September 27, 2019 at 12:23 am | Updated January 28, 2023 at 4:11 am | 6 min read

Post-harvest fruit ripening is a complicated process. It can produce fruits that don’t just look good but are also tasty and nutritional. Ripening rooms are even more misunderstood than the process itself. Cold storage rooms are not the right places for ripening, and, while fruits will ripen on their own, a ripening room can produce the desired taste and appearance as needed, bringing customers back again for more. Understanding ripening rooms and the ripening process can give suppliers an edge over their competition, improving profits.

What are Ripening Rooms?

Ripening rooms are facilities used to ripen fruits. Modern facilities are designed so that specific environmental conditions can be modified and fine-tuned to control the ripening process. It is possible to produce fruits with a specified ripeness and standardised taste to ensure consumer satisfaction.

There are several systems used around the world, depending on climate and fruit types. Transport ripening facilities are also currently available.

Subscribe to the Felix instruments Weekly article series.

By submitting this form, you are consenting to receive marketing emails from: . You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact

However, the principle of ripening rooms remains the same: use ethylene, a natural hormone at warmer temperatures, to ripen fruits without impacting later storage time.

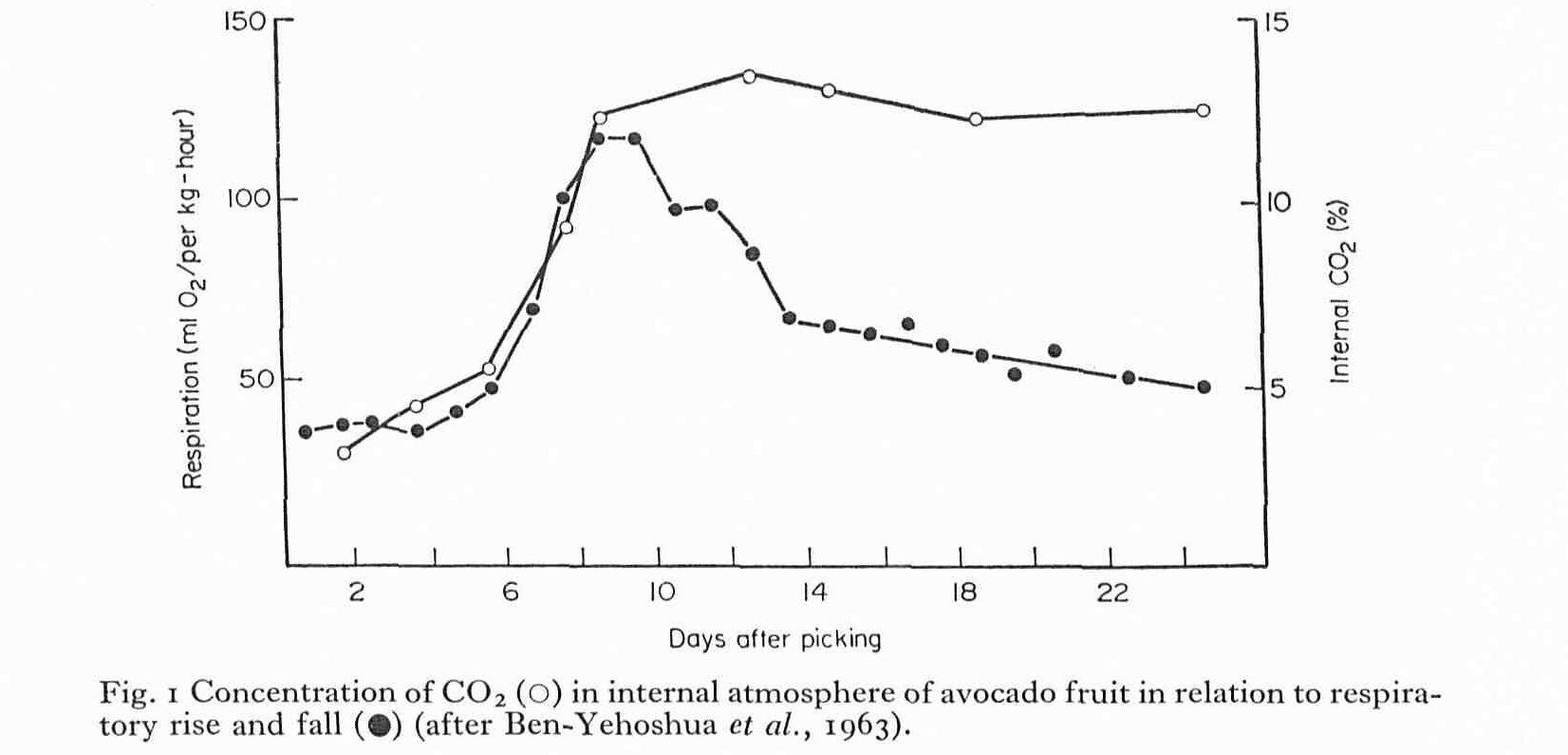

Figure 1. Image credits: Zeroni and Shalom (1973) doi/pdf/10.1111/j.1469-8137.1973.tb02089.x

Optimum Environmental Conditions

There are variations in the conditions that influence ripening in different fruits; however, the parameters remain the same. The important conditions that are regulated in ripening rooms are as follows:

Temperature – Ripening occurs faster at higher temperatures and slows down at low temperatures.

Relative humidity – The best level will vary with the species. However, it will lie within a range of 85-95%.

Supply of ethylene gas – It is advisable to keep ethylene levels below 100 ppm for ripening all fruits and at 3-5 ppm for degreening citrus fruits. There are various sources of ethylene, such as generators, gas cylinders, and lecture bottles. Staff should be trained in the use of the equipment to avoid risks.

Carbon dioxide (CO2) – Carbon dioxide, which is produced as a result of respiration, can slow down ripening. Therefore, its levels should be maintained at less than 0.5% by ventilating the room.

Oxygen (O2) – Since fruits need O2 to ripen, it is important to maintain an optimal level during the process. As O2 decreases, CO2 increases, so the right balance of these two gases is necessary (See Figure 1).

Procedures

Three procedures that are important during ripening are air circulation, ventilation, and monitoring:

- Air Circulation – It is important to ensure that ethylene spreads evenly in the room. Stacking and positioning of packages are an important means to control air flow.

- Ventilation – It is necessary to control the levels of CO2 and ethylene. Ventilation has to take place several times to remove CO2 to maintain the speed of the ripening process. Ventilation is also necessary to reduce ethylene and CO2 levels, as they can be deleterious for the health of people. The CO2 concentration of 3-8% can cause headaches and unconsciousness.

- Monitoring – The levels of the three gases, temperature, and relative humidity are vital to ensure proper progression of ripening. These parameters have to be regularly measured on-site to test and maintain ideal conditions for the fruits.

Duration

Another aspect of ripening that determines the success of the operations is the length of time that fruits are treated. In some cases, the ripening is split into various stages where the conditions provided can be different. Duration depends not only on the species but also its

- Dry matter content (DM) – When DM is higher, the ripening time is shorter, and conversely, more time is needed when fruits have less DM.

- Maturity stage of the fruit – Mature fruits need less time to ripen than immature fruits in the same environmental conditions.

- Temperature – Temperature is adjusted based on maturity and DM. The desired temperature should be reached in the room before the ethylene is supplied.

For example, in the case of avocados ripened with ethylene,

Less mature fruits with DM <26% need 18-200C for 2-3 days.

Mature avocados with DM > 26% need lower temperatures of 16 -200C for only 1-2 days.

Ripenable Fruits

There are two types of fruits: climacteric and non-climacteric. Ripening rooms are not suitable for all of them.

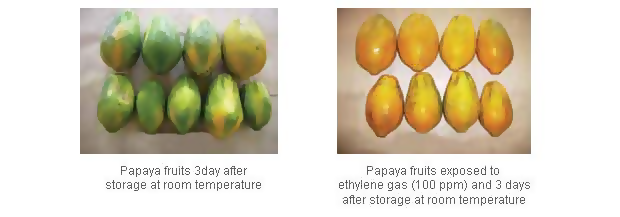

Climacteric: These fruits can be harvested when they are mature and ripened later. They ripen due to a spike in ethylene, the ripening hormone. It is, therefore, only this category of fruits that benefit from ripening rooms. Some examples are mango, banana, fig, apricot, apple, pear, plum, sapota, papaya, kiwis, passion fruits, etc. (See Figure 2).

Non-climacteric: Some fruits have to be allowed to ripen on the tree, as the process stops once they are harvested. Moreover, ethylene is not important during the ripening, and these fruits do not respond to its applications. Ripening rooms are, therefore, not useful for non-climacteric fruits. Citrus such as orange, lemon, tangerine, and grapefruit are the only fruits in this category which are held in ripening rooms, but only to degreen their skin colour. Examples of non-climacteric fruits are strawberry, blackberry, raspberry, grapes, pomegranate, watermelon, cherry, litchi, and citrus.

Figure 2. Uniform ripening with ethylene. (Image credits: http://agritech.tnau.ac.in/horticulture/fruit_ripening.pdf)

Post-Ripening Storage

Fruits can be stored for a short time even after ripening. This storage is outside the ripening rooms, and once again, the time of storage will depend on:

- Variety

- Storage temperature

- Level of ripeness

For example, Haas avocados are stored at 5-70C and Shepherd at 6-80C for three to seven days.

Types of Ripening Rooms

There are simple, traditional, and advanced methods of ripening that are used.

- Airtight container – For small-scale ripening, fruits are stored in an airtight container or bag so that the ethylene they produce doesn’t escape and ripening occurs faster.

- Smoke chambers – Fruits are stored in rooms through which smoke is passed to ripen fruits.

- Hay or husk cover – Fruits are laid out in layers and covered with wheat hay or rice husk for a week to help them ripen.

- Modern ripening rooms – There are several modern patented facilities where environmental conditions can be controlled precisely to ensure accurate ripening. Some of them are:

- Lock Sock

- NTH Model

- Side Curtain Type

- Air Bag System

- Tarped Model

Innovations for Ripening

There are several innovations which improve different aspects of ripening. All new technology is aimed at providing a better ripening environment. Some important developments are mentioned below.

Ethylene Supply

Ethylene is the only hormone/compound that is recommended for use in ripening. Precise amounts can be supplied through several techniques:

- Shot injection administers gas periodically every six to eight hours to reach the required level up to 100 ppm.

- Trickle injection supplies ethylene constantly.

- Catalytic generation generates ethylene every six to eight hours to reach up to 100 ppm.

- Controlled monitoring allows the room to be monitored; gas is supplied only as needed to reach up to 100 ppm.

Ventilation Systems

Venting systems control levels of CO2, O2, and ethylene. Since ventilation is a frequent and important practice, several methods are available

- Shot and Catalytic systems require the manual opening of doors every six to eight hours.

- Trickle system continuously releases inside air and lets in the fresh air.

- Controlled monitoring requires ventilation only when CO2 reaches 1%.

Forced Air Ripening systems

These systems control temperatures. Their efficiency depends on the stacking system so that air can move easily within and between pallets.

Instruments for Monitoring

Ripening room such as those fabricated by Dutch-maker Interko (https://interko.com/) and instruments such as the Felix AccuRipe system and hand-held line of gas analyzers can enable users to monitor and control CO2, O2, and ethylene leves in real time. These systems are programmable for any commodity so users can enter their ripening “recipe” and the system does the heavy lifting for them.

Get the Right Systems

It is important to know that systems and combinations of parameters will differ between temperate and tropical countries. There have been cases reported where people have purchased the wrong ripening room system. Knowledge of modern ripening processes is not widespread, so using an expert to choose the correct system is one easy way to avoid costly mistakes. Besides improving profit margins, modern ripening rooms can save fruit waste due to inefficient handling.

—

Vijayalaxmi Kinhal

Science Writer, CID Bio-Science

Ph.D. Ecology and Environmental Science, B.Sc Agriculture

Sources

Fruit ripening rooms. Retrieved from http://nhb.gov.in/schemes/interko.pdf

G.M. Symons, Y.-J. Chua, J.J. Ross, L.J. Quittenden, N.W. Davies, J.B. Reid, Hormonal changes during non-climacteric ripening in strawberry, Journal of Experimental Botany, Volume 63, Issue 13, August 2012, Pages 4741–4750, https://doi.org/10.1093/jxb/ers147

Ledger, S., Barker, L., Hofman, P., Campbell, J., Jones, V., Holmes, R., Campbell, T., & Matthew Weinert, M. (2012). Mango Ripening Manual. Retrieved from https:///C:/Users/Becker/Desktop/Mango+ripening+manual_d4+final.pdf

Moirangthem, K., & Tucker, G. (2018) How Do Fruits Ripen?. Front. Young Minds. 6:16. doi: 10.3389/frym.2018.00016

Queensland Agriculture. (2016, Dec 5). Avocado ripening and storage. A video guide for wholesalers. Retrieved from https://www.youtube.com/watch?v=2vxpu-fuF6M

Science Buddies Staff. (2017, July 28). How Does Packaging Affect the Ripening of Fruit? Retrieved from https://www.sciencebuddies.org/science-fair-projects/project-ideas/MatlSci_p022/materials-science/how-does-packaging-affect-the-ripening-of-fruit

Tamil Nadu Agricultural University. Fruit Ripening. Retrieved from http://agritech.tnau.ac.in/horticulture/fruit_ripening.pdf

Thompson, J. (2015). Ripening Facilities & Equipment. Postharvest Technology Center, UC Davis. Retrieved from https://ucanr.edu/datastoreFiles/234-2813.pdf

Related Products

- F-751 Grape Quality Meter

- Custom Model Building

- F-910 AccuStore

- F-751 Melon Quality Meter

- F-751 Kiwifruit Quality Meter

- F-750 Produce Quality Meter

- F-751 Avocado Quality Meter

- F-751 Mango Quality Meter

- F-900 Portable Ethylene Analyzer

- F-950 Three Gas Analyzer

- F-920 Check It! Gas Analyzer

- F-960 Ripen It! Gas Analyzer

- F-940 Store It! Gas Analyzer

Most Popular Articles

- Spectrophotometry in 2023

- The Importance of Food Quality Testing

- NIR Applications in Agriculture – Everything…

- The 5 Most Important Parameters in Produce Quality Control

- Melon Fruit: Quality, Production & Physiology

- Fruit Respiration Impact on Fruit Quality

- Guide to Fresh Fruit Quality Control

- Liquid Spectrophotometry & Food Industry Applications

- Ethylene (C2H4) – Ripening, Crops & Agriculture

- Active Packaging: What it is and why it’s important