October 21, 2020 at 9:26 pm | Updated October 21, 2020 at 9:26 pm | 7 min read

Three main gases have to be monitored in the production of fruits and vegetables: oxygen, carbon dioxide, and ethylene. They are essential in the post-harvest stage and greenhouse production of vegetables and fruits. We discuss the roles of the three gases and some relevant field technologies used in analyzing and controlling their levels.

The Need for GasAnalysis

Levels of all three gases—oxygen, carbon dioxide, and ethylene—have to be maintained at optimum levels in the closed environments present after harvest, during storage, transport, and retailing. Similarly, these gases have to be controlled in greenhouses, where air movement is restricted. An accumulation or depletion of these gases can impact the growing and ripening processes in plants.

The three gases have to be monitored, as they affect vital physiological processes during the development of a plant and fruit. Since the roles of the gases will vary at different stages, we need to learn more about the mechanisms of their action to understand how to control them.

Subscribe to the Felix instruments Weekly article series.

By submitting this form, you are consenting to receive marketing emails from: . You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact

Oxygen

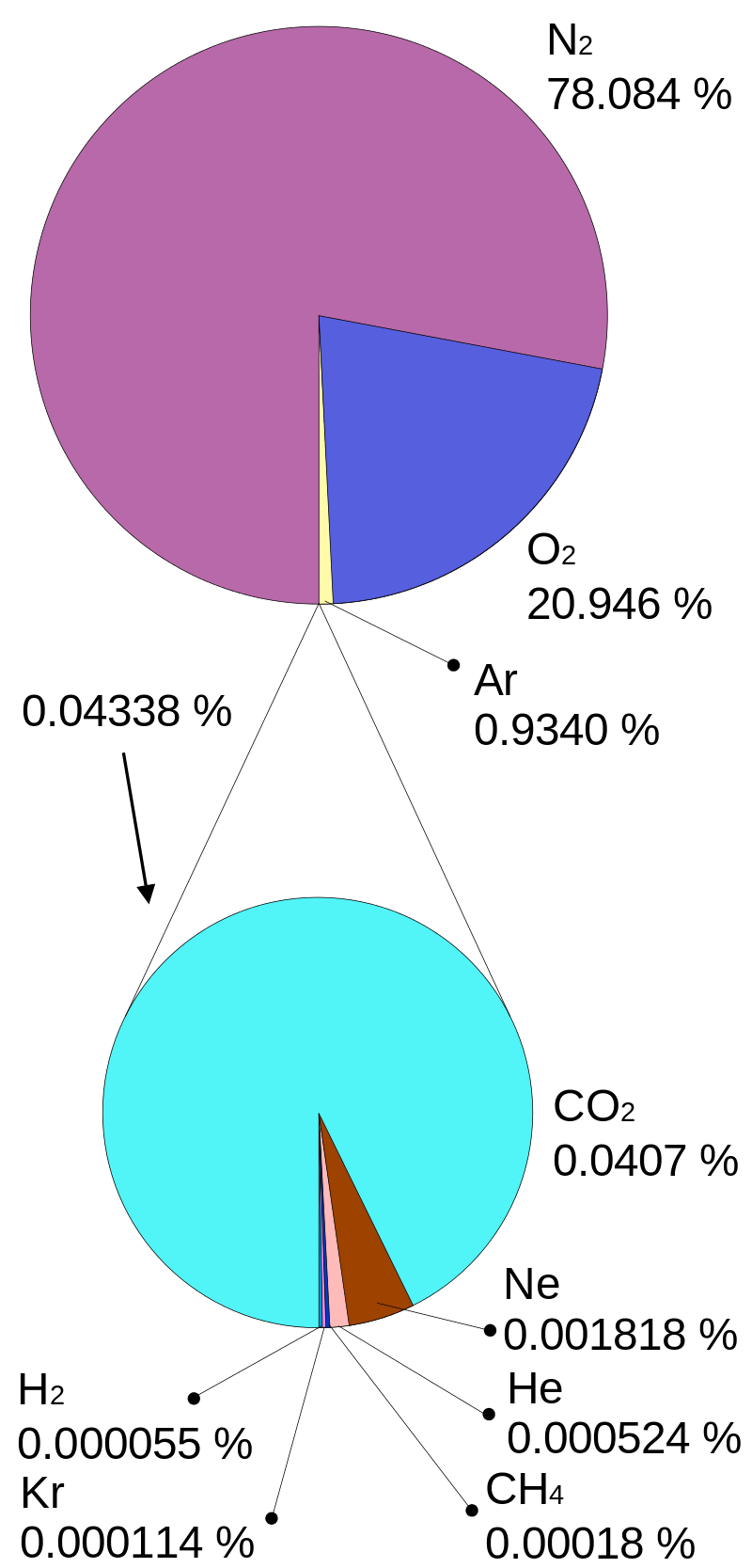

Usually, there is 20% by volume of oxygen in the air (See Figure 1).

Oxygen is essential in every phase of a plant’s life. The whole plant respires, and there is no central organ or tissue that absorbs oxygen. So, oxygen is absorbed by leaves, fruits, and roots from the atmosphere.

In the closed greenhouse environment, rises in temperature are sometimes accompanied by high soil water content. This results in a decrease in oxygen levels in the ground to 2 parts per million by volume (ppm) from 8 ppm, affecting root growth and the overall health of plants.

Fruits continue to respire even after they are harvested. During respiration, oxygen burns glucose to create energy; carbon dioxide and water vapor are produced as by-products.

C6H12O6 + 6 O2 –> 6 CO2 + 6 H2O + energy

Fruits act as sinks and attract glucose produced during photosynthesis; though they use glucose to respire, they keep growing in size. However, once harvested, respiration depletes the glucose reserves, affecting the quality of the fruit. Hence, post-harvest oxygen has to be maintained at low levels. However, a complete absence of oxygen causes anaerobic fermentation resulting in fruit decay.

Oxygen levels of less than five percent are necessary to reduce respiration post-harvest. The rate of respiration depends on the type of fruit and temperature. As temperature increases, respiration in fruits increases. There is also heat produced as a result of respiration that can accumulate in closed spaces.

Figure 1: Amount of different gases in the atmosphere, NASA. (Image credits: https://climate.nasa.gov/news/2915/the-atmosphere-getting-a-handle-on-carbon-dioxide/)

Carbon Dioxide

Photosynthesis is the process by which plants manufacture their food using carbon dioxide and water in the presence of light. For this, carbon dioxide is taken through stomata in the leaves.

In greenhouses, carbon dioxide levels can fall below 200 ppm during the day when photosynthesis occurs. At these levels, carbon dioxide supplementation is necessary to raise the gas levels to 280-340 ppm, either through frequent ventilation or carbon fertilization.

Low levels of carbon dioxide are desirable during post-harvest. Concentrations of carbon dioxide above 1-5% by volume can cause fruit decay, irregular ripening, and the development of bad odors in storage or ripening rooms. If carbon dioxide levels rise above 7% by volume, it prevents the ripening of fruits by decreasing the production of ethylene.

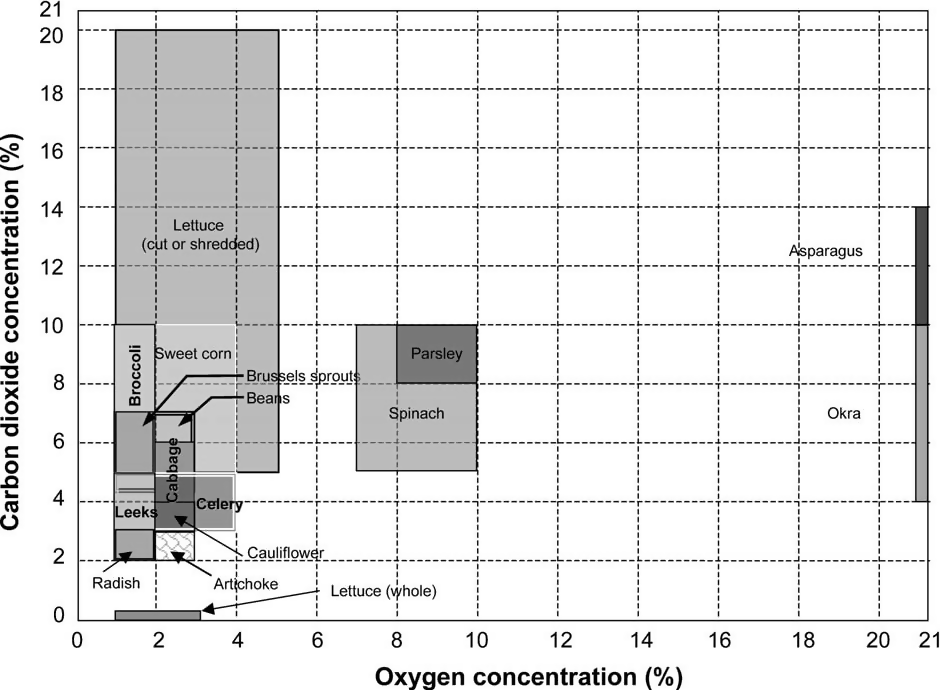

The optimum combination of carbon dioxide and oxygen will depend on the fruit type (see Figure 2).

Moreover, high levels of the gas are unhealthy and can lead to occupational hazards. The effects of very high concentrations of carbon dioxide can range from headaches to unconsciousness and even death. Therefore, levels should be monitored with the utmost care in storage and ripening rooms. The standard carbon dioxide levels in the air are 0.04% by volume.

Figure 2: “Recommended oxygen and carbon dioxide ranges for the storage of some harvested vegetable commodities (Saltveit, 2002).” (Image credits: http://ucce.ucdavis.edu/files/datastore/234-2197.pdf)

Ethylene

Ethylene (C2H4) is a phytohormone produced by plants, and its levels in fruits will vary on many environmental and biotic factors. External factors affecting ethylene production are temperature, levels of oxygen and carbon dioxide, and light duration and intensity. Internally, reactions with hormones and pest or disease attack can alter ethylene concentration in plants.

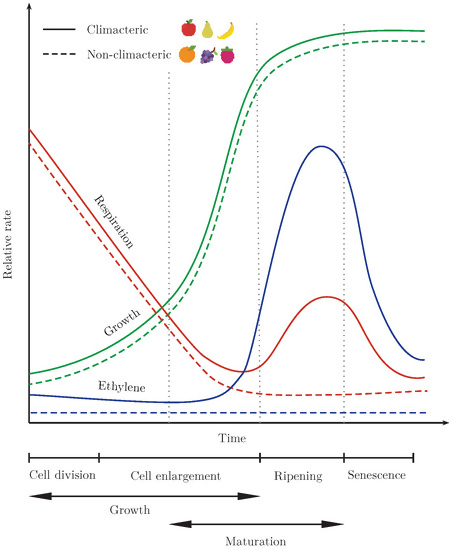

While ethylene has many roles in the life of a plant from germination to senescence/aging, its ripening effect is the most important one for commerce. In climacteric fruits, at the end of maturation, ethylene production rises, inducing ripening. Ripening continues even post-harvest (see Figure 3).

Storage time can be extended by altering environmental factors which depresses the production of ethylene. Low oxygen levels and high concentrations of carbon dioxide reduce ethylene production and prevent the ripening of the fruits. Just 1 ppm of ethylene gas can trigger ripening, so, this gas has to be analyzed precisely.

When necessary, artificial ethylene can be added later to ripen fruits by raising the levels of the gas to around 200 ppm (0.01% to 0.02% by volume in air). The ideal accompanying temperature for ripening is 15-170C.

Figure 3: Respiration and ethylene production in different plant phases in climacteric and non-climacteric fruits, Paul et al. 2011. (Image credits: https://www.mdpi.com/1424-8220/19/2/372/htm#B5-sensors-19-00372)

The latest development in sustainable farming is fitting ethylene sensors on drones. This combination has been tested in apple orchards to measure ethylene levels from a height of six meters to optimize and fix harvest time.

The combination of the three gases recommended will vary at different stages of the food supply chain and under different conditions. For example,

- When an ethylene scrubber is used in storage rooms, carbon dioxide levels can be 1.7% and oxygen levels 2.2%.

- In cold storage rooms, ethylene could be 4.5%, carbon dioxide 0.1%, and oxygen 20.4%.

- Storage in wooden bins with vents require ethylene levels of 0.07%, carbon dioxide at 0.1%, and oxygen levels at 20.5%.

Modern Measuring Technology

Measuring trace amounts of the gases requires a high degree of accuracy. There are many technologies available; however, not all are suitable for small devices that can be used in the supply chain and production centers. Some of the standard methods are miniature gas chromatography detection, infrared spectroscopy, electrochemical sensing, and pyroelectric detection.

- Miniature gas chromatography detection: A sample of gas from the fruit chambers is injected into a column where nitrogen separates the components. Flame ionization is used to identify the gases and their amounts. This method is useful for oxygen and ethylene and requires bulky equipment and trained personnel.

- Infrared spectroscopy: This optical technology is suitable for incorporation in small and portable devices to measure ethylene, oxygen, and carbon dioxide. It requires no sample preparation and records the fruit’s absorption, reflectance, and emission of infrared light.

- Electrochemical sensing: This method is very sensitive to levels of ethylene, carbon dioxide, and oxygen. In the presence of electricity, the gas reacts chemically with the sensing material to produce an electric signal. This changes either the current or resistance of the electrical circuit, which is then measured.

- Pyroelectric detection: This is a type of thermal sensor, which is used to detect carbon dioxide. It is similar to the technology used in intruder alarm systems and fits into small devices.

Commercial Gas Analyzers

Felix Instruments produces a range of gas analyzers for non-destructive measurement of oxygen, carbon dioxide, and ethylene with resolutions to meet varying needs. They can store thousands of data measurements, which can be transferred with a USB cable. The gas analyzers use electrochemical sensors to analyze oxygen and ethylene, and infrared sensors and pyroelectric detectors for carbon dioxide. Gas analysis can be a trigger or continuous. Measurement times are rapid and require only 10-30 seconds.

- The F-901 AccuStore & AccuRipe are fixed devices that monitor gas levels and regulate the delivery of gases in storage and ripening rooms.

- The F-920 Check It! Gas Analyzer is a portable device that can be used in all stages of the supply chain and in greenhouses.

- The F-940 Store It! Gas Analyzer is a portable device suited for environments in storage rooms and retail shops.

- The F-950 Three Gas Analyzer is also a portable device that measures all three gases. It is ideal for measuring ethylene between 0-200 ppm for a range of fruits and vegetables in greenhouses and the supply chain.

- The F-960 Ripen It! Gas Analyzer gives a combined reading of oxygen, carbon dioxide, and ethylene in ripening rooms. It can even be used from outside the room if there are internal connections. This makes it safe for staff since they can avoid exposure to a high carbon dioxide atmosphere.

Miniaturization of Technology

There has been a focus to increase the precision of measurements in the food supply chain to reduce waste and optimize storage, ripening, and processing. Attempts have been made to miniaturize technology into portable devices so that they can be used outside of a laboratory. Many conventional techniques for analyzing gas concentrations are complex, and it is challenging to incorporate them into small devices. Hence, the availability of a range of gas analyzers, such as those from Felix Instruments, provides a significant boost to the food industry.

—

Vijayalaxmi Kinhal

Science Writer, CID Bio-Science

Ph.D. Ecology and Environmental Science, B.Sc Agriculture

Feature image courtesy of Oh Barcelona

Source

Becker, B.R., & Fricke, B.A.Transpiration and Respiration of Fruits and Vegetables. Retrieved from https://b.web.umkc.edu/beckerb/publications/chapters/trans_resp.pdf

Buis, A. (2019, Oct 9). Sizing Up Humanity’s Impacts on Earth’s Changing Atmosphere: A Five-Part Series. NASA. Retrieved from https://climate.nasa.gov/news/2915/the-atmosphere-getting-a-handle-on-carbon-dioxide/

Cristescu, S.M., Mandon, J., Arslanov, D., De Pessemier, J., Hermans, C., & Harren, F.J.M. (2013). Current methods for detecting ethylene in plants, Annals of Botany, 111: 347–360. DOI: https://doi.org/10.1093/aob/mcs259

FAO. 4.7 Respiration. Retrieved from http://www.fao.org/3/T0073E/T0073E02.htm

Health and Safety Executive/Local Authorities Enforcement Liaison Committee (HELA). Banana (and other fruit) ripening rooms. Retrieved from https://www.catalyticgenerators.com/wp-content/uploads/2015/10/HELA.pdf

Matindoust, S., Baghaei-Nejad, M., Shahrokh Abadi, M., Zou, Z. and Zheng, L. (2016), “Food quality and safety monitoring using gas sensor array in intelligent packaging,” Sensor Review, Vol. 36 No. 2, pp. 169-183. https://doi.org/10.1108/SR-07-2015-0115

Paul, V.; Pandey, R.; Srivastava, G.C. The fading distinctions between classical patterns of ripening in climacteric and non-climacteric fruit and the ubiquity of ethylene—An overview. J. Food Sci. Technol. 2011, 49:1–21. DOI: doi:10.1007/s13197-011-0293-4.

Postharvest Management of Vegetables. Oxygen and carbon dioxide. Retrieved from https://www.postharvest.net.au/postharvest-fundamentals/atmosphere/oxygen-and-carbon-dioxide/

Saltveit, M.E. (2003). Is it possible to find an optimal controlled atmosphere? Postharvest Biology and Technology, 27:3-13. Retrieved from http://ucce.ucdavis.edu/files/datastore/234-2197.pdf

Valente, J., Almeida, R., & Kooistra, L. (2019). A Comprehensive Study of the Potential Application of Flying Ethylene-Sensitive Sensors for Ripeness Detection in Apple Orchards. Sensors, 19: 372. DOI: https://doi.org/10.3390/s19020372

Related Products

- F-751 Grape Quality Meter

- Custom Model Building

- F-910 AccuStore

- F-751 Melon Quality Meter

- F-751 Kiwifruit Quality Meter

- F-750 Produce Quality Meter

- F-751 Avocado Quality Meter

- F-751 Mango Quality Meter

- F-900 Portable Ethylene Analyzer

- F-950 Three Gas Analyzer

- F-920 Check It! Gas Analyzer

- F-960 Ripen It! Gas Analyzer

- F-940 Store It! Gas Analyzer

Most Popular Articles

- Spectrophotometry in 2023

- The Importance of Food Quality Testing

- NIR Applications in Agriculture – Everything…

- The 5 Most Important Parameters in Produce Quality Control

- Melon Fruit: Quality, Production & Physiology

- Fruit Respiration Impact on Fruit Quality

- Guide to Fresh Fruit Quality Control

- Liquid Spectrophotometry & Food Industry Applications

- Ethylene (C2H4) – Ripening, Crops & Agriculture

- Active Packaging: What it is and why it’s important