or hardness, gives no clues to the fruit’s maturity. Hence, the dry matter has long been used as a maturity and quality indicator.

Dry matter is the sum total of all the solids in a fruit, minus its water content. The solids include starch, sugars, proteins, fat, fiber, etc.

Subscribe to the Felix instruments Weekly article series.

By submitting this form, you are consenting to receive marketing emails from: . You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact

The dry matter at harvest has also been found to be a good indicator of post-harvest quality since starch is converted to sugars as the mangoes ripen. Total soluble sugars, or sweetness, that reflects the eating quality of fruits has its own measure: the BRIX.

In mangoes, both dry matter (DM) and BRIX can be measured accurately with near infra-red (NIR) spectroscopy. This technique is non-destructive and replaces older, destructive methods of DM and BRIX estimation.

The oven drying method is the conventional method of estimating DM, and the refractometer is used to measure BRIX. In both cases, many fruits are cut for testing; repeated testing, which is necessary to determine maturity or quality, wastes many fruits. Moreover, the methods are time consuming and they require a laboratory and certain level of skill in conducting the tests.

Uses of Maturity and Quality Indicators in Mangoes

DM is used as the maturity and quality indicator during harvest and during sorting, while total soluble sugars and titrable acidity are used as the quality indicators during post-harvest to measure taste and ripeness.

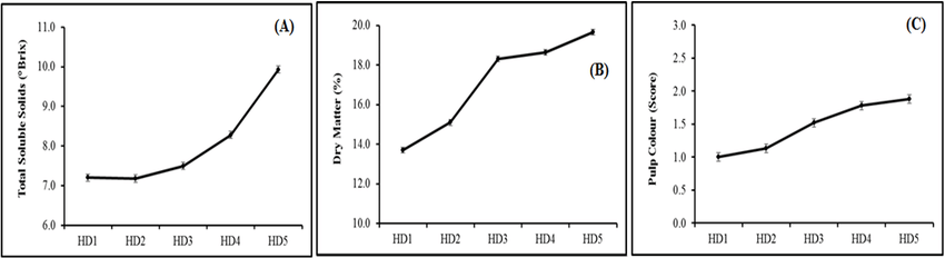

Figure 1: Difference in DM, TSS, and pulp color in ‘Sindhri’ mangoes at different harvest (HD) dates, Amin et al. 2016. (Image credits: DOI: 10.17660/ActaHortic.2016.1111.47)

Harvest Time

The minimum average DM to harvest mangoes is fixed at 14%. DM at full maturity can increase up to 22% if the fruits are left on the trees; see Figure 1. However, Central Queensland University recommends picking fruits earlier to increase transport time. The university favors harvesting when 90% of the fruits sampled reach the recommended average; for example, this is a DM of 16.5% for Calypso and KP in Australia.

The ideal DM to predict harvest time for mangoes, worldwide, falls in the range of 14-16.5%. This typical DM depends not only on the variety of mangoes, but also the region or country where they are grown.

A farm can be divided into blocks if there is a difference in aspect or other environmental conditions on the farm; the average is calculated per block to get a more homogenous harvest quality and do the picking in phases.

Sorting

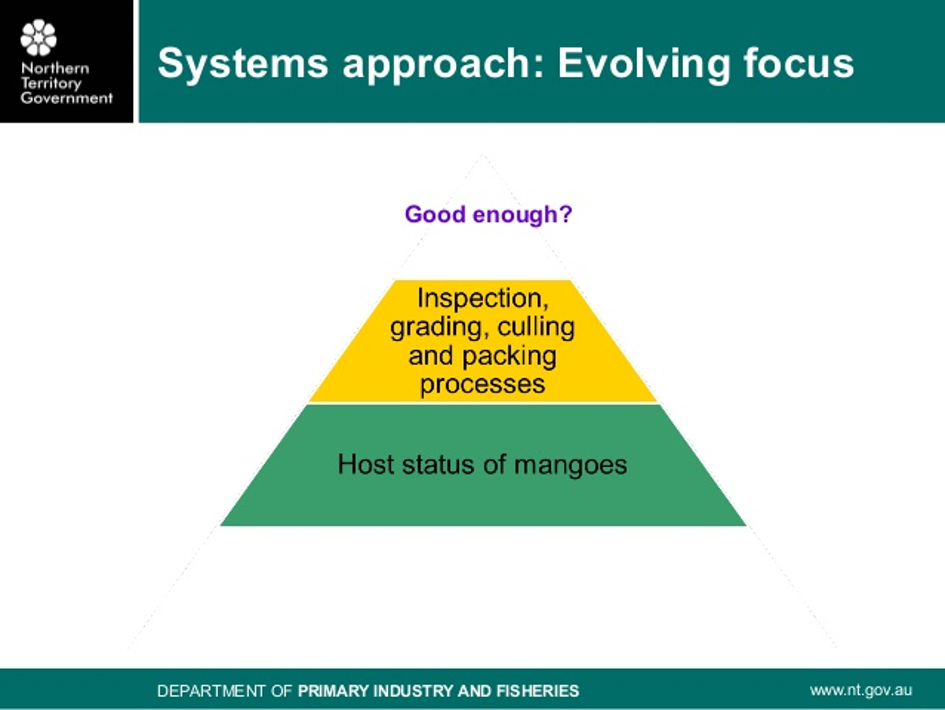

Sorting for fruits takes place at many stages of the supply chain for mangoes: before storage, packaging, and retailing of whole fruits, and processing of fruits; see Figure 2.

- Storage: Mango fruits can be kept for 21 days if they are stored and transported at 10oC. The time of storage can be increased as temperature decreases. However, lowering the temperatures too much can cause chilling damage to the skin and result in fungal diseases. Very low temperatures can also negatively affect the quality of mangoes, by impairing color development, full ripening, and the final total TSS levels. Thus, 7.2-8.8oC (or 45–48oF) is the minimum temperature advisable for fully mature Indian “Alphonsos.”

According to the National Mango Board of USA, storage temperatures should, as an industry thumb rule, never be lower than 10oC for any mango type.

The DM content of fruits at the onset of storage can have a significant impact on fruit quality once removed from warehouses. Research has shown that fruits with higher DM (150 g.kg−1) withstand the cold storage better and show better quality once removed from the cold room than fruits with less DM (110 g.kg−1) in Palmer mangoes. NIR spectrometers can be used to sort fruits during storage so that the quality of fruits is more uniform later. Moreover, sorting at this stage makes more efficient use of cold storage space that is expensive and avoids subsequent wastage. Mangoes with less DM can be diverted for other purposes or sent for processing

- Grading in packing houses: Before the mangoes are parcelled, the fruits are sorted again based on the degree of ripening, which can be done by measuring TSS. Packing houses, therefore, need a non-destructive and rapid method of sorting fruits that is also easy to use. Again, NIR spectrometers tick all the boxes.

- Authentication of varieties: A few famous mango varieties are ecotypes and are endemic to a region; for example, the “Alphonso” is an ecotype from central India and commands a premium price in the domestic, as well as the export, market. These are easily identified and differentiated from closely resembling cultivars like the “Banganpalli” by using dry matter content.

- Retailing: Retailers regularly check fruits for freshness and signs of decay. Frequent, non-destructive, and quick on-the-spot measurements are made possible by portable and handheld NIR spectrometers.

- Processing: Mangoes are processed to make pulp, juice, jams, leather, and dry fruits. The TSS, titrable acidity, and pH that are indicators of the physiochemical conditions of the fruits are preferred as they are precise and objective compared to color charts and firmness.

Since a sizeable portion of the mango crops globally is meant for export, the introduction of DM, TSS, and titrable acidity measurements post-harvest can improve profits and consumer satisfaction. For example, “Tommy Atkins” mangoes are exported by ship to Germany, but due to poor quality and color on arrival, there is little demand for them.

Figure 2: Using DM, TSS, and titrable acidity to sort mangoes. (Image credits: https://www.slideshare.net/AustralianMangoes/mangoes-a-conditional-nonhost-for-fruit-flies-presentation-from-the-10th-australian-mango-conference)

Quality Meters

NIR spectroscopy is a sophisticated technology that has been miniaturized to fit small portable meters that can be used in the farms, sorting and packing houses, warehouses, and laboratories. A beam of light of the chosen NIR spectrum is directed at a fruit. Depending on the compounds and their concentrations, there is a variation in the light that is absorbed, transmitted, or reflected back. These interactions with light are measured to identify the contents and their percentage in the fruit.

Felix Applied Food Science Instruments has several quality meters based on NIR spectroscopy. Two of them can be used for mangoes:

- F-750 Produce Quality Meter was developed at Central Queensland University. It measures DM, TSS, titrable acidity, and color. It can be used for several fresh produce, including mangoes.

- F-751-Mango Quality Meter can also measure the DM, TSS, titrable acidity, and color. The device has been customized for mangoes and has models for “Kent,” “Keitt,” “Calypso,” “Tommy K,” “Ataulfo“ (also known as “Champagne,” “Honey” or “Adolfo”), and “Honey Gold” varieties.

Both instruments can be handled with one hand and give individual measurements within twelve seconds. The devices are user-friendly and easy to use and read. The data from measurements can be stored and categorized according to a single fruit, plant, and plot. The information can be integrated and used with Fruit Maps, the first fruit maturity app available on the global market.

Avoid Waste and Increase Profits

There were 50.65 million metric tons of mangoes that were produced globally in 2017. According to a 2019 Food and Agriculture Organization market review, mangoes make up fifty-two percent of the tropical fruits produced worldwide and make up twenty-three percent of the world trade in tropical fruits. However, the level of loss is also high. In developing countries like Kenya and Bangladesh, nearly forty to fifty percent of mangoes go to waste. Proper harvest, sorting, packing, and storage practices can go a long way in reducing this waste. Instruments like Felix Quality Meters can be used by individual farmers and consultants or shared through farmers’ cooperatives to bring the benefits of state-of-the-art science to the farms and the supply chain for mangoes.

—

Vijayalaxmi Kinhal

Science Writer, CID Bio-Science

Ph.D. Ecology and Environmental Science, B.Sc Agriculture

Feature image courtesy of Prasanth M J

Sources

Altendorf, S. (2019). Major tropical fruits market review 2018. Rome, FAO. Retrieved from http://www.fao.org/3/ca5692en/ca5692en.pdf

Jha, S. N., Jaiswal, P., Narsaiah, K., Kumar, R., Sharma, R., Gupta, M., … Singh, A. K. (2013). Authentication of Mango Varieties Using Near-Infrared Spectroscopy. Agricultural Research, 2(3), 229–235. doi: 10.1007/s40003-013-0068-4

Luca, C. D. (2017, March 23). Factors that influence dry matter. Retrieved from https://www.industry.mangoes.net.au/resource-collection/2017/3/23/factors-that-influence-dry-matter

Malik, A.U., Gayle, M. C., Felipe, L., Pérez-Romero, L. F., & Carlos, C. (2017). Mango Dry Matter Measurement Protocol. Retrieved from https://www.researchgate.net/publication/322153362_Mango_Dry_Matter_Measurement_Protocol

Mango Handling Practices. Retrieved from https://www.mango.org/wp-content/uploads/2017/10/Mango_Handling_Practices_Eng.pdf

Nambi, V., Thangavel, K., & Jesudas, D. (2015). Scientific classification of ripening period and development of colour grade chart for Indian mangoes (Mangifera indica L.) using multivariate cluster analysis. Scientia Horticulturae, 193, 90–98. doi: 10.1016/j.scienta.2015.05.031

Neto, J. P. D. S., Leite, G. W. P., Oliveira, G. D. S., Júnior, L. C. C., Gratão, P. L., Camilo De Lelis Medeiros De Morais, & Teixeira, G. H. D. A. (2018). Cold storage of ‘Palmer’ mangoes sorted based on dry matter content using portable near infrared (VIS-NIR) spectrometer. Journal of Food Processing and Preservation, 42(6). doi: 10.1111/jfpp.13644

Portal, F. (2019, September 8). Overview global mango market – Sept 2019. Retrieved from https://www.farmingportal.co.za/index.php/agri-index/68-crops/3007-overview-global-mango-market-sept-2019

Shahbandeh, M., & Feb. (2020, February 3). Mango production worldwide 2017. Retrieved from https://www.statista.com/statistics/577951/world-mango-production/

Subedi, P., Walsh, K., & Purdy, P. (2013). Determination Of Optimum Maturity Stages Of Mangoes Using Fruit Spectral Signatures. Acta Horticulturae, 992, 521–527. doi:10.17660/actahortic.2013.992.64

Sundararaj, J.S., Muthuswamy, S., & Sadasivam, R. (1972). Storage of mango fruits. Acta Hortic. 24, 265-270. doi: 10.17660/ActaHortic.1972.24.53

Walsh, K., & Subedi, P. (2016). In-field monitoring of mango fruit dry matter for maturity estimation. Acta Horticulturae 1119, 273–278. doi: 10.17660/actahortic.2016.1119.38

Related Products

- F-751 Grape Quality Meter

- Custom Model Building

- F-901 AccuRipe & AccuStore

- F-751 Melon Quality Meter

- F-751 Kiwifruit Quality Meter

- F-750 Produce Quality Meter

- F-751 Avocado Quality Meter

- F-751 Mango Quality Meter

- F-900 Portable Ethylene Analyzer

- F-950 Three Gas Analyzer

- F-920 Check It! Gas Analyzer

- F-960 Ripen It! Gas Analyzer

- F-940 Store It! Gas Analyzer

Most Popular Articles

- Spectrophotometry in 2023

- The Importance of Food Quality Testing

- NIR Applications in Agriculture – Everything…

- The 5 Most Important Parameters in Produce Quality Control

- Melon Fruit: Quality, Production & Physiology

- Guide to Fresh Fruit Quality Control

- Liquid Spectrophotometry & Food Industry Applications

- Ethylene (C2H4) – Ripening, Crops & Agriculture

- Fruit Respiration Impact on Fruit Quality

- Active Packaging: What it is and why it’s important