April 13, 2021 at 9:32 pm | Updated April 13, 2021 at 9:32 pm | 6 min read

Controlling postharvest degreening in pepper fruits has several benefits for suppliers. It can enhance customer acceptance, fruit quality, and can reduce weight loss. Understanding the biochemistry of treatments during chlorophyll degradation can help food scientists make more accurate recommendations to maintain postharvest pepper fruit quality. For this, food scientists used precise carbon dioxide measurement devices for quick and reliable results.

Degreening in Peppers

Green peppers (Capsicum annuum L.) are a popular vegetable and also have high nutritional value. However, they have a short shelf life due to internal biochemical and physiological changes, such as color change, water content loss, and disease. These are changes that occur in the supply chain postharvest, causing loss of yield, loss of profits, and food loss and waste.

Color and firmness are criteria used by customers to judge the quality of any vegetables. Green pepper fruits can lose their color due to fruit ripening, microbial infection, or damage. Chlorophyll, which is responsible for the green color, degrades due to complex enzymatic processes. The various chemical reactions and enzymes involved are well documented.

Subscribe to the Felix instruments Weekly article series.

By submitting this form, you are consenting to receive marketing emails from: . You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact

Inhibitors Control Chlorophyll Degradation

Building on available knowledge, a team of Chinese food scientists—Du, Jin, Zhao, Han, Sun, Chen, Yue, Luo, and Fu—decided to test a few chemical inhibitors that are widely used for other vegetables and fruits. A few previous studies show some are effective in controlling degreening, but the regulatory roles in the chlorophyll degradation pathway were unknown.

The food scientists tested the following chemicals:

- 1-Methylcyclopropene (1-MCP), which slows chlorophyll degradation by inhibiting chlorophyllase activity by controlling the genes that express this enzyme.

- Chlorine dioxide (ClO2), which is a safe and effective disinfectant that works against microorganisms. Moreover, it reduces fruit respiration and decay, and it maintains ascorbic acid and chlorophyll levels to keep peppers healthy and green.

They decided to trace the effects of treatments with 1-MCP or ClO2 alone and also when combined on pepper fruits.

The scientists took pepper fruit samples at a mature stage, twenty-five days after flowering, that had similar size and color. There was no indication, visually, of any infection in any of the samples. The food scientists then measured the firmness and soluble solids content (SSC) of all pepper fruits.

There were 300 pepper fruits in each of the four groups: control, treated by 1 μL L−1 1-MCP, treated by 30 μL L−1 CIO2, and treated by 1-MCP and ClO2. For storage, the pepper fruits were sub-divided into groups of twenty in punctured polyethylene bags at 20°C and 85 ± 5 % RH.

Testing Respiration with a CO2 Measurement Device

Fifteen pepper fruits, randomly chosen from each group, were examined after 0, 3, 6, 9, and 12 days of storage.

The parameters tested were weight loss, firmness, TSS, and ascorbic acid levels. The only physiological function tested in the pepper fruits was respiration. Too much carbon dioxide produced by respiration can hasten fruit decay, so the food scientists used a carbon dioxide measurement device, the F-920 Check It! Gas Analyzer.

The instrument, manufactured by Felix Instruments – Applied Food Science, is designed to measure headspace gases in closed commercial modified atmosphere packaging. This feature suited the food scientists, who wanted to measure carbon dioxide production in closed containers.

The food scientists placed 15 green pepper fruit in 10 L sealed containers for an hour at 20°C. The tool comes with accessories, such as injection needles, and tube accessory kits that help in the collection of even small quantities of gas produced. The lower detection limit is 0.01% of gas. The carbon dioxide measurement device, F-920, measures CO2 and O2 levels up to 100%. Each reading, displayed digitally, is recorded within six seconds. Up to 8000 readings can be stored in the data logger and transferred using a USB port.

Chemical Treatments Control Chlorophyll Degradation

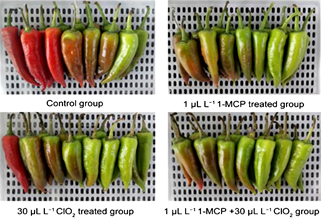

Figure 1. “Color phenotype of green pepper fruit in the control group and 1-MCP, ClO2, 1-MCP + ClO2 treatment after storage at 20 °C for 12 d,” Du et al, 2021. (Image credits:https://doi.org/10.1016/j.postharvbio.2020.111363)

The food scientists found that the amount of chlorophyll decreased over time, as part of the fruit ripening process. As the levels of chlorophyll decreased, there was a simultaneous increase in carotenoid levels.

After 12 days, it was evident that all three treatments were successful in controlling chlorophyll degradation. Pepper fruits treated with 1-MCP, ClO2, and a combination (1-MCP + ClO2) had a reddening index of 52.8%, 56.8%, and 41.2%, respectively, while the control had 83.1%; see Figure 1. The combination of the two chemicals clearly produced better results than either of them alone.

The food scientists also found evidence of climacteric respiration in the pepper fruit. Usually, only climacteric fruits show increased respiration during fruit ripening, so the Chinese research team made a bonus discovery.

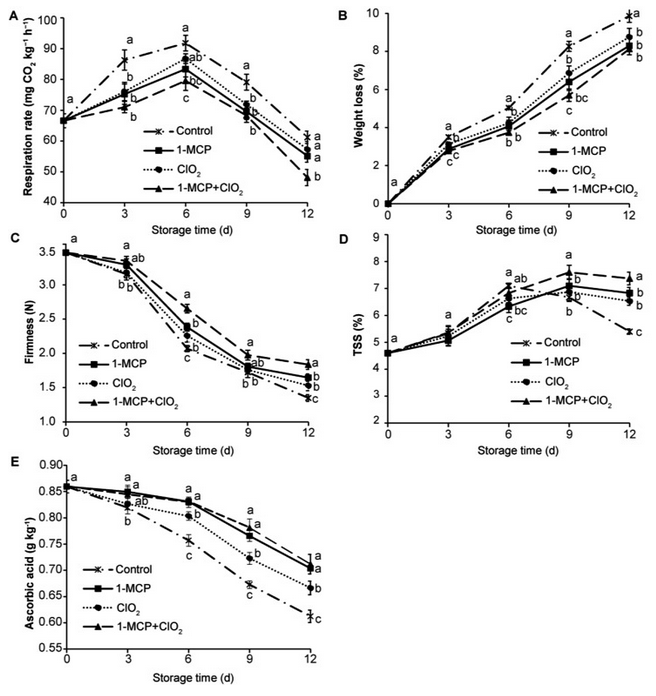

Though the highest respiration was found in control without any treatments, the trend was the same in all four groups. The respiration rate rose until the sixth day, after which it declined in all four groups. There was a significant difference in respiration rate after 12 days between the control and the combination treatment (1-MCP + ClO2). Thus, only the combination treatment was successful in preventing quality decline due to respiration in pepper fruits.

Figure 2: “Changes in respiration rate (A), weight loss (B), firmness (C), total soluble solids (TSS, D) and ascorbic acid (E) of green pepper fruit after treatment with 1 μL L−1 1-MCP, 30 μL L−1 ClO2 and 1 μL L−1 1-MCP+30 μL L−1 ClO2 during storage at 20°C for 12 d,” Du et al, 2021. (Image credits: https://doi.org/10.1016/j.postharvbio.2020.111363 )

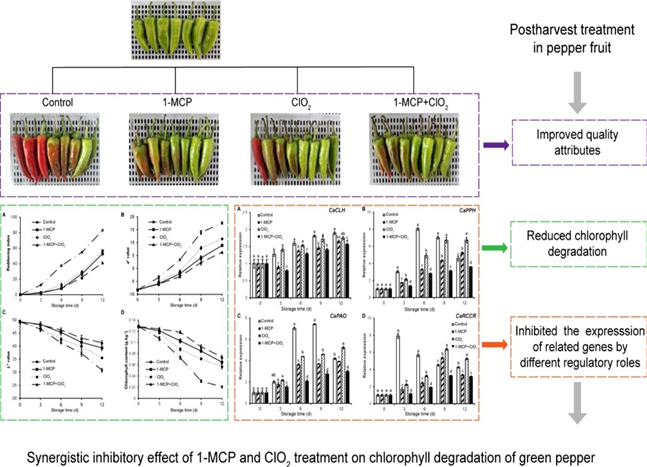

To study how the treatments were controlling chlorophyll degradation, the food scientists used the qRT-PCR method to analyze the expression of the following four genes in all of the treatments: CaCLH, CaPPH, CaPAO, and CaRCCR.

1-MCP, ClO2, and the combination (1-MCP + ClO2) all reduced the expression of CaPPH, CaPAO, and CaRCCR, helping to delay chlorophyll degradation.

The two treatments differed in the effect they had on the CaCLH gene expression. This gene, which causes chlorophyll degradation, increases during storage. ClO2 had no impact on the gene. However, 1-MCP and 1-MCP + ClO2 suppressed CaCLH expression significantly. This shows that the two treatments have differing roles in chlorophyll degradation.

Figure 3: Tracing the effect of the three treatments1 μL L−1 1-MCP, 30 μL L−1 ClO2, and 1 μL L−1 1-MCP+30 μL L−1 ClO2 on color change and gene expression of chlorophyll degradation, Du et al, 2021. (Image credits: https://doi.org/10.1016/j.postharvbio.2020.111363 )

Thus, the scientists found that treating pepper fruits with 1-MCP, ClO2, and the combination (1-MCP + ClO2) could significantly control color change, reduce weight loss, and maintain firmness, TSS, and ascorbic acid levels. Since they found that the two treatments have differing impacts on the molecular level, they decided it was best to use a combination of both, even though they can be effective alone in reducing chlorophyll degradation.

Probing Internal Physiology

Since all three treatments were effective in controlling degreening, one of the two treatments, 1-MCP or ClO2, could have been recommended. However, probing physiology and checking gene expression allowed the scientists to confirm that a combination was a better choice. Carbon dioxide measurement devices, such as the F-920, allow an accurate estimation of the gas and help with shedding light on complex internal pepper fruit functioning. The study was groundbreaking, as it showed climacteric respiration in non-climacteric pepper fruits. Now, the food supply industry also knows when to expect the most respiration and can adjust storage conditions to get better control of pepper fruit quality. As a result, there will be less food loss and waste.

—

Vijayalaxmi Kinhal

Science Writer, CID Bio-Science

Ph.D. Ecology and Environmental Science, B.Sc Agriculture

Feature photo courtesy of Obed Hernández

Sources

Du, Y., Jin, T., Zhao, H., Han, C., Sun, F., Chen, Q., . . . Fu, M. (2021). Synergistic inhibitory effect OF 1-methylcyclopropene (1-MCP) and chlorine dioxide (ClO2) treatment on CHLOROPHYLL degradation of green pepper fruit during storage. Postharvest Biology and Technology, 171, 111363. doi:10.1016/j.postharvbio.2020.111363

FAO. (n.d.). Prevention of post-harvest food losses fruits, vegetables and root crops a training manual – pre-harvest factors in produce marketing-perishability and produce losses-cont. Retrieved, from http://www.fao.org/3/T0073E/T0073E02.htm#:~:text=Respiration%20rate%20slows%20gradually%20during%20growth%20and%20after%20harvest.&text=The%20start%20of%20ripening%20is,and%20develops%20good%20eating%20quality.

Related Products

- F-751 Grape Quality Meter

- Custom Model Building

- F-910 AccuStore

- F-751 Melon Quality Meter

- F-751 Kiwifruit Quality Meter

- F-750 Produce Quality Meter

- F-751 Avocado Quality Meter

- F-751 Mango Quality Meter

- F-900 Portable Ethylene Analyzer

- F-950 Three Gas Analyzer

- F-920 Check It! Gas Analyzer

- F-960 Ripen It! Gas Analyzer

- F-940 Store It! Gas Analyzer

Most Popular Articles

- Spectrophotometry in 2023

- The Importance of Food Quality Testing

- NIR Applications in Agriculture – Everything…

- The 5 Most Important Parameters in Produce Quality Control

- Melon Fruit: Quality, Production & Physiology

- Fruit Respiration Impact on Fruit Quality

- Guide to Fresh Fruit Quality Control

- Liquid Spectrophotometry & Food Industry Applications

- Ethylene (C2H4) – Ripening, Crops & Agriculture

- Active Packaging: What it is and why it’s important