January 27, 2021 at 2:26 am | Updated January 27, 2021 at 2:26 am | 6 min read

Cold storage facilities aiming to reduce ethylene production and respiration rates in potatoes require considerable power consumption for cooling and ventilation. Lowering power consumption has become a major goal to bring down the costs of storage. A group of scientists who were developing the optimum method of ventilation had to monitor gas exchanges in an effort to provide a commercially attractive balance of power consumption and potato quality preservation. Using the Felix F-900, they were able to make confident, data-driven reccomendations.

Ventilation Can Control Ethylene Gas and Respiration in Controlled Atmospheres

Potato (Solanum tuberosum L.) is the fourth most important food crop and a staple in many regions of the world. To make potatoes available year round, the tuber is stored in controlled atmosphere conditions.

Temperatures higher than 2oC can lead to increased respiration and transpiration, which causes potatoes to lose around 5–8% weight in an 8-10 month storage period. Temperature also triggers ethylene production, which can alter the chemical composition of potatoes and, in later storage periods, enhance the sprouting of the tubers.

Subscribe to the Felix instruments Weekly article series.

By submitting this form, you are consenting to receive marketing emails from: . You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact

During the warm summer months in North America, refrigeration is necessary to keep temperatures low, so potatoes are stored in controlled atmosphere conditions. The closed rooms must have good ventilation to prevent the build-up of ethylene gas, carbon dioxide, and respiration heat, while maintaining the right relative humidity to prevent weight loss and sprouting.

Usually, fans are used to ventilate the cold storage facilities.

Three scientists—Emragia, Sathuvalli, and Jayant—wanted to find the fan speed and duration of use that would ensure ideal ventilation in potatoes while using less power consumption, as there was little research on this topic.

Proper ventilation could prevent ethylene production and microbial spoilage of potatoes.

Challenge: Measuring Ethylene Gas Production and Respiration Rate Non-Destructively

The scientists experimented on Rio Grande Russet potatoes stored in plastic drums for two seasons. The stored potatoes were exposed to continuous and intermittent ventilation with fans operating at speeds of 52 cubic feet per minute (CFM), 13 CFM, and 0.6 CFM; these potatoes were compared to a control with zero ventilation.

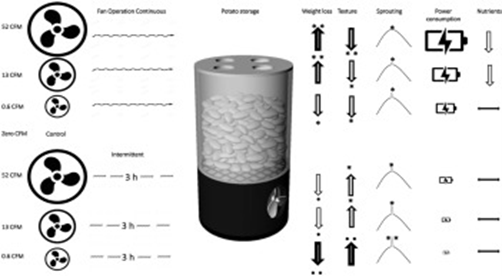

The weight of potato drums was taken at the start of the experiment and after three and six months. At this time, the firmness of the tubers, sprouting rate, ethylene production, and respiration rate were also recorded. The researchers also calculated power consumption for six months in each of the six treatments; see Figure 1.

The scientists needed a tool that could take non-destructive measurements of ethylene, oxygen (O2), and carbon dioxide (CO2) so that no potatoes were sacrificed during the experiment, as the initial and end weight of the whole potato batch was important. Removing tubers three times would make a difference to the weight of the five-gallon drum used for experiments.

Traditional flow and closed systems, which measure the oxygen used for respiration and carbon dioxide produced by respiration, are destructive. The closed system needs at least an hour and can affect the rate of respiration and ethylene production, while the flow system is difficult for low respiring fresh produce.

There are a few non-destructive methods, such as the micro gas chromatography detectors, to measure both ethylene and carbon dioxide. However, these methods are sensitive to changes in the atmosphere that could occur during three repeat measurements. The optical gas detectors’ accuracy in measuring ethylene depends on the type of sensors used, and both instruments are expensive.

As shown in Figure 1, to record gas exchanges for six treatments and replicates, the scientists needed a method that was accurate and simple to use, yet robust enough to be used in a wide range of environmental conditions.

Figure 1: The six treatments with fan speed and duration and associated power consumption are depicted in this representative diagram, Emragia, et al. 2021. (Image credits. https://doi.org/10.1016/j.jafr.2020.100095).

Solution: Felix F-900 Portable Ethylene Analyzer Measures Ethylene, O2, and CO2

By choosing the F-900 Portable Ethylene Analyzer, the scientists found a tool that made non-destructive measurements of not only ethylene, but also O2 and CO2.

They were able to overcome the problem of low volumes of gases associated with flow systems by using F-900, whose high resolution sensors could detect concentrations as little as 0.025 ppm (25 ppb).

The scientists placed three tubers in a one-gallon jar after weighing them. The F-900 was connected to the jar to measure ethylene gas and respiration rate as the ratio of O2 and CO2. Three tests were conducted for each set of treatments at the three designated data collection times: at the start of the experiment and three and six months into the experiment.

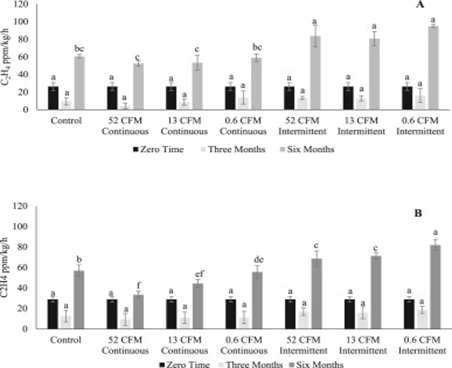

Fig. 2. A & B. “Effect of ventilation condition on ethylene production (ppm/kg/h) by Rio Grande Russet after six months of cold storage at 5 °C ± 2 and RH 95% ± 5 in 2016 (A) and 2017 (B) season,” Emragia, et al. 2021. (Image credits. https://doi.org/10.1016/j.jafr.2020.100095).

Benefits of Using Felix F-900 to Measure Ethylene, O2, and CO2

The F-900, manufactured by Felix Instruments – Applied Food Science, fulfilled the needs of the experiment. It was accurate, low weight, and easy to use.

A significant advantage of the F-900 is that it is designed for commercial use in controlled atmospheres to regulate ventilation. Thus, scientists could use it with a wide range of temperatures (0°C – 45°C) and relative humidity (0-90%).

Moreover, it was designed to detect low ethylene production from even a single fruit and had a high resolution of 0.1 ppm.

The measuring time for individual readings was only one second, and the warm up time to record ethylene was one minute. The 4GB SD card is capable of internal data logging and storage. Therefore, it was simple to record the results of the experiments and later transfer them to computers for statistical analysis.

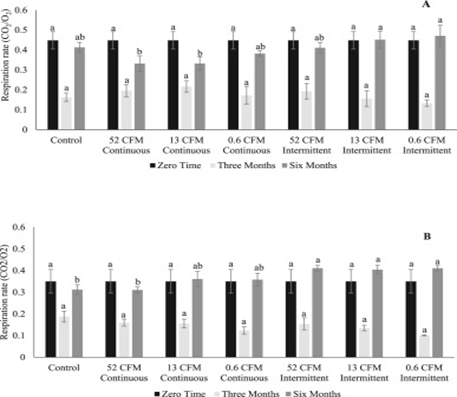

Fig. 3. A & B. “Effect of ventilation condition on the respiration rate of Rio Grande Russet after six months of cold storage at 5 °C ± 2 and 95% RH ± 5 in the 2016 (A) and 2017 (B) season,” Emragia, et al. 2021. (Image credits. https://doi.org/10.1016/j.jafr.2020.100095).

Intermittent Ventilation Improves Potato Storage with Little Power Consumption

Though there was no significant difference in ethylene gas levels among all treatments after three months, scientists saw a variation after six months. The potatoes ventilated with fans that operated continuously had less ethylene compared to tubers ventilated intermittently. Fan speed did not affect either type of ventilation; see Figure 2.

Similarly, respiration didn’t vary after three months. However, after six months, respiration rates were higher with low and medium speed intermittent ventilation than with the fastest continuously operated fan; see Figure 3.

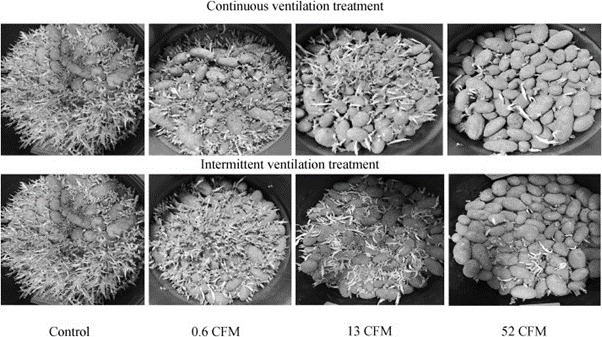

In response to the gas levels, there was a significant difference in sprouting between intermittent and continuous ventilation. The fans that operated with low and medium speeds intermittently had more sprouting; see Figure 4.

Fans that operated intermittently consumed little energy, but medium and high-speed fans that ran continuously consumed significantly more power over the six months.

The scientists found that continuous ventilation resulted in more loss of weight and nutritional value (reducing sugars, total flavonoids, total phenolics, and ascorbic acid) than intermittent ventilation. Moreover, as fan speed decreased, the weight loss also decreased. Intermittent fanning also resulted in more firm potatoes.

Considering all the results, the scientists recommend using low and medium speeds of intermittent ventilation to reduce power consumption and save potato quality and quantity.

Fig. 4. “Effect of different ventilation treatments on the sprouting of Rio Grande Russet. The top row represents continuous ventilation, while the bottom row represents intermittent ventilation,” Emragia, et al. 2021. (Image credits. https://doi.org/10.1016/j.jafr.2020.100095).

Climate-proofing Food Production

Being able to avoid weight loss and spoilage due to sprouting can be a game changer for a major crop like the potato. The method scientists suggested to achieve this breakthrough also significantly reduces current power consumption during an 8-10 month storage period. The distributors can bring down energy costs and increase earnings from higher potato yields, improving the overall ROI. Moreover, the research findings help the food chain adapt to climate change and become more sustainable.

—

Vijayalaxmi Kinhal

Science Writer, CID Bio-Science

Ph.D. Ecology and Environmental Science, B.Sc Agriculture

Feature image courtesy of OliBac.

Sources

Cristescu, S. M., Mandon, J., Arslanov, D., De Pessemier, J., Hermans, C., & Harren, F. J. (2013). Current methods for detecting ethylene in plants. Annals of botany, 111(3), 347–360. https://doi.org/10.1093/aob/mcs259

Emragia, E., Sathuvalli, V., & Jayant, S.S. (2021). The impact of ventilation conditions on the quality of Rio Grande Russet tubers during long-term cold storage. Journal of Agriculture and Food Research, 3. https://doi.org/10.1016/j.jafr.2020.100095

Kader, A.A., & Saltveit, M.E. (n.d.). Respiration and Gas Exchange. Retrieved from https://irrec.ifas.ufl.edu/postharvest/HOS_5085C/Reading%20Assignments/BartzBrecht-2-Respiration%20and%20Gas%20Exchange.pdf

Related Products

- F-751 Grape Quality Meter

- Custom Model Building

- F-901 AccuRipe & AccuStore

- F-751 Melon Quality Meter

- F-751 Kiwifruit Quality Meter

- F-750 Produce Quality Meter

- F-751 Avocado Quality Meter

- F-751 Mango Quality Meter

- F-900 Portable Ethylene Analyzer

- F-950 Three Gas Analyzer

- F-920 Check It! Gas Analyzer

- F-960 Ripen It! Gas Analyzer

- F-940 Store It! Gas Analyzer

Most Popular Articles

- Spectrophotometry in 2023

- The Importance of Food Quality Testing

- NIR Applications in Agriculture – Everything…

- The 5 Most Important Parameters in Produce Quality Control

- Melon Fruit: Quality, Production & Physiology

- Guide to Fresh Fruit Quality Control

- Liquid Spectrophotometry & Food Industry Applications

- Ethylene (C2H4) – Ripening, Crops & Agriculture

- Fruit Respiration Impact on Fruit Quality

- Active Packaging: What it is and why it’s important