June 3, 2021 at 10:27 pm | Updated April 11, 2022 at 6:44 am | 5 min read

Developing countries lose disproportionate amounts of grain due to insect attacks during storage. In the search for efficient solutions suitable for varying budgets, a team of Indian scientists investigated grain storage methods for black gram crops. Since respiration is the major physiological process during storage, it was not surprising that carbon dioxide and oxygen measurements led to significant discoveries.

Grain Storage Options

Although India is the largest producer of several pulse varieties, it cannot produce enough of them to meet domestic demand and imports these grains to meet. On the other hand, about 10-15% of cereals and pulses produced in India are lost before they reach consumers, according to a UN report. As in any other developing country, much of this—around 40%—occurs post-harvest.

Proper storage can prevent loss of quality and yield, boost access to pulses, and stabilize prices during the off-season. This is also true for the black gram crop (Vigna mungo), popular in south India.

Subscribe to the Felix instruments Weekly article series.

By submitting this form, you are consenting to receive marketing emails from: . You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact

The main causes for storage loss in pulses are diseases and pests, such as rodents and insects. Insects account for 10-50% of post-harvest losses, and the main culprit is the pulse beetle (Callosobruchus maculatus). Fumigating with chemicals is not popular as a grain storage method, as it is a health hazard for people. Moreover, the insects are developing resistance against common insecticides.

In search of better solutions on how to store grains, people are turning back to an older storage technique: hermetic storage. Hermetic storage involves storing grains in a low oxygen environment to reduce insect numbers by affecting survival and reproduction. Low oxygen concentrations are also known to extend storage time by reducing respiration in the food being stored.

As a grain storage method, hermetic bags have several advantages:

- They require no chemical or biological intervention

- They are cheaper than chemical alternatives

- The technique is suitable also for the organic production of pulses

For effective hermetic storage, it is necessary to use a bag made of material that acts as a good barrier for gas movements. To find out what material was best suited for hermetic grain storage, a group of Indian agricultural scientists tested several alternatives.

Testing Grain Storage Methods

The agricultural scientists, Shankar, Pandiarajan, and Ganapathy, tested four materials: GrainPro bags, Storezo bags, a metal bin, and woven polypropylene bags. Grains stored in standard woven polypropylene bags, used for general purposes, were taken as control.

Each material had a different thickness and was composed of different materials. Hence, the water vapor (H2O) and oxygen (O2) transmission through the material varied.

- Metal bins made of steel do not allow the movement of gases.

- GrainPro bags made of multilayered polyethylene allowed 8g/m2/day of H2O and 3 cc/m2/day of O2.

- Storezo bags with inner jute and outer polypropylene layers allowed 2.14g/cm2/day of H2O and 4.28 cc/m2/day of O2.

- Woven Polypropylene bags allowed 4.37 g/cm2/day of H2O and 5.91 cc/m2/day of O2.

The scientists stored 20 kgs of freshly harvested black gram variety VBN67, in each replicate, for two months. A 12% moisture content in pulses was maintained at the start of the storage period. Known numbers of adult C. maculatus, reared at 30oC, were introduced into the four hermetic grain storage methods.

Both the grains and insects respire. This changes the environment inside the content in the grain storage methods, in terms of gas levels (for carbon dioxide and oxygen), temperature, and moisture. The scientists monitored these changes throughout the experiment.

Moisture content was estimated by the oven method, while temperature and relative humidity were estimated by respective USB data loggers. For CO2 and O2 measurements, the agricultural scientists used a gas analyzer. The F-950 Three Gas Analyzer, manufactured by Felix Instruments, can simultaneously measure both gas concentrations.

The F-950 is a small, handheld, Infrared based device designed to control gas concentrations in the postharvest supply chain. Therefore, it is convenient to use. It is also sensitive enough to measure even small amounts of gases that accumulate in controlled atmosphere storage. Individual measurement takes less than half a minute. There is a 16 GB SD card data logger that can store information and easily transfer it later to a computer.

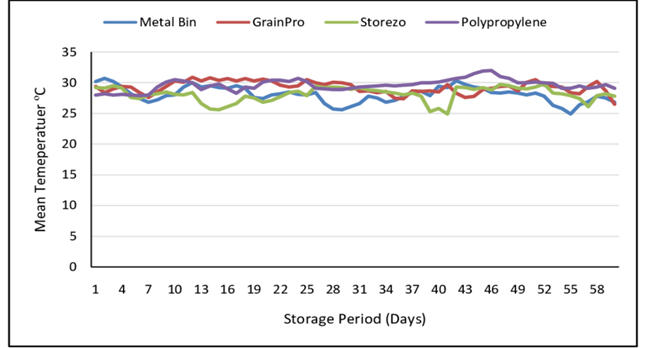

Figure 1: “Temperature inside the bin and bags in hermetic storage,” Shankar et al 2019. (Image credits: Indian Journal of Entomology, 81(2), 390. doi:10.5958/0974-8172.2019.00042.7 )

O2 and CO2 Measurements Uncover Variations In Insect Mortality

Over the two months that the pulses were stored, temperature and relative humidity fluctuated greatly in all four of the grain storage methods tested. However, there was no significant difference in temperature in the four methods, as shown in Figure 1. It is worth noting that temperatures in woven polypropylene bags were the highest at 32oC.

There was a significant difference in moisture content between bags, and it increased in all methods except the metal bins. The scientists put this down to the hygroscopic nature of the black gram crop.

Grains stored in GrainPro and Storezo bags showed similar moisture content levels as those in the metal bin. Once again, the highest moisture content was seen in the polypropylene or control bags.

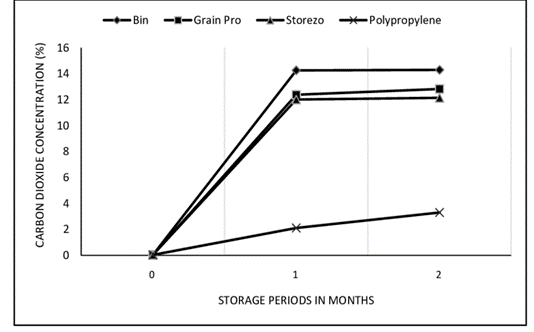

As shown in Figure 2, the level of CO2 rises steeply in the first month to 12-14%. The CO2 is produced by grains and insects during respiration, while the O2 is used by insects for respiration and falls to only 1-2% by two months. After just a few days, when O2 levels fall to 4%, the insects stop feeding. Once the O2 levels reach 3%, the insect development stops entirely.

However, there is a significant difference in CO2 levels from the initial 0.03%. The CO2 measurements showed there was a rise to 15.37%, 14.83%, 15.27%, and 3.37% in metal bin, GrainPro, Storezo, and control, respectively. The variation in CO2 levels is reflected in the insect mortality rates in the different grain storage methods.

At the end of two months, the highest insect mortality of 95% was seen in metal boxes, and 90% mortality of insects was seen in black gram stored in GrainPro and Storezo. There was only 30-50% insect mortality in polypropylene bags, as they had less CO2.

Figure 2: “Effect of hermetic storage on gas concentration,” Shankar et al 2019. (Image credits: Indian Journal of Entomology, 81(2), 390. doi:10.5958/0974-8172.2019.00042.7 )

As the results show, the two bags,–GrainPro and Storezo—and metal bins act as effective barriers between the environment inside and the external atmosphere. This helps in maintaining temperatures, relative humidity, and grain moisture levels. On the other hand, they retain the CO2 produced by the respiration of pulses and insects to ultimately kill the insects.

All three solutions are scalable, since more bags/bins can be used to accommodate larger harvests. Moreover, the three methods do not need expensive capital costs and investment to procure or operate equipment needed to create controlled-atmosphere storage. Naturally occurring respiration in hermetic containers will produce the conditions ideal for extending storage time.

Carbon Dioxide and Oxygen Measurements Are Crucial

O2 and CO2 measurements were vital to explain the functioning of the new grain storage methods. The experiment designed by the agricultural scientists was simple yet elegant, as it simultaneously targeted the process and end result, when they chose to measure respiration. Luckily, there are precise yet portable instruments available to make O2 and CO2 measurements easily. These tools can be used even in the supply chain to ensure that the needed levels of gases are maintained while storing pulses to reduce post harvest loss of food.

—

Vijayalaxmi Kinhal

Science Writer, CID Bio-Science

Ph.D. Ecology and Environmental Science, B.Sc Agriculture

Sources

Shankar, V. S., Pandiarajan, T., & Ganapathy, S. (2019). Hermetic storage of black gram in metal bin and flexible storage bags. Indian Journal of Entomology, 81(2), 390. doi:10.5958/0974-8172.2019.00042.7

UNEP. (n.d.). Worldwide food waste. Retrieved from https://www.unep.org/thinkeatsave/get-informed/worldwide-food-waste

Related Products

- F-751 Grape Quality Meter

- Custom Model Building

- F-910 AccuStore

- F-751 Melon Quality Meter

- F-751 Kiwifruit Quality Meter

- F-750 Produce Quality Meter

- F-751 Avocado Quality Meter

- F-751 Mango Quality Meter

- F-900 Portable Ethylene Analyzer

- F-950 Three Gas Analyzer

- F-920 Check It! Gas Analyzer

- F-960 Ripen It! Gas Analyzer

- F-940 Store It! Gas Analyzer

Most Popular Articles

- Spectrophotometry in 2023

- The Importance of Food Quality Testing

- NIR Applications in Agriculture – Everything…

- The 5 Most Important Parameters in Produce Quality Control

- Melon Fruit: Quality, Production & Physiology

- Fruit Respiration Impact on Fruit Quality

- Guide to Fresh Fruit Quality Control

- Liquid Spectrophotometry & Food Industry Applications

- Ethylene (C2H4) – Ripening, Crops & Agriculture

- Active Packaging: What it is and why it’s important