October 26, 2021 at 11:32 pm | Updated April 11, 2022 at 6:44 am | 8 min read

Many of the nutritional benefits of food are inexorably connected to freshness. Hence, the focus of packaging is evolving from simply extending shelf life to also preserving food quality. This becomes more important when food is not processed, but is sold fresh. Modified Atmosphere Packaging (MAP) can slow the processes that cause deterioration of food quality. Therefore, MAP sales are growing and reached $6.4 billion in 2020. Sales are expected to grow even higher in the 2021-2027 period.

Definition of Headspace and MAP

When you buy a sealed product, there is some empty space within that package, called headspace. Ordinarily, the residual headspace atmosphere contains oxygen (O2), carbon dioxide (CO2), and nitrogen (N2) in proportions different from the natural atmosphere outside in an effort to preserve products. This is called Modified Atmosphere Packaging (MAP).

Both the volume and composition of gasses can be vital in MAP applications. Understanding the specific MAP requirements of each food item is necessary to design and choose packaging materials. For that, a consideration of all factors that affect MAP is also essential.

Subscribe to the Felix instruments Weekly article series.

By submitting this form, you are consenting to receive marketing emails from: . You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact

Factors Affecting Headspace and MAP

Headspace atmosphere is dynamic and can vary due to many factors.

Packaging: The main factor affecting headspace and MAP is the permeability of packaging material. Even plastic polymers are permeable. However, diffusion rates vary, and polymers allow 3-7 times more diffusion of CO2 than O2. The movement of CO2 out of the package is one of the biggest challenges in maintaining MAP. When O2 levels inside headspace decrease, O2 from the atmosphere has been known to diffuse into the package as well.

The ratio of product to headspace: The amount of headspace can also influence product quality, especially for meat products. For pork and beef, the gas headspace to meat ratio should not drop below 2:3; otherwise, the quality is affected. A higher headspace makes no difference with beef, but it harms pork; therefore, package size should not be too large.

Solubility of gas: Gasses will combine and dissolve into packaged food, leading to a decrease in volume. This is a major issue in the case of muscle food, especially fish.

Respiration rate: Fresh produce continue to respire, as they are still alive. The rate of respiration depends on the availability of O2. As a result of respiration, the CO2 concentration will increase, and warmth is generated. Moreover, a combination of physiological and external factors can lead to a 10% difference in respiration rates in different batches of the same product.

External temperature: Temperature influences the rate of respiration in fresh produce. Also, temperature directly affects the quality of food and the growth of microbes. Gas transmission by package materials and dissolution of gases also depends on temperature. Even in modified atmosphere packages, a lower temperature is ideal and is controlled during the handling, transport, and storage of products. A steady-state gas concentration is possible only in distinct conditions, especially in the case of respiring products. Fluctuating or higher temperatures cause anaerobic respiration producing undesirable flavors and ethanol.

Relative humidity: Low relative humidity or fluctuations causes moisture loss. Inside the package, there is no way for the water vapor to escape, this can cause condensation and create foggy conditions. If the temperature falls below the dew point, water vapor liquifies encouraging microbial growth.

Light: How products react to light depends on the packaging material, food product, and light quality. In light-saturated conditions, leafy vegetables will photosynthesize, creating further complications. Therefore, green vegetables store best in the dark with high CO2 levels. However,since high CO2 and low O2 can result in anaerobic respiration, this balance is important to monitor. Beef and ham are negatively impacted by light due to the photooxidation of lipids.

Transport time: To calculate the volume of headspace and MAP, the transport distance must be considered to compensate for the loss of gases through permeable packaging and dissolution. It is vital to ensure that there is enough gas and that packages do not arrive deflated, which gives the impression that the product has been compromised.

Given the factors that influence MAP, the modified atmosphere is achieved by active or passive means:

- In active MAP, the desired mix of gases is injected to get the targeted atmosphere immediately during packing.

- In passive MAP, The interaction of the product with packaging and atmosphere is used to reach optimal atmospheric conditions sometime after packing.

Either way, it is still difficult to maintain a targeted MAP of both O2 and CO2. Gas emitters or active components are included in active packaging to maintain or add gas (CO2), vapor, or aroma. These can be embedded in the packaging material or included as sachets, coatings, or sheets. Active components could also be oxygen-scavenging films.

Headspace and MAP Importance for Different Foods

All kinds of perishable items, such as fresh produce, dairy products, seafood, and meat products, benefit from MAP. However, the MAP will differ for each kind of food. Distinct levels of oxygen and carbon dioxide concentrations are prescribed for different foods. High concentrations of CO2 are used as an antimicrobial measure to preserve all food.

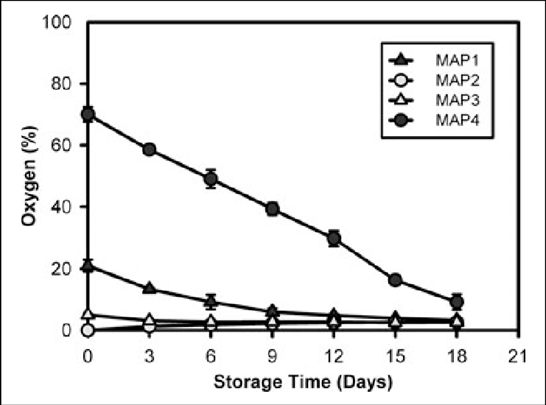

Figure 1: “Effect of modified atmosphere packaging (MAP) on the headspace oxygen concentration (%) during storage of pomegranate arils. (MAP1: 21% O 2 , 79% N 2 ; MAP2: 100% N 2 ; MAP3: 5% O 2 , 10% CO 2 , 85% N 2 ; MAP4: 70% O 2 , 10% CO 2 , 20% N 2,” Ayhan and Esturk (2008). (Image credits: https://www.researchgate.net/publication/260309991_Effects_of_modified_atmosphere_packaging_MAP_on_the_quality_attributes_and_shelf_life_of_ready-to-eat_pomegranate_arils)

Fresh Produce

In fresh produce, many physiological processes continue to occur, as the vegetables or fruits are still living:

- Respiration uses stored materials, so the weight of the product reduces and the quality deteriorates.

- Production of ethylene will eventually lead to ripening, over-ripening, and, in the end, senescence.

- Physical damage and microbial injections also hurt the fresh produce.

In addition, these three physiological processes could be connected. Respiration rate can rise due to the production of ethylene, which in turn is produced during ripening fruits or as a response to physical damage and other stress. As a result, there are changes in color and aroma.

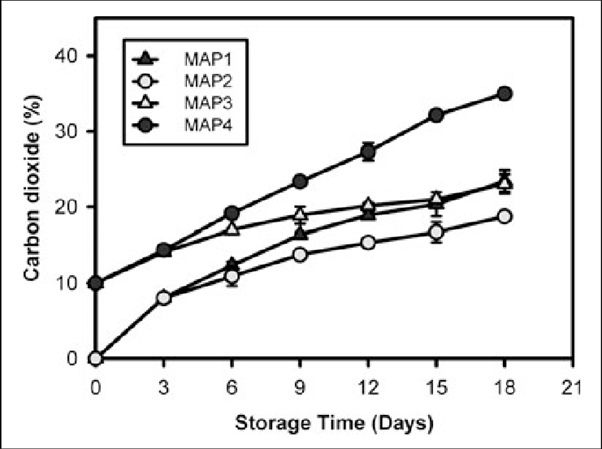

Usually, to reduce respiration rates, oxygen levels in MAP are lower and carbon dioxide levels in MAP are higher than in the atmosphere (Figure 1 and 2). This also controls ethylene and microbial action. However, it may not be possible to control all microbial infections, even under high CO2, as many microbes thrive in anaerobic conditions.

There are also benefits to color and aroma if the CO2 and O2 are used in the correct balance and limits. However, care is taken to ensure that the oxygen level does not drop to create anaerobic conditions, which would lead to fermentation and spoilage.

Figure 2: “Effect of modified atmosphere packaging (MAP) on the headspace carbon dioxide concentration (%) during storage. (MAP1: 21% O 2 , 79% N 2 ; MAP2: 100% N 2 ; MAP3: 5% O 2 , 10% CO 2 , 85% N 2 ; MAP4: 70% O 2 , 10% CO 2 , 20% N 2,”Ayhan and Esturk (2008). (Image credits: https://www.researchgate.net/publication/260309991_Effects_of_modified_atmosphere_packaging_MAP_on_the_quality_attributes_and_shelf_life_of_ready-to-eat_pomegranate_arils)

Meat

MAP with proper headspace allocation can extend shelf life without the addition of chemical food additives.

MAP will interact with package form, meat fat content, external temperature, and microbial flora and loads. The amount of post-mortem water activity and non-proteins will, in turn, determine microbial activity.

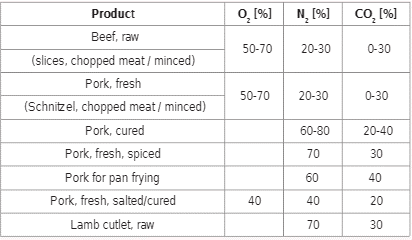

The quality of meat products is determined by their color, water holding capacity, fat composition, and microbial activity. Consumers prefer a red color in meat. Though some oxygen is needed to preserve the red color of the meat, too much oxygen can cause degradative oxidation leading to undesirable brown coloration. O2 levels of 40% for fresh pork and between 50-70% for cut beef and pork are used; see Table 1.

Table 1: “Suitable gas mixtures for storing meat in MAP at temperatures between 1-4 °C,”

Schmid et al. (2016). (Image credits: Austin Food Sci. 2016; 1(1): 1005, https://austinpublishinggroup.com/food-sciences/fulltext/afs-v1-id1005.php)

Carbon monoxide (CO) is added to improve color stability in pork, while the color of beef is maintained by using nitrogen, CO2, and CO, a combination that also controls microbial growth.

By encouraging slow-growing gram-positive microbes, such as lactic acid, and preventing the growth of aerobic gram-negative microbes, shelf life is improved. Hence, CO2 content can range between 10-90%.

MAP has been used to double the shelf life of poultry products. It is used to control microbial activity, so high CO2 levels between 40-100% are used in combination with nitrogen. However, anaerobic bacteria can produce slime and undesirable odors. MAP, with high O2 levels, is better for turkey, as it improves color retention and other sensory parameters.

Seafood

In fish products, quality degradation occurs due to lipid oxidation, microbial spoilage, and enzyme activity. Microbial degradation will affect flavor, texture, and appearance. There are seafood-specific spoilage organisms (SSC) that thrive due to high moisture content, gas composition, and additives like sodium chloride. SSC leads to bad flavors, limited shelf life, and the production of trimethylamine, which causes a fishy smell.

MAP can reduce the growth of SSC to avoid the fishy smell and also limit lipid oxidation. For many types of fish, such as cod, catfish, haddock, herring, salmon, snapper, swordfish, shrimp, and trout, very low levels of O2 and 60-100% of CO2 are used to control microbes.

High levels of carbon dioxide reduce pH by dissolving in fish muscle to form carbonic acid. Often, CO2 emitters are added to fish packaging to maintain proper MAP conditions. However, carbonic acid can denature proteins leading to drip losses. Another risk is botulism by anaerobic bacteria, which can only be solved by keeping MAP packaged fish in cold storage under 3.5oC.

Applications of Headspace and MAP Analysis

The improvement in food supply and quality through MAP, coupled with the challenges posed due to its change in packaging, make headspace and MAP analysis important in both research and industry.

Making MAP recommendations: Research to determine suitable atmospheric conditions and design packaging relies on comparing modified atmosphere in the headspace with various combinations of gases, temperature, relative humidity, and storage length.

Ensuring food quality: There is extensive research being conducted to check on microbial activity in fresh and fresh-cut food in different MAP conditions.

Packaging and Quality Control: In the industry, headspace and MAP analysis are essential during the process of packaging and quality control during transport and storage.

Treatments: Creating ideal MAP conditions in the headspace is not confined only to packaging, but also has applications in post-harvest pre-treatments. It is popular for heat treatment to be used to reduce respiration rates, microbial infection, and chilling damage.

Headspace and MAP Analysis

Both benchtop and portable headspace gas analyzers are in use throughout research and industry applications. The F-920 Check It! Gas Analyzer, manufactured by Felix Instruments – Applied Food Science, is a portable headspace gas analyzer that measures CO2 and O2 levels between 0-100% in seconds. It is a light, handheld device, intuitively designed for heavy use and is battery-driven. It is designed for the food supply chain, but it has also been used for research. The widespread mechanization of processing and packaging has made it easy to integrate MAP to produce consumer-ready packaging in the food industry. MAP obviates the need for chemical treatment and improves the benefits of cold storage by allowing each product to be stored in conditions ideal for them, thereby reducing food loss.

—

Vijayalaxmi Kinhal

Science Writer, CID Bio-Science

Ph.D. Ecology and Environmental Science, B.Sc Agriculture

Sources

Boz, Z., Welt, B.A., Brecht, J.K., Pelletier, W., McLamore, E. (2018). Review of challenges and advances in modification of food package headspace gases,” Journal of Applied Packaging Research, 10 (1). http://scholarworks.rit.edu/japr/vol10/iss1/5

Marcinkowska-Lesiak, M., Poławska, E., Półtorak, A., & Wierzbicka, A. (2017) The effect of varying gas headspace to meat ratio on the quality of pork loin stored in high O2 modified atmosphere, CyTA – Journal of Food, 15:2, 226-233, DOI: 10.1080/19476337.2016.1240237

Murphy, K. M., O’Grady, M. N., & Kerry, J. P. (2013). Effect of varying the gas headspace to meat ratio on the quality and shelf-life of beef steaks packaged in high oxygen modified atmosphere packs. Meat science, 94(4), 447–454. https://doi.org/10.1016/j.meatsci.2013.03.032

Schmid M, Saengerlaub S and Mueller K. Packaging Concepts for Fresh Meat: A Brief Overview. Austin Food Sci. 2016; 1(1): 1005

Sivertsvik, M., Jeksrud, W. K., & Rosnes, J. T. (2002). A review of modified atmosphere packaging of fish and fishery products – significance of microbial growth, activities and safety. Int. J. Food Sci. Technol., 37(2), 107–127.

Tofteskov, J., Tørngren, M.A., Bailey, N.P., & Hansen, J.S. (2019). Modelling headspace dynamics in modified atmosphere packaged meat. Journal of Food Engineering, (248), 46-52, https://doi.org/10.1016/j.jfoodeng.2018.12.013

Related Products

- F-751 Grape Quality Meter

- Custom Model Building

- F-910 AccuStore

- F-751 Melon Quality Meter

- F-751 Kiwifruit Quality Meter

- F-750 Produce Quality Meter

- F-751 Avocado Quality Meter

- F-751 Mango Quality Meter

- F-900 Portable Ethylene Analyzer

- F-950 Three Gas Analyzer

- F-920 Check It! Gas Analyzer

- F-960 Ripen It! Gas Analyzer

- F-940 Store It! Gas Analyzer

Most Popular Articles

- Spectrophotometry in 2023

- The Importance of Food Quality Testing

- NIR Applications in Agriculture – Everything…

- The 5 Most Important Parameters in Produce Quality Control

- Melon Fruit: Quality, Production & Physiology

- Fruit Respiration Impact on Fruit Quality

- Guide to Fresh Fruit Quality Control

- Liquid Spectrophotometry & Food Industry Applications

- Ethylene (C2H4) – Ripening, Crops & Agriculture

- Active Packaging: What it is and why it’s important