October 21, 2020 at 9:14 pm | Updated October 21, 2020 at 9:14 pm | 6 min read

Tomatoes are the most consumed fresh produce globally. While dry matter, BRIX, and acidity are well-established quality parameters used in the whole supply chain of many fruits, their use in tomato production has not been fully realized. This article will show how quality meters could be used at the farm level, during sorting and packing, and at retailers, to increase profits from existing crops.

Food Loss at Different Points of the Supply Chain

Tomatoes (Lycopersicon esculentum) are the number one fresh produce consumed in the world. About 37,266 million tonnes of it were produced worldwide in 2019.

Food loss occurs when part of the harvest doesn’t reach the market because of various problems. The Food and Agriculture Organization (FAO) found that losses occur at harvest, sorting, and at retailers. In developing countries, around 50% of the fresh produce grown doesn’t reach the markets, while in developed countries, the loss is about 20-30% of the crop.

Subscribe to the Felix instruments Weekly article series.

By submitting this form, you are consenting to receive marketing emails from: . You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact

A study of tomato loss worldwide, using statistics from a 2011 FAO report, found that

- farm-level losses account for 10% of the crop in Asia, and 20% in Europe, North America, Oceania, and Latin America,

- post-harvest handling losses are 3-4% of the original harvest in developed countries and up to 10% in Africa,

- And transport and storage losses amount to 5% of the crop in Europe, North America, and Oceania, but can vary from 10-20% for Africa, Asia, and Latin America.

Since tomatoes are nutritious and commonly used as vegetables around the world, this is a tremendous loss for people and society, not to mention the economy and the environment.

The use of simple tools can prevent much of this loss. There have been several studies reported, especially in the last five years, that proves that Near Infrared (NIR) spectroscopy is useful at various stages of tomato production.

NIR Spectroscopy

NIR is the spectrum of light that lies next to the red color. It is not visible to the human eye. However, the chemical bonds in the organic compound that makeup plants vibrate in response to them. Based on these vibrations, it is possible to identify chemical compounds and the concentrations in which they are present; this is called spectroscopy.

NIR spectroscopy is a sophisticated process that was conducted earilier with bulky and costly laboratory equipment. However, technological advancements have miniaturized the method to fit in small handheld tools, which can be used outside in fields, farms, warehouses, and shops.

The F-750 Produce Quality Meter, manufactured by Felix Instruments Applied Food Science, is an example. The tools direct a beam of NIR light at the sample and record the absorbance, reflectance, and transmission. Within seconds, it can measure dry matter, total soluble solids, water content, titrable acidity, and internal and external fruit color.

The F-750 is a general instrument that is used for a wide range of fresh produce, and it is also useful for tomatoes. Models can be customized for any fruit or vegetable using the clear instructions given.

The main advantages of using the NIR tool are non-destructive analysis and saving time, cost, and space.

Since the readings are non-destructive, the device can be used several times during production to test fruits and vegetables without wasting produce. This technology also eliminates the need to use toxic chemicals.

Application of NIR Spectroscopy in Tomatoes

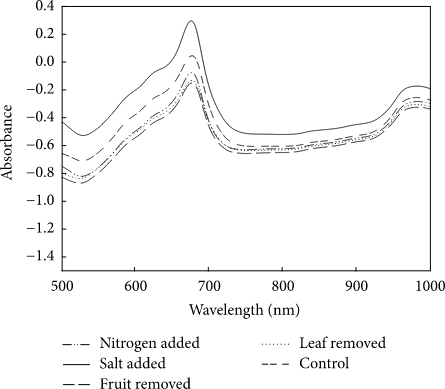

Figure 1: Absorbance peak at 675nm due to chlorophyll. (Image credits: https://doi.org/10.1155/2017/2863454)

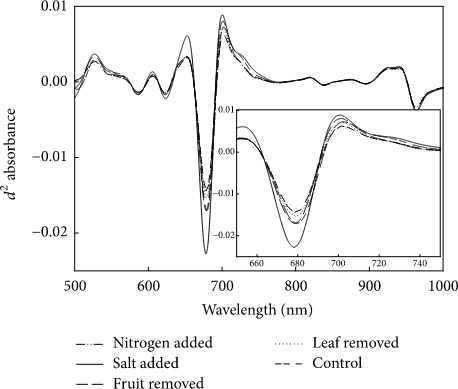

Figure 2: NIR absorbance by tomatoes peak at 575nm due to lycopene, and at 840nm and 960nm due to water. (The dip at 675 is due to loss of chlorophyll during treatments like removal of fruits and leaves and the addition of salt and nitrogen.). (Image credits: https://doi.org/10.1155/2017/2863454)

In tomatoes, total soluble solids measured by Brix, dry matter content, and acid content are attributes that have long been established as quality indicators for tomatoes that can be measured by NIR. However, few of them found applications in ready-to-use technology.

- Dry matter is the total weight of a fruit minus its water content. This measure is important, especially for the processing industries, as it is a measure of the pulp that the vegetable contains. Dry matter can contain 4-8% of insoluble solids and soluble solids, and tomatoes with higher dry matter are preferred.

- Total soluble solids (TSS) make up 75% of the dry matter in tomatoes. Sugars makeup 55-65% of all TSS and can be measured by BRIX. They are an indicator of the sweetness of the fruit.

- Ascorbic acid content in tomatoes is the commonly measured acid used to judge taste.

- Lycopene content increases and replaces chlorophyll as the tomato ripens. Lycopene produces the red color and makes up 75–83% of all pigments at the final ripeness stages. This chemical is also a nutraceutical of interest for people.

Recent studies have found that Near Infrared spectroscopy can differentiate ripening at six different stages, from fully green to fully ripe in tomatoes.

Thus, just one NIR spectrometer can replace multiple old instruments. The following were conventional methods used so far to determine maturity and ripening:

- Digital refractometer for BRIX

- Gravimetrical measurements for dry matter

- Texture analyzer for texture

- Penetrometer for firmness

Reducing Tomato Loss with NIR

There are three critical stages where tomato losses occur, and NIR tools can be used at each of them to save crops. The three steps are at the farm, during storage, and before retail.

Farm Level

Tomatoes are plucked ten to fifteen times over a season, as they ripen. Losses in vegetables at the farm level happen due to three causes:

- Harvesting too late, when the vegetables are already ripe and red. These vegetables are prone to damage during packing.

- Improper packaging, especially of soft and already ripe tomatoes, and mixing of fruits at different stages of ripeness.

- The occurrence of pests and diseases on the tomatoes can spoil them on the plant or post-harvest.

Using a Quality meter can prevent or reduce loss in two ways:

- Fix Harvest Time: Dry matter estimation by NIR can help to determine the right harvest time and be crucial in reducing losses. Tomatoes are climacteric fruits, so they can be harvested when they are mature but not yet ripe, so that they can ripen later during storage. Deciding the correct point when fruits are mature can be difficult with only sensory attributes. NIR readings provide a precise and objective measure. The crop can be tested many times as the technique is non-destructive to find the correct dry matter content.

- Sorting: Before packing, the Quality meter could be used to determine lycopene and BRIX to fix ripeness. NIR can also estimate internal and external color objectively and take the guesswork out of the process. When vegetables are mixed, ethylene produced by ripe fruits hastens the ripening of green tomatoes and shortens transport time, increasing food loss. This loss can be prevented when the vegetables are sorted according to different stages of ripeness and packed separately.

NIR absorbance by tomatoes peak at 575nm due to lycopene, and at 675nm due to chlorophyll; see Figures 1 and 2. So, as fruits ripen, there is an increase in the peak at 575nm related to lycopene and lessens at 675 nm for chlorophyll.

Middlemen Level During Sorting

There is a 10% loss of harvest because tomatoes at different stages of ripening are mixed and not sorted by farmers. They sell their produce unsorted, so the suppliers have to throw away a substantial portion of the ware they buy. The sorting done at this stage can be helped by a Quality Meter so that subsequent losses can be prevented.

Retailer

Improper sorting at earlier stages or harvesting too late can result in more losses by the time tomatoes reach the retailer. Once again, sorting or separation of damaged and good tomatoes is necessary and a Quality Meter can help.

A Win-Win Situation

Different attributes, such as dry matter at harvest time, have to be monitored and controlled to ensure efficient tomato production and reduce crop losses. Post-harvest levels of lycopene, sugars, and acidity are important parameters. Small portable NIR tools that can measure all these attributes are useful in the entire supply chain to ensure that more of the crop ultimately reaches market shelves and people’s tables. As a result, the income at each and every stage of the supply chain can improve. For society as a whole, it means resources are used sustainably, and there is less climate change and environmental degradation.

—

Vijayalaxmi Kinhal

Science Writer, CID Bio-Science

Ph.D. Ecology and Environmental Science, B.Sc Agriculture

Feature Image courtesy of Oregon State University

Sources

Acharya, U. K., Subedi, P. P., & Walsh, K. B. (2017). Robustness of Tomato Quality Evaluation Using a Portable Vis-SWNIRS for Dry Matter and Colour. International Journal of Analytical Chemistry, 2017, 1–8. doi: 10.1155/2017/2863454

Bernstad, A. K., Cánovas, A., & Valle, R. (2016). Consideration of food wastage along the supply chain in lifecycle assessments: A mini-review based on the case of tomatoes. Waste Management & Research, 35(1), 29–39. doi: 10.1177/0734242×16666945

FAO. 2011. Global food losses and food waste – Extent, causes and prevention. Rome. Retrieved from http://www.fao.org/3/a-i2697e.pdf

Hong, T., & Tsou, S. C. (1998). Determination of Tomato Quality by near Infrared Spectroscopy. Journal of Near Infrared Spectroscopy, 6(A). doi: 10.1255/jnirs.215

Radzevičius, A., Viškelis, J., Karklelienė, R., Juškevičienė, D., & Viškelis, P. (2016). Determination of tomato quality attributes using near infrared spectroscopy and reference analysis. Zemdirbyste-Agriculture, 103(1), 443–448. doi: 10.13080/z-a.2016.103.012

Saad, A., Jaiswal, P., & Jha, S. N. (2014). Non-destructive quality evaluation of intact tomato using VIS-NIR spectroscopy. International Journal of Advanced Research, 2(12), 632-639.

Saad, A., Jha, S. N., Jaiswal, P., Srivastava, N., & Helyes, L. (2016). Non-destructive quality monitoring of stored tomatoes using VIS-NIR spectroscopy. Engineering in Agriculture, Environment and Food, 9(2), 158–164. doi: 10.1016/j.eaef.2015.10.004

Related Products

- Felix Expansion Card

- F-751 Grape Quality Meter

- Custom Model Building

- F-910 AccuStore

- F-751 Melon Quality Meter

- F-751 Kiwifruit Quality Meter

- F-750 Produce Quality Meter

- F-751 Avocado Quality Meter

- F-751 Mango Quality Meter

- F-900 Portable Ethylene Analyzer

- F-950 Three Gas Analyzer

- F-920 Check It! Gas Analyzer

- F-960 Ripen It! Gas Analyzer

- F-940 Store It! Gas Analyzer

Most Popular Articles

- Spectrophotometry in 2023

- The Importance of Food Quality Testing

- NIR Applications in Agriculture – Everything…

- The 5 Most Important Parameters in Produce Quality Control

- Melon Fruit: Quality, Production & Physiology

- Fruit Respiration Impact on Fruit Quality

- Guide to Fresh Fruit Quality Control

- Liquid Spectrophotometry & Food Industry Applications

- Ethylene (C2H4) – Ripening, Crops & Agriculture

- Active Packaging: What it is and why it’s important