July 1, 2021 at 5:04 am | Updated April 11, 2022 at 6:44 am | 7 min read

Kiwifruit has become commercially popular world-wide in the past four decades. The growing demand makes long transport and storage times inevitable. Dry matter is a reliable parameter to control harvest time and quality for many fruits. In the case of kiwifruits, dry matter provides additional insights that have helped to shape best practices for kiwifruit cultivation and post-harvest handling. Estimating dry matter during various stages of its production has become crucial for sustaining a profitable kiwifruit industry.

Dry Matter in Kiwifruit

Dry matter is a measure of all the solid components in a plant, minus water content. In kiwifruit, dry matter is mainly composed of soluble solids such as sugars and insoluble solids such as starches and carbohydrates. Other compounds like proteins, pigments, etc., are also part of dry matter

Subscribe to the Felix instruments Weekly article series.

By submitting this form, you are consenting to receive marketing emails from: . You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact

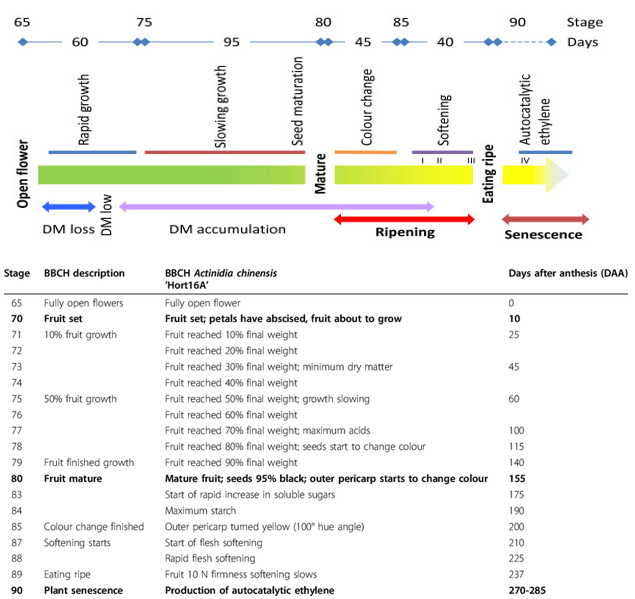

Figure 1 and Table 1: Fruit development and dry matter accumulation in the kiwifruit. From Richardson et al. 2011. (Image and table credits: DOI: 10.1186/1471-2229-11-182 )

The kiwifruit accumulates dry matter from fruit-set well into the ripening process; it is thus associated with many stages of kiwifruit development. Therefore, the dry matter level can determine harvest time, keeping in mind consumer satisfaction.

There are many other reasons for using dry matter as an indicator of maturity and quality for kiwifruit.

- Soluble solids content (SSC), which can measure only sugars, is unable to account for the post-harvest conversion of starch to sugars in climacteric fruits like kiwifruit. Since dry matter at harvest includes both starch and sugars, it can be correlated with post-harvest sugars or sweetness.

- Dry matter is also sensitive to growing conditions and agricultural practices and will vary with season, location, and harvest date, which provides information on the quality of orchards.

- Dry matter does not change during the storage period, post-harvest.

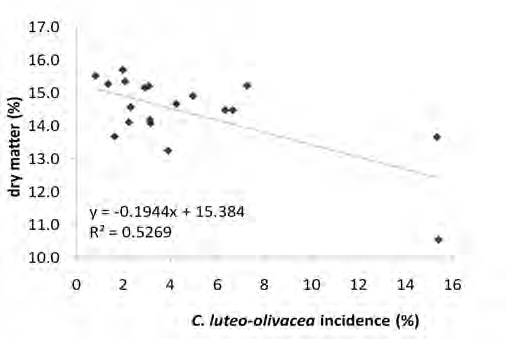

Dry matter can be used to predict the incidence of skin pitting, a disease caused by Cadophora luteo-olivacea, a fungus, during storage.

Optimum Dry Matter Content

A dry matter range of 15% to 20% was earlier associated with consumer satisfaction. These standards have now been revised. The accepted standard is ~16% dry matter to get good quality fruits and ensure long and safe storage.

The optimum dry matter content to determine various aspects of kiwifruit handling is discussed below.

Quality and Taste

Dry matter of less than ~15-16% in kiwifruit, which can result due to early harvest or growth in inferior orchards, do not often meet consumer satisfaction.

Moreover, keeping in mind the final fruit quality, in kiwifruits, the desirable dry matter to predict maturity is connected with ripe titratable acidity (RTA).

- A dry matter of ~16% is considered the minimum for quality kiwifruits.

- If the RTA is less than 1.2%, then a dry matter of ~15% can also be acceptable.

- A minimum of ~16% dry matter should accompany RTA that is equal to or more than 1.2%

Often, industry organizations will also set specific guidelines for growers that must be met for fruit to be accepted. These guidelines can differ slightly between cultivars and across regions.

Storage Time

If kiwifruits have a very high level of sugars or SSC, they tend to be soft and cannot be stored long. If the sugar levels are too low, the fruits won’t meet taste standards. Since dry matter at harvest is correlated with SSC after harvest, it has been established that:

- For kiwifruit to have a minimum of 14% SSC after the storage period, fruits must have a minimum of 14-15% dry matter at harvest.

- The maximum desirable level of SSC is 16%. To ensure that kiwifruits do not have more sugars, dry matter should not exceed 18.19% during harvest.

Preventing Postharvest Diseases

The skin pitting disease in kiwifruits reduces storage time and can destroy substantial portions of the harvest. There are many factors which influence the occurrence of skin pitting during storage, such as time to achieve the right controlled atmospheres (CA), i.e., levels of oxygen and carbon dioxide. However, when CA conditions are ideal, low dry matter and high nitrogen content in fruits make them susceptible to the fungus. A higher dry matter level at the start of storage can reduce or prevent skin pitting.

- Fruits with dry matter of 10.55% to 13.66% are likely to suffer heavily from skin pitting.

- Fruits with a minimum of 15.38% of dry matter are more hardy against the fungal attack.

Figure 2: Incidence of skin pitting caused by Cadophora luteo-olivacea, decreases with increasing dry matter content in the kiwifruit. From Spadaro et al. 2010 (Image credits: http://www.jstor.org/stable/41998808 )

How to Measure Dry Matter of Kiwifruit

Just as in other fruits, there are destructive and non-destructive methods of estimating dry matter content of kiwifruits.

The destructive methods are laborious, time consuming, and cannot be carried in the field, as the tests require laboratory conditions. However, the results achieved are precise.

- Fruit Dehydrator: Fruit samples are made, and fresh weight is taken. The samples are then dried in a fruit dehydrator until there is no water content left. The dry weight is calculated as a percentage of the wet weight.

- Oven Drying: This method is used in laboratories for scientific studies. It involves taking fruit samples and getting its fresh weight and then dry weight to calculate dry matter.

New Methods with Near Infrared Spectroscopy

There are new non-destructive methods to estimate dry matter. They are often designed as small handheld devices that can quickly and accurately measure dry matter in the fields, laboratories, and classrooms.

Near Infrared (NIR) spectroscopy is one of the most popular and reliable methods. Light reflected in various wavelengths by solid components of the fruit is recorded using spectroscopy to give an estimate of their proportions.

The recently upgraded F-751 Kiwifruit Quality Meter, produced by Felix Instruments – Applied Food Science uses NIR spectroscopy to estimate dry matter. The F-751 is simple, lightweight, and user-friendly.

- The F-751 can display results in as little as 12 seconds.

- It has an integrated GPS for repeat readings and tree mapping.

- The device has integrated software for storage and data transfer to computers.

Besides measuring dry matter, the F-751 can also estimate soluble solids (SSC), titratable acidity, and color of fruits. Since optimum dry matter values for harvest are connected with titratable acidity, this device is ideal for kiwifruit growers.

Best practices for Dry Matter

Given the importance of dry matter, agricultural practices have been refined to improve dry matter content of kiwifruits. Some common suggestions are:

- Avoid over-watering kiwifruit by monitoring soil moisture levels closely and by choosing the correct mode of irrigation.

- Use pergolas to trail the kiwifruit vines so that fruits are borne on raised vines with better exposure to the sun. When vines are allowed to trail to the ground in a T support, kiwifruits near the ground get less sunlight, resulting in lower dry matter.

- Kiwifruit vines should have an open canopy in all seasons. Choose a variety with medium winter growth – not one that is too weak or too vigorous – to get a good balance of vegetative growth and dry matter content.

- Prune vines to control excessive vegetative growth in early summer through tip crushing and by removing shoots. Pruning allows sunlight to reach lower canopy and increase dry matter content and fruit size. Putting off pruning to January or later in late summer will decrease dry matter in fruits.

- Summer trunk girdling can improve dry matter %, fruit size, and taste. However, girdling increases sugar content during harvest, making the fruits softer and decreasing potential storage time.

- Monitor vegetative growth to ensure the leaves are healthy to get more dry matter in kiwifruits.

Best practices on Harvesting and Storing Kiwifruit

Besides controlling dry matter skin pitting can be prevented to control fruit losses by following some additional growing and storage practices mentioned below.

- As low calcium content in kiwifruits causes skin pitting, spray calcium chloride on vines. Calcium chloride treatments increase the firmness of fruits and extend storage time by 10 to 12 weeks.

- Controlled atmospheres (CA) monitoring in storage facilities should decrease oxygen levels to 2% and increase carbon dioxide levels to 4.5%, at 0.5°Cslowly throughout a 45-day period. A rapid establishment of CA within 12 days stresses the fruit, making it weak and susceptible to disease.

- Kiwifruits that have low dry matter and calcium, and high nitrogen content, should not be stored long to prevent fruit loss. Additionally, the CA should be monitored closely to prevent skin pitting.

Dry Matter Estimation is Vital

Dry matter estimation helps growers of kiwifruits in many ways; from estimating time of harvest, maintaining the quality of fruits, preventing postharvest diseases, to extending storage time. Especially in cases of kiwifruits meant for international sale, quick and easy dry matter estimation can decrease risks and increase profits for stakeholders at all levels.

—

Vijayalaxmi Kinhal

Science Writer, CID Bio-Science

Ph.D. Ecology and Environmental Science, B.Sc Agriculture

Sources

Cantin, C.M., Soto, A., Crisosto, G.M. and Crisosto, C.H. (2011). Evaluation of a non-destructive dry matter sensor for kiwifruit. Acta Hortic. 913, 627-632. DOI: 10.17660/ActaHortic.2011.913.86

Crisosto, C.H., Zedge, J., Hasey, J., & Crisosto, G.M. (2012). New quality index based on dry matter and acidity proposed for Hayward kiwifruit. California Agriculture, Berkeley, 66, 70-75. Retrieved from http://californiaagriculture.ucanr.edu

Hall, A., & Snelgar, B. (2012). Prediction of harvest dry matter in ‘Hayward’ kiwifruit.

Retrieved from https://www.plantandfood.co.nz/file/kiwifruit-resource-krf2012-prediction-harvest-dry-matter.pdf

Richardson, A., Boldingh, H.L., Mcatee, P. A., Gunaseelan, K., Luo, Z., Ross, R.G., David, K.M., Burdon, J.N., Schaffer, R. J. (2011). Fruit development of the diploid kiwifruit, Actinidia chinensis ‘Hort16A’. BMC plant biology. 11. 182. 10.1186/1471-2229-11-182.

Spadaro, D., Galliano, A., Pellegrino, C., Gilardi, G., Garibaldi, A., & Gullino, M.L. (2010). Dry matter, mineral composition, and chemical storage practices influence the development of skin pitting caused by Cadophora luteo-olivacea on kiwifruit ‘Hayward.’ Journal of Plant Pathology, 92(2), 349-356. Retrieved from http://www.jstor.org/stable/41998808

Spark, S. (2008, November). Enhancement of dry matter in Nelson kiwifruit. Year Three Final Report. Retrieved from http://www.agfirstbop.co.nz/media/docs/final-report.pdf

Taste. Retrieved from https://www.nzkgi.org.nz/communications-grower-guidance/taste/

Travers, S. (2013). Dry matter and fruit quality: Manipulation in the field and evaluation with NIR spectroscopy. Ph.D. thesis submitted to Dept. of Food Science, Faculty of Science and Technology, Aarhus University. Retrieved from https://pure.au.dk/ws/files/56894564/Dry_matter_and_fruit_quality_manipulation_in_the_field_and_evaluation_Sylvia_Travers_Thesis_August_2013_compressed_opt.pdf

Velemis, D., Vasilakakis, M., & Manolakis, E. (1997). Effect of dry matter content of the kiwifruit at harvest on storage performance and quality. Acta Hortic. 444, 637-642 DOI: 10.17660/ActaHortic.1997.444.98

Related Products

- F-751 Grape Quality Meter

- Custom Model Building

- F-901 AccuRipe & AccuStore

- F-751 Melon Quality Meter

- F-751 Kiwifruit Quality Meter

- F-750 Produce Quality Meter

- F-751 Avocado Quality Meter

- F-751 Mango Quality Meter

- F-900 Portable Ethylene Analyzer

- F-950 Three Gas Analyzer

- F-920 Check It! Gas Analyzer

- F-960 Ripen It! Gas Analyzer

- F-940 Store It! Gas Analyzer

Most Popular Articles

- Spectrophotometry in 2023

- The Importance of Food Quality Testing

- NIR Applications in Agriculture – Everything…

- The 5 Most Important Parameters in Produce Quality Control

- Melon Fruit: Quality, Production & Physiology

- Guide to Fresh Fruit Quality Control

- Liquid Spectrophotometry & Food Industry Applications

- Ethylene (C2H4) – Ripening, Crops & Agriculture

- Fruit Respiration Impact on Fruit Quality

- Active Packaging: What it is and why it’s important