May 14, 2021 at 5:10 am | Updated April 11, 2022 at 6:44 am | 7 min read

Mango varieties are exported around the world for their special flavors. A mango that is not ripe and sweet will not meet consumer expectations, regardless of how exotic the variety is.

Harvesting fruits at the time suitable for each variety is crucial to ensure the final quality. To decide harvest time, maturity indices in portable NIRS tools should ideally be calibrated for specific varieties.

Demand is Hampered by Mango Quality

The hundreds of mango varieties differ in color and taste. The most important varieties that get exported to Europe are fibreless Kent and Keitt. Palmer ranks third, as it has fewer fibers. Mango consumption is rising in Europe, but there is no guaranteed supply. Available volumes, along with mango quality and price, are a few factors that are holding back consumption.

Subscribe to the Felix instruments Weekly article series.

By submitting this form, you are consenting to receive marketing emails from: . You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact

This is also the case with the Palmer mango, a late-season variety whose quality problems are associated mainly with harvesting time.

A few of the bottlenecks to the trade, like mango quality, can be controlled by further research to finetune the effectiveness of established technology.

Testing Mango Maturity

Mango (Mangifera indica) is a climacteric fruit. It can be harvested when it is fully mature and artificially ripened later without loss of quality. This extends its transportation and storage time. Fruits meant for exports must be fully mature. Mangos harvested when immature will not develop the desired taste and quality. When mangos are harvested for the local markets, growers usually allow them to ripen on the tree.

It has always been challenging to find a relevant mango maturity index to fix the harvest time, given the differences in varieties, production, growing methods, and climate.

Shape, size, skin hue, shoulder growth, etc. are variety specific and subjective, and require expertise. Moreover, color is not a reliable maturity index, as fruits tend to be green before ripening.

The color change of flesh and hardening of the endocarp are reliable indicators of ripening, but this mango testing technique requires destructive sampling. Non-destructive methods are preferable to save harvests, as mango testing is done frequently, not only in the farms but also at packing houses. Non-destructively estimating internal chemical quality using near infrared and visible spectroscopy is well established.

Internal chemical parameters, such as soluble sugar content, acidity, carbohydrates, and dry matter, are used as maturity indices in many mango cultivars for mango testing. There are great differences in the sugar content and dry matter of cultivars, so using a device specifically modelled for one variety would give inaccurate predictions of maturity for other varieties.

There are several portable NIRS devices on the market that have maturity indices calibrated for Kent, one of the most internationally popular mango varieties. However, maturity indices are not often found for Palmer mangos.

Moreover, there is no standard mango maturity index that people can apply to estimate maturity in newer varieties of interest, due to the differences that exist in varieties and growing conditions. Hence, it is necessary to develop a novel maturity index for each cultivar.

Agricultural scientists, Santos Neto, Dantas De Assis, Casagrande, Cunha Junior, and Teixeira, endeavored to develop such a model for Palmer mango.

The Experimental Setup

From 300 panicles of mango, the aforementioned scientists harvested 149 mangos when they were in six stages of fruit development:

- 91 days after bloom (DAB)

- 98 DAB

- 105 DAB

- 112 DAB

- 119 DAB

- 126 DAB

Calibration models were made to track DM and SSC changes through these six stages to see when mango maturity was achieved.

To calibrate models for Palmer mango maturity, the agricultural scientists decided to use a portable NIRS tool that was well established in the industry: the F-750 Produce Quality Meter, manufactured by Felix Instruments Applied Food Science. The F-750, which is equipped with a Carl Zeiss MMS-1 NIRS, can collect spectra in the range of 310–1100 nm with a resolution of 8-13 nm using a halogen lamp as a light source.

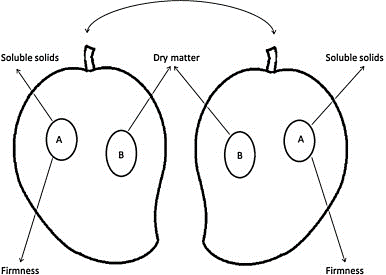

Fig. 1.: “Places where the near infrared (NIR) spectra were acquired and from where the reference analysis were carried out. (A) Soluble solids content (SSC) and firmness, and (B) dry matter content (DM),” Santos Neto et al 2017. (Image credits: https://doi.org/10.1016/j.postharvbio.2017.03.009 )

Figure 1 shows DM and areas of mango testing for SSC and firmness. At portion “A,” SSC and firmness were also measured by a refractometer for comparison. The DM of fruit flesh taken from portion “B” was estimated by the destructive oven-dry method after spectra were collected by the NIRS tool (F-750).

Chemometric Mango Maturity Model

One of the major advantages of using the F-750 is that it has chemometric model building software with easy-to-follow instructions to customize starter models for other varieties.

The correlation of firmness in Palmer mangos to NIR spectra was poor and was, therefore, not used in modeling. The models in the portable NIRS tool were tested only for DM and SSC.

The Partial Least Square Regression (PLSR) model with full cross-validation was used for calibration.

First, the spectra were preprocessed with standard normal variate (SNV) of the first derivative and second derivative of Savitzky–Golay. The spectral wavelengths used were in the range of 699–999 nm.

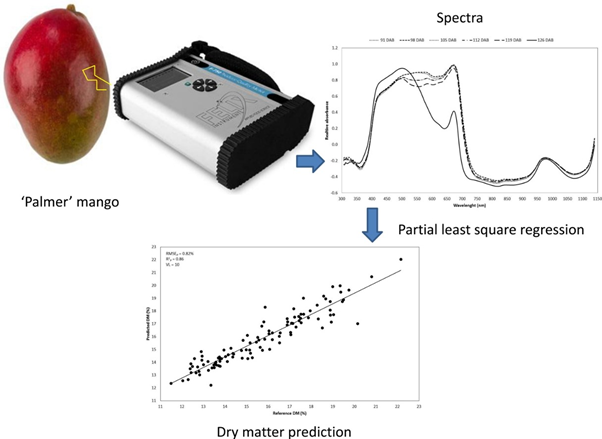

Calibration models used a data set of 272 spectra from 136 fruits. For validation, a data set of 263 spectra was used. Figure 2 shows the various steps in the mango testing procedure. From spectral data collection with the portable NIRS tool, to the final chemometric model selected.

Figure 2: Chemometric modeling of the raw spectra by the Felix Quality Meter F-750 in six fruit stages (91–126 days after bloom – DAB) in Palmer mango gave the best predictions for DM, Santos Neto, et al 2017. (Image credits: https://doi.org/10.1016/j.postharvbio.2017.03.009 )

DM Content is the Best Mango Maturity Parameter

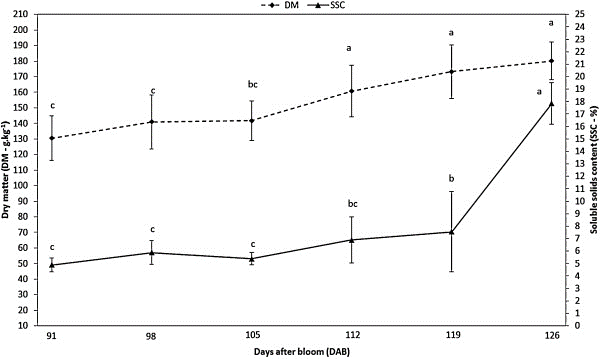

Santos Neto, Dantas de Assis, Casagrande, Cunha Júnior, and Teixeira found that SSC increased in the fruits as they developed, reaching 17.9% at 126 DAB. As shown in Figure 2, the sharpest rise was seen at 112 to 126 DAB, indicating the time when ripening occurs in Palmer mango. During this time, starch is hydrolyzed to sugars.

The DM rose gradually from the onset of fruit development. The most significant changes in DM started at 105 DAB and reached the highest content in 126 DAB. The spurt in DM that marks maturity at 105 DAB happened before ripening starts at 112 days; see Figure 3. Therefore, DM content is a suitable maturity index for Palmer mangos.

The range of DM was 221.2-113.4 g kg−1, and the SSC range was 21.0–3.8%.

The Australian mango industry has established the ideal DM content for mangos as 150 g kg−1. Palmer mangos reach this industry-standard metric on 105 DAB. Using conventional methods, it was found that many growers had been harvesting Palmer mangos at 91 DAB, when the fruits were still immature, which explains the final low eating mango quality at retailers in Europe.

Figure 3: “Dry matter (DM – g kg−1) and soluble solids content (SSC – %) of ‘Palmer’ mangoes harvested at different developmental stages (91–126 days after bloom), reference analysis. The values of each stage are the mean value of 25 fruits (91 DAB), 30 fruits (98 and 105 DAB), 28 fruits (112 DAB), 25 fruits (119 DAB), and 11 fruits (126 DAB). Bars represent the standard deviation (SD),” Santos Neto et al 2017. (Image credits: https://doi.org/10.1016/j.postharvbio.2017.03.009 )

The agricultural scientists found preprocessing with the first derivative of Savitzky–Golay gave the best results. They developed a calibration model for SSC with an RMSECV (root mean square error of cross-validation) of 1.39% SSC and an RCV2 (cross-validation coefficient) of 0.87, with an RPD (Recognition Primed Decision) of 2.77.

The results for DM were better. The calibration model had an RMSECV of 8.81 g kg−1 DM

and an RCV2 of 0.84, with an RPD of 2.51.

The models the agricultural scientists developed were successful, and portable NIRS tools (the F-750, in particular) can be used for Palmer mangos. However, the models are not as robust as those currently in use for other mango varieties. Further testing will increase this robustness.

The variability within trees, orchards, fruit age, and seasons can influence DM evaluations. To improve the prediction of DM and SSC content in Palmer mango by portable NIRS tools, the agricultural scientists would like to incorporate data that covers all these sources of variation to reduce RMSE values. Since these sources of variations are well known, their impact on the prediction powers of the model is not surprising.

Santos Neto, Dantas de Assis, Casagrande, Cunha Júnior, and Teixeira were farsighted in including firmness, a traditional quality parameter. Most current maturity indices focus on SSC and DM alone. By comparing all accepted maturity parameters within a single experiment, they were able to evaluate the best one for non-destructive testing in Palmer mangos. By establishing that predictions of SSC and DM based on spectra are far superior to firmness, field experts should find it easier to convince growers to try the new models.

Advantages of the New Model

The study highlights the need for individual models suited for each mango variety. In 2019, Felix Instruments, brought out the F-751-Mango Mango Quality Meter, with models customized for Tommy K, Ataulfo, Kent, Calypso, Keitt, and Honey Gold. Since the instrument has standardized maturity parameters applicable for many mangos cultivars, it should be easy for scientists to tweak the model to suit other mango varieties. This would increase the efficiency of devices in estimating fruit maturity. The F-750 and F-751 are already in use in many parts of the world to estimate quality and maturity indices in mangos throughout the supply chain. So, we know that the instruments are is useful for a wide range of varieties.

The F-750 is currently in use in many parts of the world to estimate quality and maturity indices in mangos throughout the supply chain. By using a reliable, food industry standard portable NIRS tool, the agricultural scientists will increase the confidence growers and packaging houses will have in the new models and devices.

—

Vijayalaxmi Kinhal

Science Writer, CID Bio-Science

Ph.D. Ecology and Environmental Science, B.Sc Agriculture

Sources

Dos Santos Neto, J. P., De Assis, M. W., Casagrande, I. P., Cunha Júnior, L. C., & De Almeida Teixeira, G. H. (2017). Determination of ‘palmer’ mango maturity indices using portable near infrared (vis-nir) spectrometer. Postharvest Biology and Technology, 130, 75-80. doi:10.1016/j.postharvbio.2017.03.009

Galán Saúco, V. (2015). Current situation and future prospects of worldwide mango production and market. Acta Hortic. 1066, 69-84

DOI: 10.17660/ActaHortic.2015.1066.7

The European market potential for mangoes. (n.d.). Retrieved April 03, 2021, from https://www.cbi.eu/market-information/fresh-fruit-vegetables/mangoes/market-potential

Related Products

- F-751 Grape Quality Meter

- Custom Model Building

- F-910 AccuStore

- F-751 Melon Quality Meter

- F-751 Kiwifruit Quality Meter

- F-750 Produce Quality Meter

- F-751 Avocado Quality Meter

- F-751 Mango Quality Meter

- F-900 Portable Ethylene Analyzer

- F-950 Three Gas Analyzer

- F-920 Check It! Gas Analyzer

- F-960 Ripen It! Gas Analyzer

- F-940 Store It! Gas Analyzer

Most Popular Articles

- Spectrophotometry in 2023

- The Importance of Food Quality Testing

- NIR Applications in Agriculture – Everything…

- The 5 Most Important Parameters in Produce Quality Control

- Melon Fruit: Quality, Production & Physiology

- Fruit Respiration Impact on Fruit Quality

- Guide to Fresh Fruit Quality Control

- Liquid Spectrophotometry & Food Industry Applications

- Ethylene (C2H4) – Ripening, Crops & Agriculture

- Active Packaging: What it is and why it’s important