September 10, 2020 at 2:39 am | Updated September 10, 2020 at 2:39 am | 6 min read

Near-infrared spectroscopy’s application in agricultural and food production is well established. Given its proven abilities to monitor chemical composition qualitatively and quantitatively, it is being used inline and online in the production of several organic compounds. Some of the early users of near-infrared spectroscopy in the chemical industry are producers of pharmaceuticals, resins, amino acids, and solvents.

NIR Spectroscopy

Spectroscopy is the interaction of light with matter and its subsequent emission, transmission, and reflectance. The wavelength that compounds react to depends on their chemical composition.

The infrared wavelengths, especially the near-infrared (NIR) range of the light spectra, reacts best with organic compounds. NIR occurs next to the red color in visible light and falls within the range of 800 to 2,500 nanometers (nm).

Subscribe to the Felix instruments Weekly article series.

By submitting this form, you are consenting to receive marketing emails from: . You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact

The NIR reacts with the vibrational energy of the N-O, C-H, N-H, and S-H bonds within compounds. Hence, NIR spectroscopy (NIRS) is useful for all compounds that contain hydrogen (H). The interaction is used to identify compounds and also estimate their quantities.

One of the main sectors where NIRS is applied is the agricultural and food industry. It is used to control the quality of various food products. Nowadays, it is also used in the processing of fruits and vegetables, cheese production, wineries, etc.

Advantages of NIRS

NIRS is popular for the following reasons:

- It is non-destructive.

- It makes rapid analyses and gives results within seconds.

- Several compounds can be simultaneously measured with just one technology.

- There is no need to get pure extracts of the components being analyzed.

- It doesn’t use chemicals, so it is not hazardous and is also environmentally friendly.

- It can be used with intact samples or processed material in fluid and solid forms.

All these aspects have made it ideal for use both inline and online in a processing unit.

Several other products, besides food, are also made of organic compounds. Scientists are exploring the possibilities of extending the application of NIRS in all of these sectors.

In 2004, the Food and Drug Administration (FDA) in the USA suggested the use of the Process Analytical Technology (PAT) for the pharmaceutical industry. Monitoring quality and controlling the manufacturing process with timely critical analysis of relevant parameters of the raw materials, ingredients, process, and final product was one of the main recommendations that the FDA made.

Manufacture of Medicines

.png)

Figure 1. Integrating NIRS in PAT. Wenlong et al 2016. (Image credits: Sensors and Actuators B: Chemical Volume 231, August 2016, Pages 313-323. https://doi.org/10.1016/j.snb.2016.03.023)

Chinese traditional medicines are produced using the batch process since smaller quantities of the final product are needed. Scientists have tested a method that integrates NIRS for multivariate tests, which test many factors at the same time, to monitor the process.

NIRS was used for the real-time monitoring of material evaluations, production process, and end product. Figure 1 shows how it was used in one such case. Scientists found that this method and setup was useful to also diagnose failed batches, providing feedback on the production process.

Synthesis of Amino Acids

Twenty amino acids are used by all living things to make the proteins they need. Plants can produce them all. However, people can produce only ten of them and are dependent on plant and animal sources to get the other ten essential building blocks. Since the amino acids can’t be stored by the body, we need a constant supply every day for our nutrition and health.

Fifteen amino acids are produced by industries and used for several purposes, such as food additives, flavoring agents, ingredients in cosmetics and medicines, specialty nutrients in transfusions, etc. The amino acids are produced by hydrolysis, chemical, or microbial methods.

Cornu Bubali (water buffalo horn) has amino acids, which are used in Traditional Chinese Medicine. These are extracted by hydrolysis. NIRS has been used successfully to monitor the amino acid concentration profile during the whole process. Concentrations of l-phenylalanine, l-proline, l-valine, l-tyrosine, and l-lysine were predicted with accuracy.

Biological sources like Cornu Bubali are rare, and the extraction processes are necessarily small. Therefore, producers need to keep a close watch on the process to ensure a good recovery.

Extraction of Active Pharmaceutical Ingredients

NIRS has various uses in the production of active pharmaceutical ingredients to monitor concentrations and quality.

Concentrations

Citri reticulatae pericarpium, or orange peel, is used in thousands of Chinese Traditional Medicine preparations. It contains more than a hundred compounds that could be active ingredients. Of them, hesperidin and nobiletin are used as quantitative indicators. These two compounds were identified and the quantities were estimated accurately in real-time by using online NIRS. So, producers could be assured of the amounts of medicine they were recovering.

Quality

Gingko biloba has been used as a medicinal plant since ancient times. The Ginko biloba extracts, which are used as raw materials in many modern pharmaceutical products, can vary in quality. The variation in quality is unpredictable and can’t be controlled. On the other hand, its quality can influence the manufacture of medicines in which it is an ingredient, and it is done through granulation and compression.

Most conventional methods have been ineffective in the quality control of Ginko biloba extracts. Out of several methods that were tested, NIRS was found to be sensitive to the quality difference and could estimate the parameters accurately. Therefore, it has been recommended for use in PAT for Ginko biloba extraction to

- quantitively establish the source of variation,

- test final product quality,

- and control the manufacturing process.

Synthesis of Industrial Ingredients

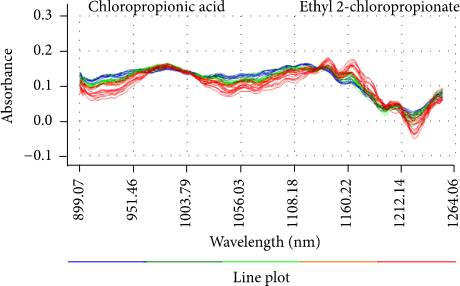

Figure 2: “Origin NIR spectra of the synthesis process of ethyl 2-chloropropionate,” Zhang et al. 2015. (Image credits: https://www.hindawi.com/journals/ijac/2015/145315/fig5/)

The chemical 2-chloropropionate is an important chemical intermediary and reagent. It is used in the manufacture of herbicides, amino acids, anti-inflammatory drugs, etc.

It is synthesized by a process that is catalyzed by ion exchange resin, and the process itself is considered to be simple. Its methods of analysis were more of a problem offline as they didn’t meet the requirements of producers and the industry.

Earlier offline gas chromatography was used for the tests that NIRS replaced. Scientists found that NIRS analysis predictions of the concentrations of the chemicals’ matched those of gas chromatography. The advantage of the NIRS method was that it was tried online, so results were obtained in real-time to help the process without delay.

Production of Solvents

Methyl isobutyl ketone (MIBK) is a natural compound found in food. It is used as a food flavoring agent, an industrial solvent, a cosmetic solvent, a fragrance, and an excipient in drugs to stabilize them.

MIBK is commonly produced in factories from acetone. NIRS was used to analyze the results of various operating conditions on the production process and their influence on the final yield that could be recovered. The conditions tested were the following:

- Temperature

- Pressure

- Feed rate

- Hydrogen to acetone molar ratio

The steps tested were MIBK selectivity and productivity. By integrating NIRS inline in the PAT process, the tests and analyses could be conducted in real-time, and scientists were able to show that higher pressure and feed rate could improve productivity by 30% for MIBK.

Thus, scientists were able to show the conditions that could optimize MIBK production. In addition, they have shown how to integrate NIRS to monitor the production process.

NIRS Tools

There are several NIRS tools on the market that have miniaturized the complex spectroscopic technology into small devices. Some are portable, like those from Felix Instruments Applied Food Science for agricultural products. Others are made specifically to suit the needs of other industries. All of them share the characteristics that they are objective, precise, handy, fast, and reliable for use in monitoring the quality of either products or processes.

—

Vijayalaxmi Kinhal

Science Writer, CID Bio-Science

Ph.D. Ecology and Environmental Science, B.Sc Agriculture

Feature image courtesy of Grey World

Sources

Dayhoff, M.O. (2003, September 30). The Chemistry of Amino Acids. Retrieved from http://www.biology.arizona.edu/biochemistry/problem_sets/aa/aa.html

IARC Working Group on the Evaluation of Carcinogenic Risks to Humans. (2013). Some Chemicals Present in Industrial and Consumer Products, Food and Drinking-Water. Lyon (FR): International Agency for Research on Cancer; 2013. (IARC Monographs on the Evaluation of Carcinogenic Risks to Humans, No. 101.) METHYL ISOBUTYL KETONE. Retrieved from https://www.ncbi.nlm.nih.gov/books/NBK373195/

Ivanov, K., Stoimenova, A., Obreshkova, D., & Saso, L. (2013) Biotechnology in the Production of Pharmaceutical Industry Ingredients: Amino Acids, Biotechnology & Biotechnological Equipment, 27:2, 3620-3626, DOI: 10.5504/BBEQ.2012.0134

Ma, L., Peng, Y., Pei, Y. et al. (2019). Systematic discovery about NIR spectral assignment from chemical structural property to natural chemical compounds. Sci Rep 9, 9503. https://doi.org/10.1038/s41598-019-45945-y

Prinsloo, N.M., Engelbrecht, J. P., Mashapa, T. N., & Strauss, M. J. (2008). “Acetone to MIBK process optimization through multidisciplinary chemometrics and in-line NIR spectroscopy,” Applied Catalysis A: General, 344, 20–29. https://doi.org/10.1016/j.apcata.2008.03.041

Rosa, S.S., Barata, P.A., Martins, J.M, & Menezes, J.C. (2008). Near-infrared reflectance spectroscopy as a process analytical technology tool in Ginkgo biloba extract qualification. Journal of Pharmaceutical and Biomedical Analysis, 47(2):320-327. DOI: 10.1016/j.jpba.2008.01.031.

U.S. Department of Health and Human Services, Food, and Drug Administration. (2004). Guidance for Industry: PAT—A Framework for Innovative Pharmaceutical Development, Manufacturing and Quality Assurance, U.S. Department of Health and Human Services, FDA. Retrieved from https://www.fda.gov/media/71012/download

Wenlong, L., Han, H., Cheng, Z., Zhang, Y., Liu, S., Qu, H. (2016). A feasibility research on the monitoring of traditional Chinese medicine production process using NIR-based multivariate process trajectories. Sensors and Actuators B: Chemical, 231, 313-323. https://doi.org/10.1016/j.snb.2016.03.023

Wu, Z., Peng, Y.F., W. Chen, W., et al. (2013). “NIR spectroscopy as a process analytical technology (PAT) tool for monitoring and understanding of a hydrolysis process,” Bioresource Technology, 137, 394–399. https://doi.org/10.1016/j.biortech.2013.03.008

Yu, X., Sun, S., Guo, Y., Liu, Y., Yang, D., Li, G., & Lü, S. (2018). Citri Reticulatae Pericarpium (Chenpi): Botany, ethnopharmacology, phytochemistry, and pharmacology of a frequently used traditional Chinese medicine. Ethnopharmacology, 220 (28), 265-282. https://doi.org/10.1016/j.jep.2018.03.031

Zhang, W., Song, H., Lu, J., Liu, W., Nie, L., & Yao, S. (2015). Online NIR Analysis and Prediction Model for Synthesis Process of Ethyl 2-Chloropropionate. International Journal of Analytical Chemistry. https://doi.org/10.1155/2015/145315

Zhou, Z. et al. (2016). Comparison of Ensemble Strategies in Online NIR for Monitoring the Extraction Process of Pericarpium Citri Reticulatae Based on Different Variable Selections. Planta medica, 82, 154–162, https://doi.org/10.1055/s-0035-1558085

Related Products

- F-751 Grape Quality Meter

- Custom Model Building

- F-901 AccuRipe & AccuStore

- F-751 Melon Quality Meter

- F-751 Kiwifruit Quality Meter

- F-750 Produce Quality Meter

- F-751 Avocado Quality Meter

- F-751 Mango Quality Meter

- F-900 Portable Ethylene Analyzer

- F-950 Three Gas Analyzer

- F-920 Check It! Gas Analyzer

- F-960 Ripen It! Gas Analyzer

- F-940 Store It! Gas Analyzer

Most Popular Articles

- Spectrophotometry in 2023

- The Importance of Food Quality Testing

- NIR Applications in Agriculture – Everything…

- The 5 Most Important Parameters in Produce Quality Control

- Melon Fruit: Quality, Production & Physiology

- Guide to Fresh Fruit Quality Control

- Liquid Spectrophotometry & Food Industry Applications

- Ethylene (C2H4) – Ripening, Crops & Agriculture

- Fruit Respiration Impact on Fruit Quality

- Active Packaging: What it is and why it’s important