November 26, 2020 at 12:09 am | Updated August 29, 2022 at 9:51 pm | 7 min read

Portable devices based on near-infrared and visible light spectroscopy have revolutionized grape analysis in the vineyard, supply chain, and the processing of grape products. These new tools can be used to gather rapid and precise information on the chemical composition, nutritional value, and physiology of grapes. In this article, we provide a brief overview of the many applications of NIR spectroscopy in grape production.

Uses of Grapes

The species vitis vinifera accounts for 90% of the grapes grown globally.

Fifty percent of the grapes produced are used for making wine, thirty percent are eaten as fresh fruits, and the rest is processed to make raisins, juices, jams, etc.

Subscribe to the Felix instruments Weekly article series.

By submitting this form, you are consenting to receive marketing emails from: . You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact

The desired appearance, taste, and chemical composition of grapes will differ depending on its end-use.

Grapes meant for the table are large, attractive looking, thin-skinned, and have more pulp. Table grapes, especially the seedless varieties, have less flavor than wine grapes. Table grapes also have less sugar (about 17-19 Brix) and little acidity.

Grapes meant for winemaking are smaller. They have seeds, thicker skin, and less pulp, but contain more juice, and higher sugar (about 24-26 Brix) and acid content.

Quality Parameters in Grapes

Many chemical components in grapes are monitored. Besides the usual total soluble solids (TSS) and titratable acidity (TA) that are measured in all fruits, chemicals that give flavor are also measured. These include anthocyanin, total polyphenols, and many minerals.

Traditionally, grape samples were collected and transported to laboratories for analysis. These methods were time-consuming, expensive, and involved the use of chemicals.

Portable devices that have miniaturized near-infrared (NIR) spectroscopy are now allowing analysis to be conducted onsite from the vineyards to processing facilities.

NIR Tools

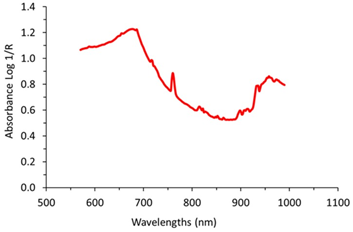

Figure 1: Spectra signature of a grape cluster, Fernández-Novales, et al., 2019. (Image credits: Molecules 2019, 24(15), 2795; https://doi.org/10.3390/molecules24152795)

NIR is the part of the light spectrum best suited for use in spectroscopy, and it is used to study the chemical composition and concentration of the various compounds. NIR interacts with the chemical bonds within compounds and helps in precise identification. Chemicals absorb, transmit, or reflect the light, and this interaction is measured by spectrometers; see Figure 1.

As NIR spectroscopy can detect a wide range of chemicals in grapes, a single, easy-to-use tool manages to replace an array of complicated laboratory procedures. Based on the results, which are obtained immediately, farmers, suppliers, and processers can make vital management decisions in real-time.

Monitoring Quality of Grapes in the Vineyard

Grapes are non-climacteric and have to ripen on the plant. Therefore, the quality of grapes at harvest is vitally important, and the ripening process is monitored throughout maturation.

The parameters measured on the go in the vineyard are the following:

- Total soluble sugars estimated by BRIX

- Titrable acidity due to lactic acid, tartaric acid, and malic acid

- Anthocyanin content and total phenols

Setting Harvest Time

The non-climacteric grapes’ quality at harvest will determine consumer satisfaction of table grapes, wine, or raisins. Visual examination alone is not precise enough to set harvest time. In this case, internal chemical analysis by NIR is a boon.

Maturity indices that are used to set harvest time are guided by the end-use of the grapes.

- Table grapes: The usual harvest parameters used for other fruits, like sugar and acidity, are also used in grapes. These measurements can be used to calculate the TSS/TA ratio or determine ripening by the sugar levels.

- Winemaking: When grapes are to be used for making wine, the levels of phenolic compounds, which contribute to aroma, can be an additional criterion. Phenols are responsible for ripening in red wines.

The position and orientation of grape clusters on a vine will influence the chemical composition of the commodity, depending on exposure to sunlight; therefore, the NIR spectra obtained from them will also differ. Using this information, farmers can identify grape bunches for early, median, and late stage harvest. This way vineyards can improve and homogenize the quality of grapes, for all purposes.

Vineyard Management

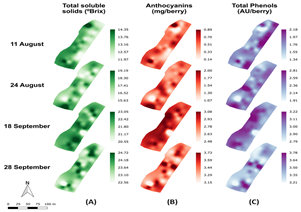

Figure 2. “Prediction maps of the spatial variability of anthocyanins (A), total soluble solids (B), and total polyphenols concentrations (C) along with the grape ripening period (11 August to 28 September),” Fernández-Novales, et al., 2019. (Image credits: Molecules 2019, 24(15), 2795; https://doi.org/10.3390/molecules24152795)

NIR tools can be used with agricultural machines to analyze the chemical composition of grapes. Based on the analysis, vineyard owners can make spatial maps of grape quality (see Figure 2) and trace this data back to variations in soil and environmental conditions within the vineyard.

For example, the effect of tillage and weeds on the growth of vines and the composition of grapes can be detected by measuring TSS, acidity, anthocyanin, and total phenol contents in grapes.

Spatial maps of the quality of grapes can guide future decisions of farmers and help them to alter their agricultural practices to optimize conditions as needed. Any vineyard can apply these precision farming techniques by using NIR tools, with minimal cash investment.

Supply Chain of Fresh Table Grapes

Since grapes will not ripen or see any further quality improvements after harvest, fresh table varieties must be transported and stored at low temperatures so that they can survive adequately for several weeks. During this time there are four uses of NIR monitoring:

- Detecting spoiled fruits: Grapes deteriorate in quality, due to the production of glycosylated compounds. The rate of release of these volatile compounds is higher in grapes that have begun to deteriorate. Glycosylated compounds can be accurately measured by NIR spectroscopy, from vineyard to retailer.

- Grading and sorting table grapes: The quality and freshness of stored grapes can be assessed by NIR. The common parameters used to judge ripeness, taste, and aroma are TSS, TSS/TA ratio, and phenolic compounds. By grading and sorting fruits, it is possible to increase consumer satisfaction.

- Price fixing: Grape prices are fixed based on quality–estimated by TSS/TA ratio, TSS, and phenolic compounds.

- Export check: Table grapes have to meet certain standards of TSS/TA ratio or TSS content for each cultivar, as specified by individual countries. These parameters are checked at the port of entry, during export, and through random checks, using NIR tools without destructive sampling. Rejected batches can be denied entry.

Raisin Production

One of the important products made from grapes, raisins are rich in fiber, carbohydrates, and minerals like copper and iron. They also have medicinal value and help in regulating blood pressure. NIR can be used to monitor these important commodities throughout the processing and end product stages.

- Processing: Raisins are made from drying grapes. NIR tools can be used to measure moisture content and water activity (aw), which increases with temperature, during the process.

- Quality control: The quality of the end product can be estimated by the chemical composition of the raisins. In this case, the quality parameters useful are bulk density, color, and moisture content.

Winemaking

NIR use in winemaking is not yet widespread, even though there are many stages where its use can be incredibly beneficial, such as

- Harvest timing: The production of quality wine starts by setting the correct time for harvest.

- Post-Harvest: Fungal diseases, especially powdery mildew, are common diseases that affect grapes. Visual examination of the large quantities harvested by machines can prove both difficult and inefficient. NIR can identify the DNA of powdery mildew and can help in maintaining the hygiene of wines.

- Processing: Wine and other alcoholic products are made by fermenting grapes with microbes. Earlier, only the alcohol content of wine was controlled during processing. Now, with the help of NIR tools, wineries can also monitor reducing sugar, pH, volatile acidity, organic acids, and sulfur dioxide in all wines—red, white, and rosa.

- Wine grading: Determination of wine quality by experienced judges and panelists is subjective. It can vary from person-to-person or day-to-day. Objective NIR estimation of the compounds, which influence the flavor and color of wines, can be used to grade wines. It also allows wineries to develop individual wine profiles.

Product Authenticity

The chemical composition of grapes is used to establish the authenticity and variety of grape products.

- Addition of external compounds: In both juice and winemaking, cheaper fruit juices can be used as adulterants or become over-diluted with water. Sugars, acids, and volatile compounds are also added to get the correct composition. NIR can detect these adulterants based on the difference in their spectra.

- Detect Varieties: It is hard to differentiate grapes of the same color. Here, the variations in chemical composition and their NIR spectra, which depend on the variety, are helpful.

-Fruits – NIR has proven its ability to differentiate between Merlot, Grenache, and Tempranillo cultivars in Spain.

-Wines – White wines, such as Riesling and Chardonnay, have been differentiated with an accuracy of 95% by NIR spectroscopy.

-Raisins – The variation of nutritional and medicinal values across different varieties of raisins influences their commercial value, so NIR can help in fixing the correct price.

The F-750 Produce Quality Meter

The F-750 Produce Quality Meter, manufactured by Felix Instruments – Applied Food Science, can non-destructively measure total soluble solids by BRIX, titrable acidity, and color. It has been tested for seedless grape varieties and has a starter model for Sultana Fresh Table Grapes. Models for other varieties can be easily created using included instructions. With simple operation and sturdy design, it is made to be used throughout the supply chain, giving stakeholders from the vineyard to the processing facility the quantitative edge they need.

—

Vijayalaxmi Kinhal

Science Writer, CID Bio-Science

Ph.D. Ecology and Environmental Science, B.Sc Agriculture

Feature image courtesy of brando

Sources

Cozzolino, D., Dambergs, R.G., Janik, L., Cynkar, W.U., & Gishen, M. (2006) “Analysis of Grapes and Wine by near Infrared Spectroscopy,” J. Near Infrared Spectrosc. 14, 279-289. Retrieved from https://www.researchgate.net/publication/244738494_Analysis_of_grapes_and_wine_by_near_infrared_spectroscopy/link/00b7d52f7fcf4d41a3000000/download

Cozzolino, D. (2015). The Role of Visible and Infrared Spectroscopy Combined with Chemometrics to Measure Phenolic Compounds in Grape and Wine Samples. Molecules, 20(1), 726-737. doi:10.3390/molecules20010726

FAO. (2016). Table and dried grapes: FAO-OIV FOCUS 2016. Retrieved from a-i7042e.pdf

Fernández-Novales, J., Tardáguila, J., Gutiérrez, S., & Paz Diago, M. (2019). On-The-Go VIS + SW – NIR Spectroscopy as a Reliable Monitoring Tool for Grape Composition within the Vineyard. Molecules (Basel, Switzerland), 24(15), 2795. https://doi.org/10.3390/molecules24152795

Feng, L., Zhu, S., Zhang, C., Bao, Y., Gao, P., & He, Y. (2018). Variety Identification of Raisins Using Near-Infrared Hyperspectral Imaging. Molecules (Basel, Switzerland), 23(11), 2907. https://doi.org/10.3390/molecules23112907

Huxsoll, C., Bolin, H., & Mackey, B. (1995). Near Infrared Analysis Potential for Grading Raisin Quality and Moisture. Journal of Food Science, 60(1), 176-180. doi:10.1111/j.1365-2621.1995.tb05632.x

Power, A., Truong, V. K., Chapman, J., & Cozzolino, D. (2019). From the Laboratory to The Vineyard—Evolution of The Measurement of Grape Composition using NIR Spectroscopy towards High-Throughput Analysis. High-Throughput, 8(4), 21. doi:10.3390/ht8040021

Puckette, M. (2012, October 10). Cultivation: Table Grapes vs. Wine Grapes. Retrieved from https://winefolly.com/tips/table-grapes-vs-wine-grapes/

Xiao, H., Feng, L., Song, D., Tu, K., Peng, J., & Pan, L. (2019). Grading and Sorting of Grape Berries Using Visible-Near Infrared Spectroscopy on the Basis of Multiple Inner Quality Parameters. Sensors, 19(11), 2600. doi:10.3390/s19112600

Related Products

- F-751 Grape Quality Meter

- Custom Model Building

- F-910 AccuStore

- F-751 Melon Quality Meter

- F-751 Kiwifruit Quality Meter

- F-750 Produce Quality Meter

- F-751 Avocado Quality Meter

- F-751 Mango Quality Meter

- F-900 Portable Ethylene Analyzer

- F-950 Three Gas Analyzer

- F-920 Check It! Gas Analyzer

- F-960 Ripen It! Gas Analyzer

- F-940 Store It! Gas Analyzer

Most Popular Articles

- Spectrophotometry in 2023

- The Importance of Food Quality Testing

- NIR Applications in Agriculture – Everything…

- The 5 Most Important Parameters in Produce Quality Control

- Melon Fruit: Quality, Production & Physiology

- Fruit Respiration Impact on Fruit Quality

- Guide to Fresh Fruit Quality Control

- Liquid Spectrophotometry & Food Industry Applications

- Ethylene (C2H4) – Ripening, Crops & Agriculture

- Active Packaging: What it is and why it’s important