June 17, 2021 at 10:48 pm | Updated April 11, 2022 at 6:44 am | 6 min read

Several physiological processes, including respiration, affect the quality and shelf life of fruit. The tropical fruit rambutan is an important cash crop. However, little research has been done on improving their postharvest quality. Recently, a group of scientists endeavored to use non-destructive gas analysis to explore potential postharvest treatments that could be useful in extending the quality and shelf life of rambutan.

Storage Problems of Non-Climacteric Rambutan Fruits

Figure 1: Rambutan fruits, Wall et al 2011. (Image credits: https://www.sciencedirect.com/science/article/pii/B9780857090904500159)

Subscribe to the Felix instruments Weekly article series.

By submitting this form, you are consenting to receive marketing emails from: . You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact

Storing non-climacteric fruits is difficult, as they must be plucked only when they are completely ripe. This can reduce the time that fruits can be stored and transported.

Rambutan (Nephelium lappaceum L.) fruits, which are non-climacteric, are harvested when they develop the optimum visual color of red or yellow. Rambutan is similar to lychee and belongs to the same family, Sapindaceae; see Figure 1.

Usually, rambutan can be stored at ambient conditions for only three days after harvest. The first signs of browning and decay can start after just a single day during the storage and transportation process. The peel darkens and splinters, which spoils appearance, and in time the fruit becomes undesirably soft. Furthermore, the crop is susceptible to diseases and pests during storage, which leads to even greater postharvest loss.

Rambutan is an important export crop for Thailand, Malaysia, and Indonesia. Mostly consumed fresh, its short storage time is a disadvantage, but the fruit can be greatly profitable as it is tasty and contains several vital vitamins, carbohydrates, amino acids, and minerals.

Exploring Possible Treatments

Extending the storage time of rambutan can improve market prospects for the growers and producers of this exotic tropical fruit.

Hot water treatment is a popular means of improving postharvest quality in many tropical fruits. Both hot and warm water treatments have been tested successfully to maintain postharvest quality and nutritional value in rambutan. Producers also use an enhanced carbon dioxide (9-12%) atmosphere or modified atmosphere packaging to preserve the appearance of the fruit. However, the two methods have not been used in combination, and the benefits of doing so are unknown.

Therefore, Indonesian agricultural scientists, Setyabudi, Sasmitaloka, Broto, Prabawati, and Setyadjit, conducted a study where they combined the hot water treatment and controlled atmosphere storage to check for effects on postharvest quality and extension of storage time.

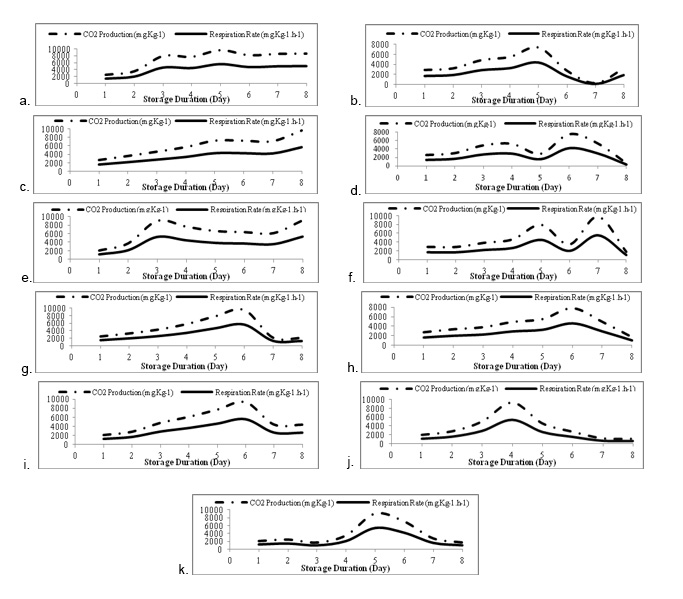

Fig. 2: “CO2 production and respiration rate of rambutan stored at ambient temperature with dipping treatment: a)40°C for 2’; b) 40°C for 4’; c) 40°C for 6’; d) 40°C for 8’; e) 40°C for 10’; f) 50°C for 2’; g) 50°C for 4’; h) 50°C for 6’; i) 50°C for 8’; j) 50°C for 10’; and k) without dipping,” Setyabudi et al. 2021, (Image credits: http://www.jonuns.com/index.php/journal/article/viewFile/512/509)

Testing Heat Treatment and Cold Storage with Gas Analysis

The scientists chose to experiment with the rambutan cultivar, LebakBulus. They harvested the fruits in the afternoon, choosing rambutans that were uniformly ripe, red in color, and of the same size. They inspected the fruits to confirm that the fresh produce was free of diseases, pests, and any other quality problems. Then, the scientists immediately took the fruits to the laboratory and treated them with hot water.

The fruits were dipped in hot water at 40°C and 50°C for 0, 2, 4, 6, 8, and 10 minutes. After the hot water treatment, the fruits were drained and packed in polyethylene bags. Each bag had six perforations and contained eight rambutans. Fruits of all 12 hot water treatments were stored at ambient temperatures of 28–30°C and controlled temperatures of 10–18°C for eight days; see Figure 2.

Data was collected for moisture content, weight loss, and respiration rate of fruits every day the fruits were in storage.

To calculate weight loss, the scientists measured the weight of the fruits before storing them and on all eight days. To find the moisture content, they used the oven drying method, during which 5 grams of fruit sample was desiccated at 105°C for 5 hours.

To measure the respiration rate, the scientists used a precise gas analysis tool. They needed a method that would provide rapid and consistent measurements, while also being sensitive to small changes in the levels of carbon dioxide (CO2). However, gas analysis of CO2 can be tedious and laborious using standard laboratory techniques. Hence, the agricultural scientists decided to use a robust, portable instrument, the F-950 Three Gas Analyzer, produced by Felix Instruments – Applied Food Science.

The scientists first placed one fruit for an hour in a two-liter glass jar at 23°C and 85% relative humidity. The gas analysis was done by using the closed method and measured the gases inside the jar. The individual readings can be made in 12 seconds. The gas analyzer can detect a lower limit of 0.50% in headspace measurements and 0.01% for CO2 during continuous measurements. The scientists expressed the respiration rate as CO2 produced in mL kg-1 h-1.

Combination of Treatments is Optimal

Moisture content in fruits is crucial for freshness, taste, flavor, and tenderness. However, postharvest fruits will continue to transpire and respire. This raises their temperature and causes a loss of water content.

Rambutan has a high density of stomata on the pericarp and loses water vapor even under low temperatures. Moreover, splintering in the peel increases water loss. The rate of transpiration depends on the rate of respiration. The heat produced by respiration drives transpiration and the growth of microorganisms. Thus, in rambutans, the moisture content of fruits decreases gradually until the 4th day in storage, and then, after the sixth day, rises steeply as a result of microbial activity.

Hot water treatment kills many of the microorganisms on the peel and slows respiration and transpiration. As a result, fruits that are dipped in hot water lose their moisture content more slowly. Loss of moisture will affect the fruit quality by causing wilting, wrinkling, and loss of weight.

Hot water treatment was found to reduce weight loss significantly. Usually, fruits retain their weight when cold-stored. However, comparison of rambutans stored at ambient and cool temperatures did not show notable difference in weight loss. Hence, the scientists concluded that the reduction in weight loss was due to the hot water treatment alone, and not storage temperature.

Respiration rate is influenced by weather conditions like temperature, relative humidity, and O2 and CO2 levels. Intrinsic factors, such as variety, season, and the growing site will also influence postharvest fruit respiration. Non-climacteric fruits do not usually undergo large hikes in respiration rate. However, the rambutan is unusual and shows respiration rates characteristic of climacteric fruits.

The high respiration in rambutans suggests that classifying fruits in just two categories (climacteric and non-climacteric) is an oversimplification.

The respiration rate and production of CO2 increases in untreated fruits stored at ambient temperatures, from the third to the 50th day, due to ripening and then decreases due to the onset of senescence. The peak of the respiration rate can be taken as the point at which the quality of fruits is good.

Hot water treatments alone manage to improve shelf life. At ambient temperatures, fruits treated with 40°C hot water for two, four, and six minutes continue to show a rise in respiration rate and CO2 levels, even on the eighth day. This suggests that the peak of ripening has not been reached and that these fruits can be stored more than eight days without loss of fruit quality.

Storing rambutans at cool temperatures alone will also delay ripening. Untreated rambutans in cool temperatures delay ripening by one day; they start peaking from the fourth to the sixth day. However, by far, the best results were seen in fruits treated with hot water and stored in cool stores. These fruits show the lowest respiration rate and CO2 production when they are treated in hot water for six, eight, and ten minutes.

The hot water treatment before cold storage delays the peaking of ripening and lowers respiration rates more than cool storage alone. Hence, combining the two treatments is an optimal. The scientists recommend treating the rambutans with 40–50°C hot water for six to 10 minutes, and storing them at controlled temperatures of 10–18°C.

The results show that fruits in many of the treatments have not yet reached their respiration peak even on the eighth day. It might be useful to conduct the same experiment, over longer periods up to 2-3 weeks, to find out when the fruits reach their respiration peak in order to establish the full potential of the combination of treatments in extending the shelf life.

Small Steps and Big Results

Hot water treatment at a moderate temperature of 40-50°C is easily done with no special equipment. It is low cost and can be undertaken on any farm. Keeping the rambutans in cool stores after the treatment will extend shelf life and postharvest quality beyond eight days, giving producers a longer window of sales time in the national markets.

However, the scientists rightly caution that both treatments must be undertaken with specialized equipment to maintain temperatures precisely if the fruits are to be exported. Even then, they are not sure the treatments are enough to control diseases and pests. Though further research is needed, this study is an excellent start in combining known and non-chemical methods in enhancing storage time and fruit quality, which opens the door for use in organic fruit as well.

—

Vijayalaxmi Kinhal

Science Writer, CID Bio-Science

Ph.D. Ecology and Environmental Science, B.Sc Agriculture

Feature image courtesy of Angga Siswanto

Sources

Setyabudi. D.A., Sasmitaloka, K.S., Broto, W., Prabawati, S., & Setyadjit. (2021). Effect of Hot Water Treatment on Quality and Shelf-Life of Rambutan. Journal of Hunan University. 48 (2). Retrieved from http://www.jonuns.com/index.php/journal/article/viewFile/512/509

Related Products

- F-751 Grape Quality Meter

- Custom Model Building

- F-910 AccuStore

- F-751 Melon Quality Meter

- F-751 Kiwifruit Quality Meter

- F-750 Produce Quality Meter

- F-751 Avocado Quality Meter

- F-751 Mango Quality Meter

- F-900 Portable Ethylene Analyzer

- F-950 Three Gas Analyzer

- F-920 Check It! Gas Analyzer

- F-960 Ripen It! Gas Analyzer

- F-940 Store It! Gas Analyzer

Most Popular Articles

- Spectrophotometry in 2023

- The Importance of Food Quality Testing

- NIR Applications in Agriculture – Everything…

- The 5 Most Important Parameters in Produce Quality Control

- Melon Fruit: Quality, Production & Physiology

- Fruit Respiration Impact on Fruit Quality

- Guide to Fresh Fruit Quality Control

- Liquid Spectrophotometry & Food Industry Applications

- Ethylene (C2H4) – Ripening, Crops & Agriculture

- Active Packaging: What it is and why it’s important