July 21, 2025 at 5:19 pm | Updated July 21, 2025 at 5:55 pm | 8 min read

- Avocados are challenging due to their unique ripening process, which requires a few days post-harvest to overcome the “tree factor.”

- The leading causes of quality problems are incorrect maturity at harvest, careless handling, and improper storage temperatures and gas mixtures in cool storage.

- Limiting problems starts with harvesting avocados at the correct maturity and quality monitoring throughout the supply chain to spot problems as early as possible.

Avocados are a highly priced tropical fruit. Their cultivation has increased, driven by a strong global demand for conventional and organic fruits. However, substantial postharvest food losses of 23-40% can reduce profits and create bottlenecks in the supply chain. To limit these losses, stakeholders can monitor the fruit quality to detect problems as soon as possible. In this article, you will find the common avocado quality problems faced in the supply chain.

Avocado Supply Chain

Avocados are grown and exported from tropical countries like Mexico, Colombia, Peru, the Dominican Republic, Kenya, the USA, Indonesia, Brazil, New Zealand, etc. Due to their flavor and nutritional value, the fruits are exported to North America, Europe, and the Asia-Pacific regions. The global market for avocados was $15,548.2 million in 2024 and is expected to grow at a compound annual growth rate (CAGR) of 9.7% until 2031.

Avocados are climacteric and harvested when mature but not ripe. The unique feature of the avocado is that it will not ripen until it is off the tree. After ripening, avocados have a short shelf life. The supply chain stages for avocados are as follows:

Subscribe to the Felix instruments Weekly article series.

By submitting this form, you are consenting to receive marketing emails from: . You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact

- Farms: The picking time is determined using harvest maturity indices to ensure the fruits receive a good start in the supply chain.

- Packing houses are typically situated close to farms to minimize transport damage and facilitate early precooling. The avocados are graded, sorted, and packed according to their maturity. The fruits are packed and loaded onto refrigerated trucks.

- Transport, storage, and distribution: These phases require a closed cold chain to control ripening until the product reaches retail.

Avocados can develop several problems during the extended supply chain for both domestic and export markets, including bruising, suboptimal temperature and humidity, and microbial spoilage. These problems can compromise quality and safety, reduce consumer appeal, and shorten shelf life, so they must be detected promptly. Suppliers check for defects through manual checks or by using instruments, which can be destructive or non-destructive.

The fruit industry is increasingly using non-destructive detection of fruit quality through near-infrared (NIR) spectroscopy due to its many advantages. NIR spectrometers, such as the F-751 Avocado Quality Meter from Felix Instruments Applied Food Sciences, are precise and provide analysis results in real-time, eliminating the need to destroy fruits for sampling and the time required for lengthy and complicated laboratory procedures.

The quality problems in texture, appearance, flavor, and ripening are discussed below.

Fruit Texture

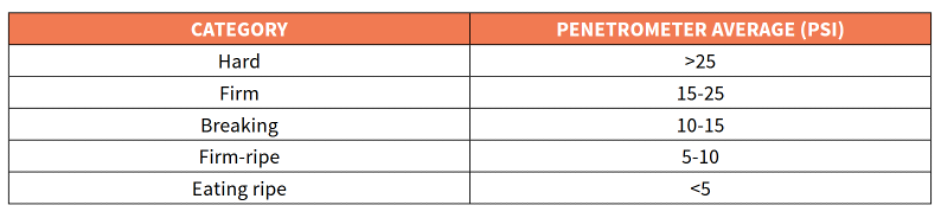

Like other fruits, avocados get softer after ripening. To check if fruits have the correct texture, people use hand pressure or destructive sampling with penetrometers. For avocados, penetrometers need a 1/4-inch or 6-mm tip. Softness is checked around the fruit equator. Several fruits in a batch are checked to get the average value. Table 1 shows the varying firmness of Hass avocados during fruit development.

Table 1: Avocado softness category, Hass-Avocado-Board. (Credits: https://hassavocadoboard.com/wp-content/uploads/Hass-Avocado-Board-07-Common-Fruit-Defects.pdf)

External Fruit Quality

External appearance is the primary parameter consumers use to estimate quality, ripeness, and safety, so stakeholders attempt to optimize these attributes.

- Skin color: The supply chain uses external fruit color to estimate readiness and marketability, as consumers use the peel to choose avocados. Avocados are black to dark green when ripe. However, the color formation depends on cultivar, maturity, season, climate, and place of origin.

- Defects: A quality and safe fruit should have few or no defects. In the supply chain, stakeholders classify fruits on a 0-10 scale based on the percentage of skin affected. A score of 1 indicates a 10% defect, and a score of 10 means that 100% of the skin has defects.

Types of External Defects

The various defects that suppliers must look out for are as follows:

Ridging: Ridges are raised portions usually running longitudinally down the fruit. They are formed due to damage during early fruit development, adverse weather conditions, or insect infestations. These fruit areas are prone to further damage during handling and can spoil the fruit’s appeal to customers, though internal quality is not affected.

Sunburn: Hard, cracked, or corky patches that are yellow to brown or black can develop on avocado skin due to sunburn. The fruit pulp under the affected skin is also damaged and doesn’t ripen normally. Fruit from the top of the tree is more prone to this damage.

Lenticel damage: Lenticels are pores on the fruit skin that facilitate gas exchange, and they can collapse and become dark due to abrasion during handling or a fall, followed by extended cool storage. Initial damage around lenticels worsens due to cell dehydration, leading to collapse and darkening. The internal quality of fruits is not affected. Fruits turgid at harvest are prone to lenticel damage.

Chilling injury: Storing and transporting avocados at very low temperatures can cause chilling damage, characterized by the development of sunken, black lesions on the skin. Extreme chilling injury can also affect the internal quality of the fruit. Fruits that are not fully mature and those from trees with high nitrogen and low calcium are prone to this problem. Cold injury worsens with more extended periods of storage and lower temperatures.

Thrip damage: Thrips can remove the top layer of skin during early fruit development. The scar tissue is brown, corky, and rough, and it expands in the area as the fruit grows. This area doesn’t change color during ripening, but internal quality is unaffected.

Scarring: Brown, corky, rough scars in lines can occur during early fruit development due to physical damage from leaves or branches. It is a cosmetic problem with no effect on internal quality.

Copper sulfate residue: Copper sulfate, a standard fungicide spray used in orchards, leaves blue-green residues on the fruits that consumers do not accept, even though it is not a food safety issue.

Manual checks can identify these external problems. For large packinghouses, non-destructive NIR spectrometers installed either inline or online can help identify issues based on discoloration for culling purposes.

Internal Defects

Avocados can also develop internal defects due to storage conditions, handling, pests, and diseases. The common problems are listed below.

Figure 1: Internal discoloration due to bruising, Hass Avocado Board. (Image credits: https://hassavocadoboard.com/wp-content/uploads/Hass-Avocado-Board-07-Common-Fruit-Defects.pdf)

Bruising: Before ripening, the effects of rough handling, dropping during harvests, and impacts or bouncing during packaging are not visible. However, with ripening, the injured area in the fruit flesh turns brown to black (see Figure 1). Symptom severity depends on the height of the fall, the stage of ripeness, and temperature. Careful handling, use of pads and baffles in packs, strong pallets for transportation, and maintenance of cool temperatures can reduce these effects.

Diffuse flesh discoloration: Internal chilling injury, incorrect gas mixtures in controlled atmosphere storage, or prolonged shipping periods can cause diffuse discoloration of the fruit flesh to appear grey, brown, or black, due to the presence of dead tissue. As ripening proceeds, these parts of the fruit have poor eating quality.

Grey pulp: When the diffuse discoloration becomes intense, most of the flesh becomes grey and is associated with vascular discoloration, usually starting from the bottom of the fruit to reach the stem end. More mature fruits harvested later in the season, with longer storage times and warmer storage temperatures, initiate the ripening process, producing this effect.

Flesh adhering to the seed: Uneven ripening can cause the unripe portion of the flesh to adhere to the seed when cut. Early-season fruits that are less mature or those that experience improper ripening temperatures can cause this problem, which affects fruit quality.

Stem-end rot: Rot starts at the stem end and is caused by several fungi, such as Fusicoccum aesculin and Lapsiodiplodia theobromae. First, the skin near the stem end becomes dark; then, the fruit flesh turns brown. As the rot progresses, vascular browning could start. Stem rot can start during fruit development or at harvest, and wet and warm conditions can exacerbate the issue. Postharvest fungicides cannot completely control it, but lower temperatures are more successful.

Vascular browning: The vascular tissue begins to turn dark brown, starting from the stem and extending to the distal end. It can occur due to internal chilling damage after extended cool storage, or pathogens can cause it, and it often happens with stem end rot.

People use manual checks of 10 fruit samples to report defects on a percentage basis. NIR-spectroscopy-based instruments can non-destructively detect internal defects by identifying discoloration before external symptoms are visible. This provides stakeholders with ample advance notice to take specific and timely corrective action.

Ripening Problems

Avocado fruits suffer from various kinds of ripening problems, including slow, fast, premature, and uneven.

Uneven ripening: Fruits can be at different stages of ripening in a single pallet or between pallets in a batch. Uneven ripening occurs because fruits were harvested at varying maturity, there are temperature differences after harvest during packing, or there is insufficient airflow during storage. Avoiding the mixing of fruits harvested on different days, from diverse orchards, or held at varying postharvest storage temperatures can reduce these problems.

Slow ripening: Avocados need more than seven days to overcome the “tree factor” to begin ripening. Slow ripening occurs when ethylene treatment is initiated too early, the tree factor is not overcome, and the fruit is immature. Other factors that can affect ripening include low temperatures in ripening rooms, carbon dioxide levels exceeding 1%, and disrupted ethylene flow.

Premature ripening: Avocados can start to ripen prematurely while still in cool storage. This occurs when precooling is delayed before packing, airflow between storage pallets is insufficient, leading to high ethylene concentrations of over 5%, and poor temperature management.

Checkerboard ripening: When a box of avocados ripens at varying rates, the fruit colors range from green to black and exhibit different levels of softness. Although internal quality is not affected, it is challenging for suppliers to accurately predict ripening and shelf life, which can result in food loss. Packing fruits harvested at varying maturity together can cause this problem.

Poor skin color: Sometimes, fruits start to soften without developing the associated dark color. Avocados picked early with low to minimal dry matter and cooler ripening temperatures can cause this effect.

Poor flavor development: Avocados have a watery flavor that falls short of consumer satisfaction. Fruits harvested with low oil content and dry matter content, and that are not completely mature, will have a poor taste.

Short retail shelf life: In this case, avocados are often overripe at retailers and can’t be held for many days. Fruits stored too long before ripening, or the occurrence of higher temperatures than necessary during ripening or storage, can cause this problem. To solve this problem, sell avocados within five days of ripening.

To avoid the problems of untimely ripening, poor quality, and taste at retailers, ensure proper maturity at harvest, measured in terms of the prescribed dry matter percentage for each cultivar in its respective region. The dry matter requirements for the same cultivar can vary in different countries,

Saving Avocado Crops

Suppliers must detect fruit with problems as soon as possible to cull them and limit losses due to rejection by retailers and end consumers. Using either portable or fixed NIR-based spectrometers, stakeholders can check external and internal color for damage. Instruments like the F-751 Avocado Quality Meter can be used by farms, retailers, and others to check for color and dry matter content, thereby avoiding fruit losses at each stage of the supply chain. It can also help facilities with a labor shortage, as NIR spectrometers save labor and time. Timely quality checks can increase ROI for all stakeholders.

Find out more about the F-751 Avocado Quality Meter and how we can help your avocado business.

Sources

Cognitive Market Research. (2025). Avocado Market Report 2025 (Global Edition). Retrieved from https://www.cognitivemarketresearch.com/avocado-market-report?campaign_source=google_ads&campaign_name=CMR_EU_DSA01&gad_source=1&gad_campaignid=22119250923&gclid=CjwKCAjwpMTCBhA-EiwA_-MsmcVb6lxwh4TKczxTkHkIaT-eF5J05yntoDsNDARSqAIEbP-vYV8KyxoCJ8QQAvD_BwE

Joyce, D., Wells, I., Ainsworth, N., Hofman, P., Coates, L., and Newett, S. (2018). Avocado fruit Quality Problem Solver. Retrieved from https://avocado.org.au/wp-content/uploads/2018/05/Avocado-Fruit-Quality-Problem-Solver.pdf

Hass-Avocado-Board. (n.d.). Common Fruit Defects 07- A Guide to Best Practices. Retrieved from https://hassavocadoboard.com/wp-content/uploads/Hass-Avocado-Board-07-Common-Fruit-Defects.pdf

Olivares, D., Ulloa, P. A., Vergara, C., Hernández, I., García-Rojas, M. Á., Campos-Vargas, R., Pedreschi, R., & Defilippi, B. G. (2024). Effects of Delaying the Storage of ‘Hass’ Avocados under a Controlled Atmosphere on Skin Color, Bioactive Compounds and Antioxidant Capacity. Plants, 13(11), 1455. https://doi.org/10.3390/plants13111455

WUR. (n.d.). The avocado supply chain. Retrieved at https://www.freshknowledge.eu/en/increase-your-knowledge/crops/avocado/the-avocado-supply-chain.htm

Related Products

- F-751 Grape Quality Meter

- Custom Model Building

- F-910 AccuStore

- F-751 Melon Quality Meter

- F-751 Kiwifruit Quality Meter

- F-750 Produce Quality Meter

- F-751 Avocado Quality Meter

- F-751 Mango Quality Meter

- F-900 Portable Ethylene Analyzer

- F-950 Three Gas Analyzer

- F-920 Check It! Gas Analyzer

- F-960 Ripen It! Gas Analyzer

- F-940 Store It! Gas Analyzer

Most Popular Articles

- Spectrophotometry in 2023

- The Importance of Food Quality Testing

- NIR Applications in Agriculture – Everything…

- The 5 Most Important Parameters in Produce Quality Control

- Melon Fruit: Quality, Production & Physiology

- Fruit Respiration Impact on Fruit Quality

- Guide to Fresh Fruit Quality Control

- Liquid Spectrophotometry & Food Industry Applications

- Ethylene (C2H4) – Ripening, Crops & Agriculture

- Active Packaging: What it is and why it’s important