November 7, 2020 at 5:57 am | Updated November 7, 2020 at 5:57 am | 6 min read

Consumers expect that the fruits and vegetables they buy are of the highest quality. Therefore, more in-depth quality control and sorting systems are increasingly being used to ensure that supplies reaching retailers meet the required standards. Many fruits and vegetables today are still sorted mostly on the basis of external features such as color, size, weight, and blemishes, but consistently meeting quality control demands is possible only when internal parameters are also examined.

Light Spectra Used for In-line Sorting

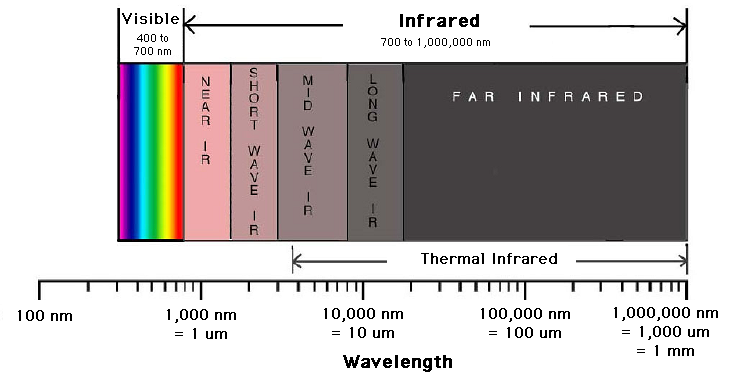

Figure 1: Infrared is 40 times greater than the visible spectrum, Digital Earth Watch. (Image credits: https://sites.google.com/a/globalsystemsscience.org/digital-earth-watch/key-messages/near-infrared-and-the-electromagnetic-spectrum)

Subscribe to the Felix instruments Weekly article series.

By submitting this form, you are consenting to receive marketing emails from: . You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact

Light is made up of wavelengths. The visible range that the human eye can see (VIS; 400–700 nm) is only a small part of it; see Figure 1. To sort and control food quality, many parts of the infrared range are also used, including the near-infrared range (NIR; 700–1400 nm) and short wave infrared (SWIR; 1400–3000 nm).

Initially, spectroscopy based on the visible range was used for in-line sorting units, especially to estimate the color of fruits, as several of the pigments react to light in the visible range.

The infrared spectrum was used by biochemists to test organic compounds, and they were able to show images and characteristics that were not recorded by visible spectrum camera.

The advantage of using the NIR range is that this spectrum’s absorption is associated with the vibration of hydrogen bonds formed with other elements. Hence, they are suitable to identify and quantify biocompounds.

The NIR wavelengths are useful not only for prepared samples, but also for intact products because they can travel into the substances up to a few millimeters to centimeters deep; whereas, wavelengths over 2500 nm have an effective pathway of only micrometers. Since most of SWIR is within this range, they also have longer pathways into intact produce.

NIRs can be used in combination with the VIS or SWIR spectrum. SWIR spectrometers are as good as or more precise than VIS-NIR, but they are far more expensive and give fewer data points. So, VIS-NIR spectrometers are the preferred option.

Challenges in Spectroscopy Monitoring In-line

Though spectroscopy and chemometrics have been worked out for a wide range of parameters, some issues remain that have to be fixed. Some factors that have to be considered in the use of in-line spectroscopy tools are as follows:

- The speed of the conveyor belt. Sampling position is critical, so too much movement can negatively affect results.

- Changes in fruit sizes and shapes being measured.

- Measurement of a representative part of the fruits, keeping in mind the distribution of biocompounds within a fruit. Compounds are not homogeneously distributed in different types and these differences will have to be factored in.

- In-line systems require more calibration and are more complex to operate than their portable counterparts.

Parameters Tested in Packing Houses

The combination of chemometrics and NIR spectroscopy is used to determine the quality and quantity of many internal parameters, such as total soluble sugars, dry matter, characteristic carotenoids, acidity, internal color, internal defects like browning, bruising, rots, stone cracking, and bitter pits. These parameters are widely used to fix harvest time and monitor quality throughout the supply chain.

However, all of them are not used during in-line sorting.

The parameters that are used for in-line commercial sorting are TSS, dry matter, internal defects, acids, and color.

Total Soluble Solids

The first commercial in-line tools sorted fruits according to total soluble solids (TSS). TSS remains one of the most widely used quality parameters for fruits, especially thin-skinned varieties. It is popular because it is an indicator of eating quality, as the TSS level rises as fruits and vegetables ripen.

The fresh produce where TSS can be reliably used in the decreasing order of accuracy are apple, stonefruit, mandarin, banana, melon, onion, tomato, and papaya.

Dry Matter

These days, dry matter estimation is also gaining importance. Many supply chains are setting specifications for dry matter content at harvest time that are measured by NIR spectroscopy tools. In many cases, dry matter content at harvest is the best indicator of fully mature or ripened fruits; it is also a good predictor of final taste and eating quality of fruits. Usually, the aim is to maximize dry matter content so that packing houses can ensure their produce also meet these specifications.

Internal Defects

According to Walsh et al. 2020, the detection of internal defects is the third most popular use of NIR spectroscopy during sorting. Changes in water core, internal composition, browning, frost damage, and moldy cores can be successfully detected by NIRS.

Titrable Acidity

This parameter has varying importance. Titrable Acidity is being factored to estimate taste, as sweetness alone is not enough. However, fruits such as peaches, grapes, etc. will have a lower amount of citric acid equivalent than sour fruits, such as limes.

Internal color

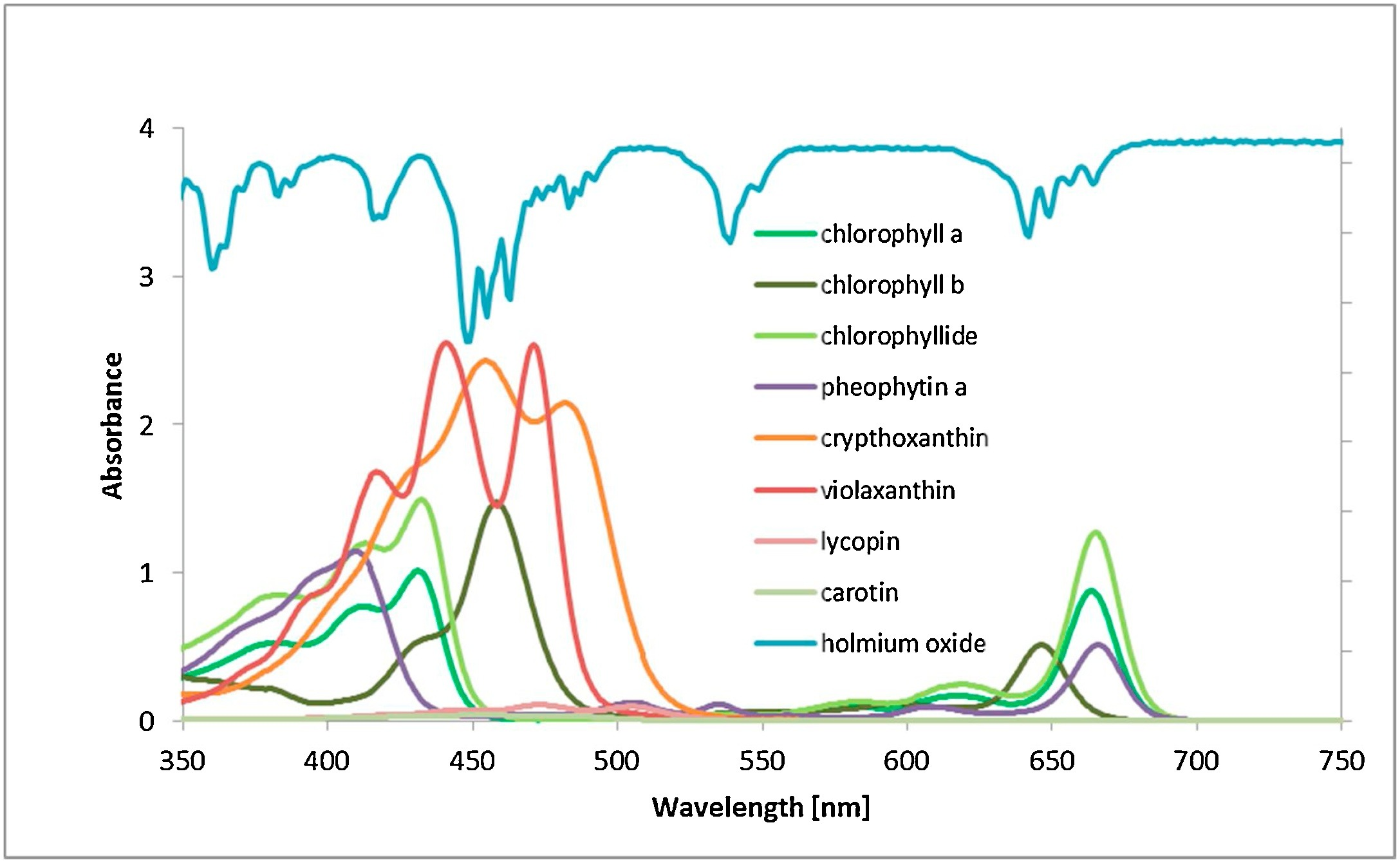

NIRS is good for color analysis and can provide objective measures of external and internal color; see Figure 2.

Figure 2: “Fig. 1. Absorption spectra of pigments,” Walsh et al. 2020. (Image credits: https://www.sciencedirect.com/science/article/pii/S0925521419303230)

Basis for Sorting

NIR and VIS spectroscopy for in-line sorting have been available for nearly three decades.

A combination of TSS, dry matter, levels of organic acids, and skin characteristics will change the spectra within a fruit type. These parameters can be tested in-line to predict and sort fruits based on the difference in the following areas:

- Harvest dates, which indicate different stages of ripening in produce that effect storage time.

- Cultivars, since they can differ in taste and value.

- Health and stress, which can cause internal damage and influence storage time.

Often, a single NIRS tool can be used to detect more than one parameter. It is not possible to reliably estimate firmness with VIS-NIR spectroscopy.

Several sensors and probes are used in packing lines. The in-line quality assessment uses point measurement against area measurement for analysis.

Produce is checked and sorted in post-harvest at varying stages. Sorting is necessary not just for produce meant to be eaten as fresh fruit or vegetables, but also those meant for processing. For example, selecting the right grapes to make wine. If in-line monitoring is too expensive, portable tools can be used in other stages of the supply chain, where sorting is done by the farmers, retailers, or transporters to cull spoiled commodities.

In-line and Other Spectrometers

Earlier VIS-NIR spectrometers were large and room-sized, but the hardware is steadily being miniaturized. With technological advances, these spectrometers were reduced to benchtop equipment, then to small palm-sized devices that can be attached easily to any part of a sorting line.

State of the art commercial spectroscopic systems can monitor fruits on a conveyor with a speed of one meter per second. They can simultaneously control multiple lanes and sort around 10 fruits per second. These systems use SWNIR spectrophotometers.

The in-line VIS-NIR tools have led to the development of small but equally powerful portable devices. For two decades now, the technology that was initially restricted post-harvest to commercial packing houses can now be used throughout the supply chain, even by small suppliers, transporters, and retailers.

A line of portable produce quality meters from Felix Instruments – Applied Food Science is based on NIR spectroscopy and can measure TSS, dry matter, titrable acidity, and external and internal color. Individual readings require only 4-5 seconds and are precise and non-destructive. The following devices can be used in sorting fresh produce in any part of the supply chain:

- F-750 Produce Quality Meter: a customizable device suitable for many fruits and vegetables using model building.

- F-751-Avo Avocado Quality Meter: customized for avocados

- F-751-Mango Quality Meter: with models for common cultivars

- F-751-Kiwi Quality Meter: specially made for kiwis

The last three are based on the F-750 and customized for specific fruits. All four tools are also useful to estimate harvest time on farms.

Cost is Dropping

In-line VIS-NIR or SWIR-NIR systems have been in use for a long time. Developing technology increases the range of parameters they measure by fixing the issues currently holding back their wide adoption. These continuous advances are also likely to make the devices cheaper and easier to use, benefitting the stakeholders and food production in general.

—

Vijayalaxmi Kinhal

Science Writer, CID Bio-Science

Ph.D. Ecology and Environmental Science, B.Sc Agriculture

Feature image courtesy of Liz West

Sources

Dixit, Y., Casado-Gavalda, M. P., Cama-Moncunill, R., Cama-Moncunill, X., Markiewicz-Keszycka, M., Cullen, P. J., & Sullivan, C. (2017). Developments and Challenges in Online NIR Spectroscopy for Meat Processing. Comprehensive Reviews in Food Science and Food Safety, 16(6), 1172-1187. doi:10.1111/1541-4337.12295

Schmilovitch, Z. (2018). Inline Application of NIR System in Produce Sorting Machines. Open Access Journal of Agricultural Research, 3(2). doi:10.23880/oajar-16000155

Walsh, K., Golic, M., & Greensill, C. (2004). Sorting of Fruit Using near Infrared Spectroscopy: Application to a Range of Fruit and Vegetables for Soluble Solids and Dry Matter Content. Journal of Near Infrared Spectroscopy, 12(3), 141-148. doi:10.1255/jnirs.419

Walsh, K. B., Blasco, J., Zude-Sasse, M., & Sun, X. (2020). Visible-NIR ‘point’ spectroscopy in postharvest fruit and vegetable assessment: The science behind three decades of commercial use. Postharvest Biology and Technology, 168, 111246. doi:10.1016/j.postharvbio.2020.111246

Related Products

- F-751 Grape Quality Meter

- Custom Model Building

- F-910 AccuStore

- F-751 Melon Quality Meter

- F-751 Kiwifruit Quality Meter

- F-750 Produce Quality Meter

- F-751 Avocado Quality Meter

- F-751 Mango Quality Meter

- F-900 Portable Ethylene Analyzer

- F-950 Three Gas Analyzer

- F-920 Check It! Gas Analyzer

- F-960 Ripen It! Gas Analyzer

- F-940 Store It! Gas Analyzer

Most Popular Articles

- Spectrophotometry in 2023

- The Importance of Food Quality Testing

- NIR Applications in Agriculture – Everything…

- The 5 Most Important Parameters in Produce Quality Control

- Melon Fruit: Quality, Production & Physiology

- Fruit Respiration Impact on Fruit Quality

- Guide to Fresh Fruit Quality Control

- Liquid Spectrophotometry & Food Industry Applications

- Ethylene (C2H4) – Ripening, Crops & Agriculture

- Active Packaging: What it is and why it’s important