November 18, 2020 at 10:26 pm | Updated November 18, 2020 at 10:26 pm | 7 min read

Due to its health benefits, olive oil’s global popularity has grown substantially in recent years, making the olive one of the most extensively grown crops in the world. Since there are different grades of olive oil produced, it is necessary to be able to optimize for both oil quantity and quality. The color index method is not sophisticated enough to detect oil content. Dry matter estimation by NIR spectroscopy, however, has been proven to be a good indicator of oil content and maturity in olives. So, dry matter can be used reliably to fix harvest time, depending on the quality needed, and to select batches of olives based on their oil content for milling.

Dry Matter in Olives

Dry matter (DM) is the portion of the fruit that is made up of all its solids minus water content. This includes structural carbohydrates, starch, sugars, oil, fats, pigments, minerals, and antioxidants. High levels of antioxidants, which carry innumerable health benefits, are a characteristic feature of olive oil. These antioxidants are a special group of polyphenols, hydrophilic phenols, which are found only in olives.

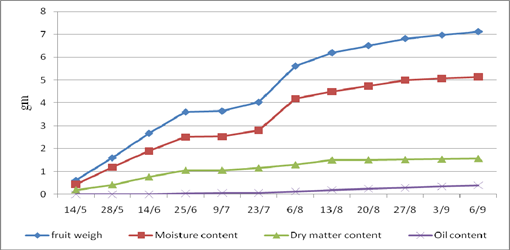

With the increased popularity of DM usage in horticulture, research has proven that in both warm and cool regions of the world there is a linear relationship between dry matter and oil content in olives (See Figure 1).

Subscribe to the Felix instruments Weekly article series.

By submitting this form, you are consenting to receive marketing emails from: . You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact

Figure 1: Changes in fruit weight, moisture, oil, and dry matter contents of “Aggizi shame” olive during the 2011 season, Haggag, et al. (Image credits: http://www.curresweb.com/mejar/mejar/2013/21-27.pdf)

It has been found that dry matter accumulates continuously and increases as the olive fruit grows. Oil begins to accumulate in the fruit when the pits start to harden in July and continues up to November when the fruit is fully ripe and black. Thus, harvesting later can increase the quantity of oil content. However, the oil quality also depends on the harvest date, so it is necessary to be able to monitor the oil content of olives at different stages while they are still on the tree.

For a long time, color index has been used to determine the right time to harvest olives. However, it doesn’t provide any information helpful in producing different grades or qualities of olive oil, such as extra virgin oil, virgin oil, and the inedible lampante virgin olive oil.

Advantages of Using DM

Studies have shown that the correlation between oil content in an intact olive and DM percentage is stronger than with the color of skin.

However, it is important to note that the relationship between DM and oil content is not static across different varieties of olives. For example, a study in New Zealand found that the oil content of Frantoio, Koroneiki, Leccino, and Manzanillo varieties showed a strong correlation to DM percentage, while one outlier, the Barnea variety, did not.

In cooler regions where olives are grown, frost can occur early in the autumn, even before the fruits have achieved the color score 5 required for harvest. It was found that the DM percentage pointing to maximum oil content was reached before the development of color score 5. Therefore, by determining the maturity of olives based on DM content, growers can harvest crops early and avoid yield loss due to frost.

Besides the grower who needs to fix the correct harvest time, millers who produce the oil also need to supervise the quality of olive fruit when it is brought in by the farmer. They prefer to use batches of olives with similar oil content to get a homogenous product. This is far more difficult when only skin color is used; information based on DM content is more relevant here.

Thus, we see it is necessary to measure olives at various stages in the supply line.

Optimum DM content

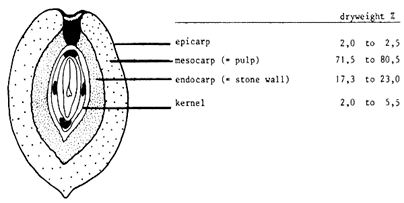

While the pulp contains the highest quantities, olive fruit pulp and seeds both contain oil (See Figure 2). Moreover, the oil from the pulp is rated as higher quality and is more nutritious, as it is rich in antioxidants, such as hydroxytyrosol. The fine taste from extra virgin olive oil comes from hydroxytyrosol, which is missing in the oil from the pits/seeds. Olive oil extracted from the seed increases bulk, but its mixture with pulp oil produces lampante olive oil, which is not consumed.

Figure 2: The olive: (a) cross-section and (b) physical composition, FAO (Image credits: http://www.fao.org/3/X6545E/X6545E01.htm)

The average oil content in olives is 27%, according to FAO, and the ideal DM content of olives can vary from 35–47% based on the variety in the Mediterranean regions.

The oil content will vary in different varieties and also depends on environmental factors. High temperatures of 30oc and above can slow the accumulation of oil content.

Agronomic practices can also influence oil content. By manipulating their practices accordingly, stakeholders can use give their commodities an edge over the competition.

Improving Oil Quality

The necessary agronomic practices depend on whether the farmer aims to maximize the quantity or quality of their oil yield.

Pruning the trees so that all branches are equally exposed to sunlight will reduce yield, but the oil quality in the remaining olives substantially improves.

Harvesting earlier when the olives are still green introduces a fresh, vibrant aroma, and increased polyphenol content in the resulting oil. Once again, this comes at the expense of the quantity of oil extracted, as there is less oil content in younger olives compared to older and riper fruits. Leaving olives longer on the tree ensures they have 20% of oil, whereas an early harvest with an eye on high quality produces olives with only 12 to 13% oil content. Oil from later harvests has a sweet aroma that is not very strong, lower polyphenol content, and shorter shelf life.

DM Estimation Methods

DM can be estimated destructively by using a microwave oven or through modern, non-destructive methods.

Microwave oven method

Fruits from at least ten trees are used to get a sample to test for DM content using a microwave oven. Since it is difficult to separate the pulp from the seeds, whole fruits are used. The drying is done on a low power setting for fifty minutes followed by further five-minute-long periods of drying until a constant weight is derived. This method is destructive, as fruits must be plucked each time the crop is tested, and some minimum laboratory facilities are necessary. This method is also time-consuming and relatively labor-intensive.

Near-Infrared (NIR) Spectroscopy

A non-invasive method of estimating DM, NIR has been successfully utilized with many fruits around the world. In 2010, it was shown for the first time that NIR estimation of DM is reliable and efficient for use to indicate maturity and oil content in olives, and the technology has only grown in popularity since.

By using small field instruments, like the F-750 Produce Quality Meter produced by Felix Instruments Applied Food Science, it is now possible to conveniently measure DM percentage and, therefore, oil content non-destructively at different stages of fruit development and during milling.

In addition to DM percentage, the F-750 provides information on chemical and physical characteristics such as Total Soluble Solids (TSS or Brix), oil content, polyphenol content, acidity, and color.

The measurement of polyphenol content, oil content, and acidity has distinct diagnostic applications in the case of olive oil production. Since hydrophilic phenols are unique to olives, they are used to detect adulteration and in grading olive oils. Levels of acidity are also important in grading olive oils.

Oil content in olives can be measured based on fresh weight and dry weight by using NIR spectroscopy. This is an important parameter for farmers and mills who want to maximize oil yield.

Though NIR spectroscopy is used widely in agriculture, its application in the production of olive oil is new. With the increase in popularity of olive oil, the need for scalable, non-destructive NIR-based measurements is also predicted to rise.

Reliable Technology for Reliable Results

Olives are now grown all over the world, including the Mediterranean region, North and South America, North Africa, New Zealand, and Australia. Common quantitative measures, such as NIR spectroscopy, which can be used for all varieties, remove the guesswork, and are more objective than the use of the color index. With NIR spectroscopy, it is possible to make repetitive and non-destructive assessments of oil content and polyphenols easily and accurately. Since high-quality olive oils command better prizes, it is best to use reliable technology in simple and easy-to-use tools for guaranteed compliance with industry standards.

—

Vijayalaxmi Kinhal

Science Writer, CID Bio-Science

Ph.D. Ecology and Environmental Science, B.Sc Agriculture

Feature image courtesy of Motion Array

Sources

Abesamis, A. (2019, January 23). Here’s Why Good Olive Oil Costs So Much More. Retrieved from https://www.huffpost.com/entry/good-olive-oil_n_5c3e1606e4b0922a21d92752?guccounter=1&guce_referrer=aHR0cHM6Ly93d3cuZ29vZ2xlLmNvbS8&g

Casale, M., & Simonetti, R. (2014). Review: Near infrared spectroscopy for Analysing olive oils. Journal of Near Infrared Spectroscopy. 22. 59-80. 10.1255/jnirs.1106.

Cayuela, J., García, J., García, J., Caliani, N., & Caliani, N. (2009). NIR prediction of fruit moisture, free acidity and oil content in intact olives. Grasas y Aceites, 60(2), 194-202. DOI:http://dx.doi.org/10.3989/gya.097308

Cayuela, J. A. & Camino, M.C.P. (2010). Prediction of quality of intact olives by near infrared spectroscopy. European Journal of Lipid Science and Technology. DOI:10.1002/ejlt.201000372

FAO. Chapter 1: Importance of olive production and olive tree by-products. Retrieved from http://www.fao.org/3/X6545E/X6545E01.htm

Haggag, L., Shahin, M.F.M., Genaidy, E.A.E. & Fouad, A.F. (2013).Changes in Fruit weight, dry matter, Moisture content and Oil percentage during fruit development stages of two olive cultivars. Middle East Journal of Agriculture Research, 2, 21-27. Retrieved from http://www.curresweb.com/mejar/mejar/2013/21-27.pdf

Isa, A. (2018). Olive fruit dry matter and oil accumulation in warm environmental conditions. Iranian Journal of Horticultural Sciences. Special Issue, 35-43.DOI: 10.22059/IJHS.2017.202867.970.

Michael Bradley, M. (2017). Is olive oil made from the flesh or the stone of an olive? Retrieved from

https://www.quora.com/Is-olive-oil-made-from-the-flesh-or-the-stone-of-an-olive

Mickelbart, M.V. & James, D. (2003) Development of a dry matter maturity index for olive (Oleaeuropaea). New Zealand Journal of Crop and Horticultural Science, 31, 269-276, DOI: 10.1080/01140671.2003.9514261

Navarro Soto, J., Satorres Martínez, S., Martínez Gila, D., Gómez Ortega, J., & Gámez García, J. (2018). Fast and Reliable Determination of Virgin Olive Oil Quality by Fruit Inspection Using Computer Vision. Sensors (Basel, Switzerland), 18, 3826. DOI:10.3390/s18113826

Olivia. (2013, February 26). The Health Benefits of Polyphenols in Extra Virgin Olive Oil. Retrieved from http://theolivepress.com/news-blog/the-health-benefits-of-polyphenols-in-extra-virgin-olive-oil#.XZhve1UzbIU

Mahesar, S.S., Lucarini, M., Durazzo, A., Santini, A., Lampe, A.I., & Kiefer, J. (2019). Application of Infrared Spectroscopy for Functional Compounds Evaluation in Olive Oil: A Current Snapshot. Journal of Spectroscopy, 2019, 11 pages. DOI: https://doi.org/10.1155/2019/5319024.

Related Products

- F-901 AccuRipe & AccuStore

- F-751 Melon Quality Meter

- F-751 Kiwifruit Quality Meter

- F-750 Produce Quality Meter

- F-751 Avocado Quality Meter

- F-751 Mango Quality Meter

- F-900 Portable Ethylene Analyzer

- F-950 Three Gas Analyzer

- F-920 Check It! Gas Analyzer

- F-960 Ripen It! Gas Analyzer

- F-940 Store It! Gas Analyzer

Most Popular Articles

- Spectrophotometry in 2023

- The Importance of Food Quality Testing

- NIR Applications in Agriculture – Everything…

- The 5 Most Important Parameters in Produce Quality Control

- Melon Fruit: Quality, Production & Physiology

- Liquid Spectrophotometry & Food Industry Applications

- Ethylene (C2H4) – Ripening, Crops & Agriculture

- Guide to Fresh Fruit Quality Control

- Active Packaging: What it is and why it’s important

- Understanding Chemometrics for NIR Spectroscopy