October 21, 2020 at 9:24 pm | Updated October 21, 2020 at 9:24 pm | 7 min read

With meat consumption steadily increasing each year, long-distance trade and storage in animal products are an essential aspect of the industry. The role of portable Near-Infrared (NIR) spectroscopy in optimizing meat production is not widely known. This technology can single-handedly replace numerous hazardous analytic methods to measure the quality and internal composition of meat at all stages of the supply chain.

Global Meat Production

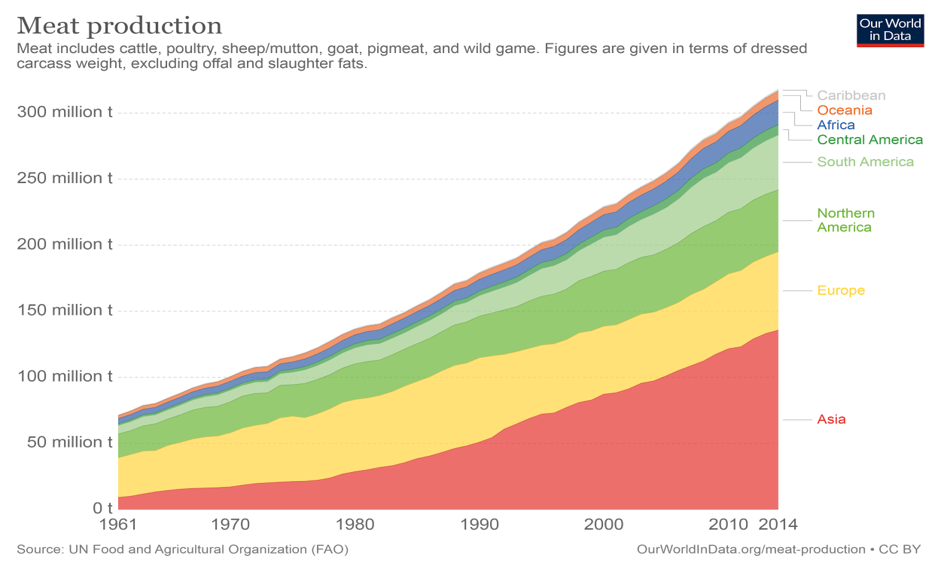

In 2019, the most popular meat eaten was poultry, followed by pork, beef and veal, and lamb. The amount of meat produced globally is vast, extends into millions of metric tonnes (MMT) each year, and continues to rise, as shown in Figure 1. For example, consider the following annual figures for the past few years:

- 128 MMT of poultry

- 121 MMT of pork

- 3.62 MMT of beef and veal

Subscribe to the Felix instruments Weekly article series.

By submitting this form, you are consenting to receive marketing emails from: . You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact

Figure1: Total meat production is increasing worldwide. (Image credits: https://ourworldindata.org/meat-production)

Meat spoils if it is not consumed within a few hours. Not surprisingly, the market for frozen and processed meat products is growing by the year; for example, 30% of beef is frozen. Moreover, many types of meat production are seasonal, so processing is a must. The global frozen meat market, which was worth 73.3 billion USD in 2018, is expected to grow at an annual rate of 4.4% from 2019 to 2025.

With the vast amounts of meat produced and exported, there is a need to monitor quality and chemical composition at various stages of the supply chain.

Portable Near-Infrared (NIR) spectroscopy that makes rapid and non-destructive measurements is the ideal tool for the industry.

NIR Spectroscopy

Of all the wavelengths that make up light, the near-infrared spectrum is most suitable for measuring the internal composition of animals. The NIR spectrum is absorbed, transmitted, and reflected by the bonds between the elements that make up organic compounds. Moreover, NIR penetrates deeper into tissue samples.

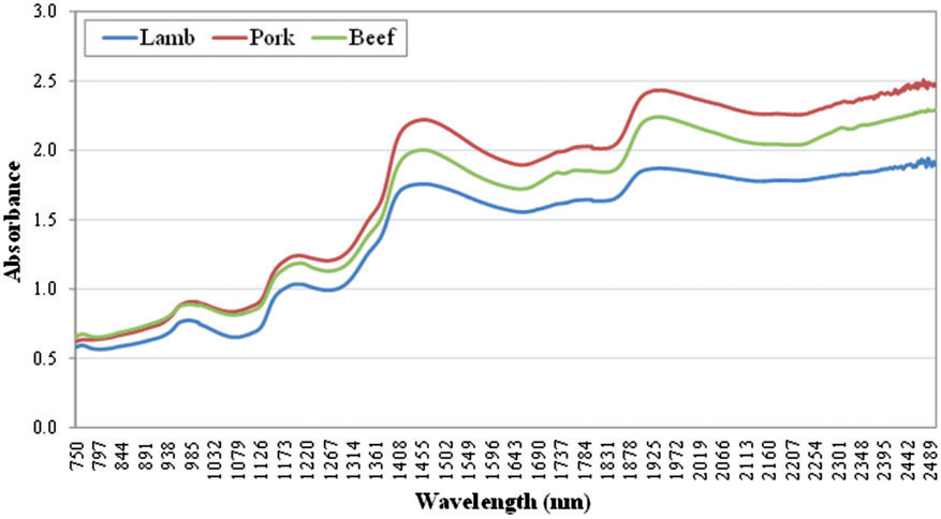

The part of NIR light that is absorbed, transmitted, or reflected is unique to each compound, so NIR can identify and differentiate between compounds. It can also indicate how much of each compound is present in a tissue, as shown in Figure 2.

Since both plants and animals are made of organic compounds, NIR spectroscopy can be used to analyze plant and animal samples. However, it is necessary to use more than one wavelength to detect different compounds in a single meat sample.

Spectroscopy is a complicated technique and it was restricted earlier to large laboratory equipment. Recent technological developments, however, have miniaturized NIR spectroscopy so that it can be fitted into small handheld devices.

This advance in NIR spectroscopy has also reduced the cost of the technique. As a result, the applications of NIR have exploded, as it is now used not just by large institutes and scientists but also by the public. Moreover, it brings the precision and accuracy of this technique to farms, abattoirs, processing factories, storage, and retailers.

One such NIR product is the F-750 Produce Quality Meter produced by Felix Instruments. It can take individual readings within a few seconds and is compact enough to be handled with one hand.

Older Methods of Estimation

Previously, determination of chemical composition had to be done using different procedures for each individual compound. Listed below are a few standard conventional methods:

- Quality and chemical composition were estimated by wet processes.

- Fat quality detection required gas chromatography or solvent-based laboratory methods.

- Protein was measured indirectly by estimating nitrogen by the Kjeldahl method.

- Mineral estimation was a very lengthy process. First, the samples were burnt in a furnace to get ash. Calcium was estimated by an atomic absorption spectrophotometer, and phosphorus was determined by spectrophotometric Molybdovanadphosphate using the ash.

These methods of measuring the chemical composition and quality of meat products are slow, expensive, and require elaborate sample preparation. Moreover, many of them involve the use of chemicals, like concentrated acids, which are an occupational hazard.

A single portable NIR that makes rapid and non-destructive measurements can replace all these old, chemical methods, without producing any hazardous waste.

Application of NIR Spectroscopy

NIR spectroscopy’s application starts after the killing of animals for meat production.

The ability of NIR spectroscopy to measure chemical composition and quality has several applications in animal production. The technique, however, is not equally suitable for each task, and there can be a difference in the performance of spectroscopy.

Figure 2. Near-infrared spectra interaction of meat samples from different species as measured by a portable device. (Image credits:DOI: 10.1177/0003702817709299)

1. Chemical composition

One of the main reasons to use NIR spectroscopy for animal production is to predict the composition of the different components in meat, such as protein, fat, and moisture content. This is crucial, as it can reflect the quality and palatability of the meat and effect on consumer health. All kinds of animal products—fresh, frozen, and processed—can be tested.

- Moisture content is quickly and accurately measured by NIR spectroscopy.

- Protein estimation of intact samples is challenging. Proteins are not distributed in the meat evenly and are present in low amounts. So, several scans of various portions of the samples are necessary in case of intact meat (fresh or frozen) to provide the actual average of proteins. Ground and processed meat that is mixed is easier to test for proteins.

- Fat estimation is crucial for all meat, especially pork. Pigs can accumulate large amounts of unsaturated or soft fat that is unhealthy, impacts flavor, and causes oxidation of meat, which spoils it quickly. In many parts of the world, like the USA and EU, soft fat content is strictly regulated. Pork with higher fatty concentrations fetches lower prices. NIR spectroscopy can easily predict fat content by measuring the iodine value (IV) of subcutaneous fat in fresh, frozen, dried, and processed (sausages) pork.

- Minerals, such as calcium and phosphorus, are essential to determine nutritive value in poultry. Testing intact birds with NIR can quantify these elements accurately.

2. Quality Control

Besides using chemical composition to analyze the quality of meat, two other factors that can influence the appearance of meat are monitored by NIR. These are the pH and water-holding capacity of meat.

- pH estimates by NIR are more accurate in intact meat compared to ground meat. Ground meat products with a mix of proteins and fats give more accurate readings.

- Water-holding capacity measurement is vital to see how meat retains moisture after cooking, thawing, or drying. Direct measurements of water holding capacity are possible for fresh meat. After meat is processed, aged, or cooked, indirect measures based on water, intermuscular fat, and protein content by NIR spectroscopy can be used.

3. Identification of Meat

When products are processed or frozen, it is difficult to identify the meat. NIR spectroscopy can detect and differentiate between the species, breed, geographic area of origin, feeding systems, and even post-mortem methods with an accuracy of 89-100%. For example, NIR can identify horse, llama, and cattle meat and helps in detecting fraudulent products during export, price-fixing, and retailing.

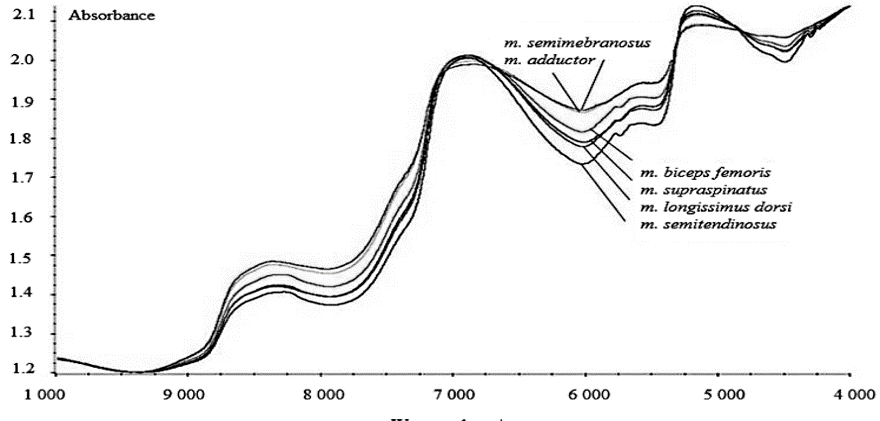

Figure 3: “Example of pork meat spectra.” (Image credits: http://www.maso-international.cz/download/39_43.pdf)

NIR spectroscopy can also identify muscle types using the dry matter, crude protein, and ether extract of samples. Meat samples need to be fresh or thawed from frozen products, see Figure 3.

4. Processing

During the manufacturing of processed products, it is vital to test chemical composition to select meat in order to check the process and end-products.

- Sausage manufacturing requires knowledge of chemical composition to optimize recipes during the production of sausages. NIR has been used to measure proteins, fat, and water of ground meat ingredients.

Post-manufacture, the quality control of sausages cased in plastic is possible, as the casing doesn’t scatter NIR light. So, portable NIR is also useful in the retailing of processed products. - Aging beef improves flavor and texture. Drying makes the meat tender and enhances the taste. During the process, the surface of the beef can attract fermentation micro-organisms depending on moisture levels. So, NIR is used to monitor moisture levels on the surface of the meat.

- Checking for adulterants: Soya is often used as an adulterant with beef, as it is cheaper than the animal product. Many people, especially children, can be allergic to non-meat proteins, so it is crucial to check for soy adulterants during retailing. NIR devices can replace current methods, such as microscopic examination, electrophoretic, or chromatographic techniques. All of these methods are time-consuming, involve a waiting time to get results, and also need destructive sampling.

Multifaceted Technology

NIR spectroscopy is unique in that it measures more than one parameter. By eliminating several expensive processes, it makes quality control affordable. The same NIR spectroscopy tool can be used for many functions in the production of meat products and in many stages. It is surprising that its use is currently limited. However, as awareness of NIR applications in the animal industry grows, we are likely to see an extensive application of this versatile technology.

—

Vijayalaxmi Kinhal

Science Writer, CID Bio-Science

Ph.D. Ecology and Environmental Science, B.Sc Agriculture

Feature image courtesy of Mike Mozart

Sources

Alomar, D., Gallo, C., Castañeda, M., & Fuchslocher, R. (2003). Chemical and discriminant analysis of bovine meat by near infrared reflectance spectroscopy (NIRS). Meat Science, 63(4), 441–450. doi: 10.1016/s0309-1740(02)00101-8

Conway, A. (2019, November 26). World poultry production to top 128 million tons in 2019. Retrieved from https://www.wattagnet.com/articles/38882-world-poultry-production-to-top-128-million-tons-in-2019?v=preview

Frozen Meat Market Size, Share & Trends Analysis Report By Product Type (Beef, Pork, Chicken), By Distribution Channel (Convenience Stores, Supermarket & Hypermarket, Online), And Segment Forecasts, 2019 – 2025. (2019, May). Retrieved from https://www.grandviewresearch.com/industry-analysis/frozen-meat-market

Ishikawa, D., Ueno, G., & Fujii, T. (2017). Estimation Method of Moisture Content at the Meat Surface During Drying Process by NIR Spectroscopy and Its Application for Monitoring of Water Activity. Japan Journal of Food Engineering, 18(3), 135–143. doi: 10.11301/jsfe.17493

Jiang, H., Zhuang, H., Sohn, M., & Wang, W. (2017). Measurement of Soy Contents in Ground Beef Using Near-Infrared Spectroscopy. Applied Sciences, 7(1), 97. doi: 10.3390/app7010097

Kadim, I. T., Mahgoub, O., Al-Marzooqi, W., & Annamalai, K. (2005). Prediction of Crude Protein, Extractable Fat, Calcium and Phosphorus Contents of Broiler Chicken Carcasses Using Near-infrared Reflectance Spectroscopy. Asian-Australasian Journal of Animal Sciences, 18(7), 1036–1040. doi: 10.5713/ajas.2005.1036

Králová, M., Procházková, Z., Saláková, A., Kameník, J., & Vorlová, L. (n.d.) Determination of meat quality by near-infrared spectroscopy. Retrieved from http://www.maso-international.cz/download/39_43.pdf

Lee, G.-H. D. (1984). Rapid determination of selected meat components using near infrared reflectance spectroscopy (dissertation), Iowa State University.

Mlček, J., Šustová, K., & Simeonovová, J. (2011). Application of FT NIR spectroscopy in the determination of basic chemical composition of pork and beef. Czech Journal of Animal Science, 51(No. 8), 361–368. doi: 10.17221/3952-cjas

Prieto, N., Roehe, R., Lavín, P., Batten, G., & Andrés, S. (2009). Application of near infrared reflectance spectroscopy to predict meat and meat products quality: A review. Meat Science, 83(2), 175–186. doi: 10.1016/j.meatsci.2009.04.016

Shahbandeh, M. (2019, August 9). Beef and veal export volume worldwide, 2019. Retrieved from https://www.statista.com/statistics/617458/beef-and-veal-export-volume-worldwide-by-country/

Shahbandeh, M. (2019, August 9). Global pork production by country, 2018. Retrieved from https://www.statista.com/statistics/273232/net-pork-production-worldwide-by-country/

Related Products

- F-751 Grape Quality Meter

- Custom Model Building

- F-910 AccuStore

- F-751 Melon Quality Meter

- F-751 Kiwifruit Quality Meter

- F-750 Produce Quality Meter

- F-751 Avocado Quality Meter

- F-751 Mango Quality Meter

- F-900 Portable Ethylene Analyzer

- F-950 Three Gas Analyzer

- F-920 Check It! Gas Analyzer

- F-960 Ripen It! Gas Analyzer

- F-940 Store It! Gas Analyzer

Most Popular Articles

- Spectrophotometry in 2023

- The Importance of Food Quality Testing

- NIR Applications in Agriculture – Everything…

- The 5 Most Important Parameters in Produce Quality Control

- Melon Fruit: Quality, Production & Physiology

- Fruit Respiration Impact on Fruit Quality

- Guide to Fresh Fruit Quality Control

- Liquid Spectrophotometry & Food Industry Applications

- Ethylene (C2H4) – Ripening, Crops & Agriculture

- Active Packaging: What it is and why it’s important