October 21, 2020 at 9:27 pm | Updated October 21, 2020 at 9:27 pm | 6 min read

Ethylene is a phyto-hormone present in plants. Levels of the hormone that exist normally in storage facilities are high enough to reduce post-harvest time in the case of both climacteric and non-climacteric fruits. It is, therefore, necessary to monitor the levels of ethylene accurately at various points of fresh produce supply chains. Until recently, there were no small instruments available for use in the supply chain. Recent developments of portable devices are revolutionizing food producers’ and suppliers’ ability to maintain post-harvest stock.

What is Ethylene?

Ethylene is present in plants and influences many physiological processes, such as germination, sprouting, root development, stem elongation, leaf and flower abscission, and fruit ripening.

However, not all fruits need ethylene for ripening. During fruit development, the cells in the fruit first increase in number. The fruit cells act as sinks for starches and sugars produced during photosynthesis.

Subscribe to the Felix instruments Weekly article series.

By submitting this form, you are consenting to receive marketing emails from: . You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact

Ethylene Producers

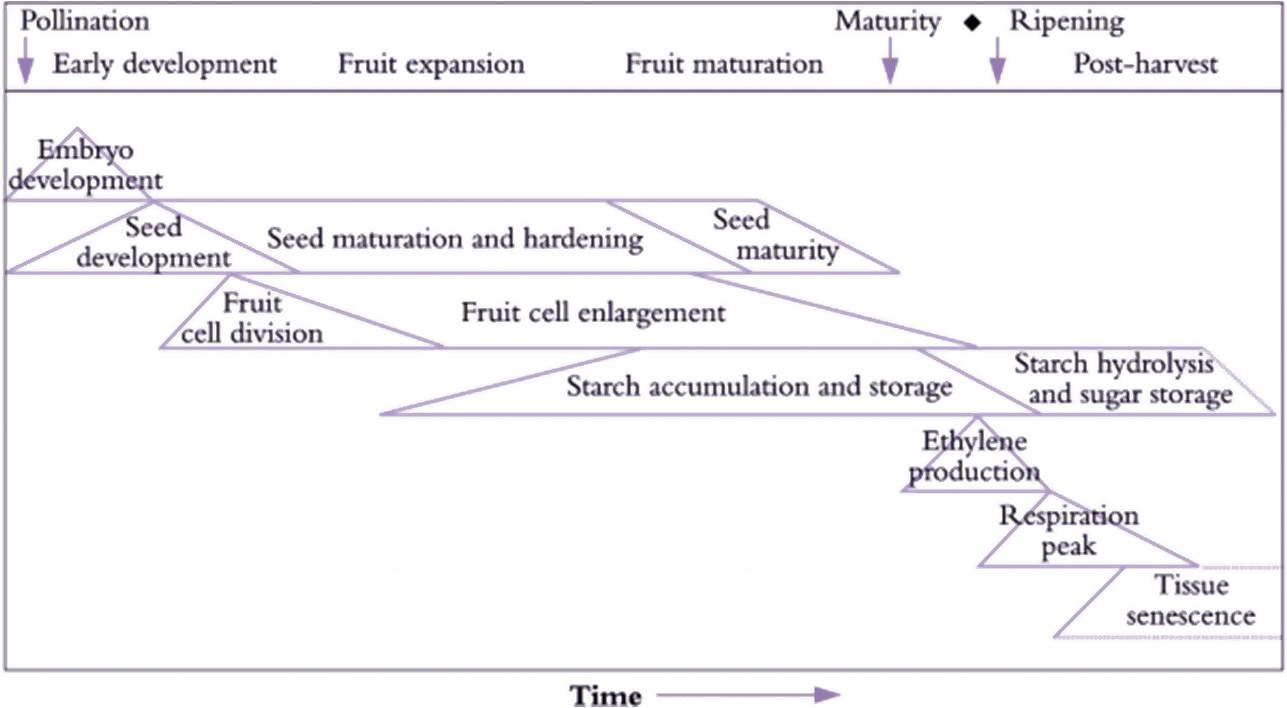

In the case of climacteric fruits, starches are stored during maturation. When this phase is over, ethylene is produced by the fruits. This triggers ripening to change starch to sugars, as part of the ripening stage. Therefore, climacteric fruits are called ethylene producers (See Figure 1).

Figure 1: Fruit development and ripening in climacteric fruits. (Original diagram courtesy I.B. Ferguson).” (Image credits: http://www.asps.org.au/wp-content/uploads/Chapter-11-Fruit-growth-ripening-and-post-harvest-physiology.pdf)

Ripening is associated with changes in texture, flavor, taste, and color of fruits. An increase in respiration also occurs, which leads to breaking down stored sugars.

By controlling the amounts of ethylene in post-harvest, the rate of ripening can be slowed or increased. This feature is used in long distance transport of this group of fruits. They are harvested when they are mature, but still hard and green. This is the ideal condition in which to transport fruits. Later, when they are ripe, they are soft and require more care during handling to avoid damage of fruits.

Various methods are used to prevent or control ethylene levels in fruits. When necessary, the fruits can be ripened later by external application of ethylene so that they are ready for retail.

Some of the common ethylene producing foods, according to the Iowa State University Extension and Outreach, are:

- Apple

- Apricot

- Avocado

- Banana

- Mango

- Cantaloupe

- Pear

- Peach

- Plum

- Potato

- Tomato

Ethylene Sensitive Fruits

In the case of non-climacteric fruits, there is only an accumulation of sugars, even during maturation, and they don’t use ethylene for the ripening process. The hormones that influence ripening are not as well documented, as there isn’t a single hormone that works for this whole group. Hormones, such as auxins, abscisic acid (ABA), gibberellins (GAs), and brassinosteroids (BRs), can be found in different types that ripen the fruits until harvest. After harvest, there is little or no further ripening.

However, since all plants are influenced by ethylene, some non-climacteric fruits will age and rot rapidly due to external application of ethylene. These are called ethylene sensitive fruits.

The non-climacteric and ethylene sensitive crops, according to Iowa State University Extension and Outreach, are:

- Asparagus

- Broccoli

- Brussels sprouts

- Carrots

- Cauliflower

- Cucumbers

- Eggplants

- Green beans

- Kale

- Lettuce and other greens

- Onions

- Parsley

- Peas

- Peppers

- Summer squash

- Sweet potatoes

- Watermelon

Ethylene Post-Harvest

The most important commercial application of ethylene is its role in the fruit ripening process. Ethylene is not toxic to people in the concentrations in which it is used in ripening rooms (100-150 parts by million or ppm).

Regardless of the need for ethylene during ripening, it is important to maintain low ethylene levels to increase post-harvest time for both climacteric and non-climacteric fruits.

In storage areas, it is best to maintain ethylene levels below 0.005 ppm or (<0.005 μL/L), as levels over these can reduce the post-harvest time by ten to thirty percent. The ethylene concentrations of 0.03-0.38 ppm in holds with non-climacteric fruit in storage comes from the ambient atmosphere in the market, either from machinery or due to the presence of climacteric produce in the same storage facility

Ethylene levels of 0.1 – 1.0 ppm can trigger irreversible ripening in climacteric fruits. Storage units of climacteric fruits can have concentrations of 0.014-4.9 ppm in the air.

The levels of ethylene that usually occur are not favorable to extend transport, storage, and marketing time.

Good Ethylene Management Practices

Keeping the effects of ethylene in mind, some good practices are recommended.

Temperature: Temperature influences ethylene action during the ripening process. When the temperature drops, ethylene is slower. So, it is recommended to keep the storage temperature low to inhibit ethylene action.

Ethylene sensitive fruits: Ethylene can escape through cardboard, wood, or concrete walls. Therefore, do not store ethylene sensitive fruits and vegetables with ethylene producers in the same room or close together. If they are stored or displayed together, ethylene sensitive fruits and vegetables will spoil and reduce profits.

Machinery: Fossil fuels, such as propane, diesel, and gasoline, produce ethylene when they are used to run machinery; protect ethylene sensitive fruits from them.

Removal or reduction of ethylene: Levels of ethylene should be reduced by regular ventilation, and potassium permanganate or commercial scrubbers should be used to oxidize ethylene. Scrubbers are expensive, but they can prevent up to twenty-five percent of lettuce or kiwi loss due to ethylene and can still be profitable.

Uniform ripening: Climacteric fruits can be ripened uniformly by using external ethylene under proper environmental conditions and good circulation of the hormone. According to FAO,

- Good ventilation prevents the accumulation of oxygen that interferes with ethylene action.

- Humidity should be high, around 90 to 95 percent.

- Ideal temperatures are 18°C to 25 °C (65 °C to 77 °F).

- Ethylene levels should be between 10-100 ppm.

In these conditions, fruits need one to three days to ripen, depending on the species and variety.

Portable Devices

Since the reduction of ethylene can rescue a quarter of fresh produce, it is worthwhile for producers, suppliers, and supermarkets to have an ethylene detection device. Currently, three technologies are used in mobile tools due to size, accuracy, and economic considerations. They are:

- Miniature gas chromatography with a column (μ-column) and the pre-concentrator (μPC), with current detection levels of 50 parts per billion (ppb). In some models being developed, there is a tendency of the μPC to get overheated.

- Non-dispersive infra-red Spectroscopy needs the IR band around 10.6 μm. A research study determined that current models are cost effective, but not sensitive enough; lower limits of detection are 20,000 ppb or 20 ppm.

- Electrochemical devices have one of the best resolutions, with lower limits of 10 ppb. The scientists concluded that these devices were the most sensitive to ethylene levels, especially for measuring climacteric fruits.

Felix Instruments have many models that use electrochemical sensors for non-destructive detection of ethylene. They are:

- The F-900 Portable Ethylene Analyzer measures ethylene in real time with measuring intervals of only one second. It is useful for controlled atmosphere facilities, cold storage, and marine containers. It has a lower detection limit of 0.025 ppm and measures up to 200 ppm.

- The F-901 AccuStore & AccuRipe are fixed instruments to monitor and control the flow of ethylene in storage rooms. They maintain low gas levels during storage and can provide uniform ripening. AccuStore has a measurement range of 0-10,000 ppb. AccuRipe can be used for ripening and degreening citrus and has a range from 0-1000 ppm.

- The F- 940 Store It! Gas Analyzer is a handy portable device for use in store rooms and supermarkets. Its ethylene measuring range is 0-10 ppm and recording time is 30 seconds. The two measurement modes are continuous, which allows you to continously measure the ethylene in an area, and trigger, which allows you to only measure when you actively push the button. It has a data logger that can store thousands of readings that can be transferred by USB.

- The F-950 Three Gas Analyzer is a small, portable instrument that simultaneously displays recordings of ethylene, oxygen, and carbon dioxide. The range for ethylene is 0-200 ppm, so it is optimum for controlled environments, packing houses, distribution centers, and modified atmosphere packaging quality control.

- The F-960 Three Gas Analyzer also simultaneously provides readings of ethylene, oxygen, and carbon dioxide. It gives readings in 30 seconds and can be used in dimly lit rooms. It has a data logger with USB transfer. Ethylene measuring range is 0-1000 ppm.

All of the above devices also measure oxygen and carbon dioxide, making them important for maintaining fruit quality and for ripening processes.

A Device for Each Need

The various devices that Felix has produced to monitor ethylene gas are customized for different functions. The instruments meant for storage facilities are more sensitive and can detect lower limits of ethylene, but the range is narrow. The instruments meant for ripening measure a broader range of ethylene gas and can accommodate requirements of several fruits. By filling a lacuna that existed for simple-to-use, portable devices that are also sensitive, these gas analyzers are providing a much needed tool for use in the entire supply chain. They can cut fresh produce loss, extend transport distances and storage time, and improve profits.

—

Vijayalaxmi Kinhal

Science Writer, CID Bio-Science

Ph.D. Ecology and Environmental Science, B.Sc Agriculture

Featured blog image courtesy of

Source

Atkinson, R. G., Brummell, D. A., Burdon, J. N., Patterson, K. J., & Schaffer R. J. (2015). Chapter 11 – Fruit growth, ripening and post-harvest physiology. In B. Atwell, P. Kriedemann & C. Turnbull (Eds.), Plants in Action. Retrieved from http://www.asps.org.au/wp-content/uploads/

Chapter-11-Fruit-growth-ripening-and-post-harvest-physiology.pdf

Cristescu, S. M., Mandon, J., Arslanov, D., De Pessemier, J., Hermans, C., & Harren, F.J.M. (2013). Current methods for detecting ethylene in plants. Annals of Botany, 111:347–360, https://doi.org/10.1093/aob/mcs259

FAO. 5. Post-harvest Treatments Designed to Manipulate the Environment around Produce in Order to Enhance Quality. Retrieved from http://www.fao.org/3/y5431e/y5431e06.htm

Gwanpua, S.G., Jabbar, A., Tongonya, J. et al. (2018). Measuring ethylene in postharvest biology research using the laser-based ETD-300 ethylene detector. Plant Methods 14, 105. doi:10.1186/s13007-018-0372-x

Iowa State University. (2016, July). Store Fresh Garden Produce Properly. Retrieved from https://www.extension.iastate.edu/smallfarms/store-fresh-garden-produce-properly#

Janssen, S., Schmitt, K., Blanke, M., Bauersfeld, M. L., Wöllenstein, J., & Lang, W. (2014). Ethylene detection in fruit supply chains. Philosophical transactions. Series A, Mathematical, physical, and engineering sciences, 372(2017), 20130311. doi:10.1098/rsta.2013.0311

Symons, G.M., Chua, Y.J., Ross, J.J., Quittenden, L.J., Davies, N.W., & Reid, J.B. (2012). Hormonal changes during non-climacteric ripening in strawberry. Journal of Experimental Botany, 63: 4741–4750, https://doi.org/10.1093/jxb/ers147

Wills, R.B.H., & Warton, M.A. (200). A new rating scale for ehtylene action on postharvest fruit and vegetables. IIF-IIR Conference, Murcia, Spain, 2000. Retrieved from http://biopac.com.au/wp-content/uploads/2018/07/Ethylene-ROM-WILLS-full-version.pdf

Related Products

- Felix Expansion Card

- F-751 Grape Quality Meter

- Custom Model Building

- F-910 AccuStore

- F-751 Melon Quality Meter

- F-751 Kiwifruit Quality Meter

- F-750 Produce Quality Meter

- F-751 Avocado Quality Meter

- F-751 Mango Quality Meter

- F-900 Portable Ethylene Analyzer

- F-950 Three Gas Analyzer

- F-920 Check It! Gas Analyzer

- F-960 Ripen It! Gas Analyzer

- F-940 Store It! Gas Analyzer

Most Popular Articles

- Spectrophotometry in 2023

- The Importance of Food Quality Testing

- NIR Applications in Agriculture – Everything…

- The 5 Most Important Parameters in Produce Quality Control

- Melon Fruit: Quality, Production & Physiology

- Fruit Respiration Impact on Fruit Quality

- Guide to Fresh Fruit Quality Control

- Liquid Spectrophotometry & Food Industry Applications

- Ethylene (C2H4) – Ripening, Crops & Agriculture

- Active Packaging: What it is and why it’s important