November 3, 2025 at 5:15 pm | Updated November 3, 2025 at 5:15 pm | 9 min read

- Gray mold infection and rachis browning are the two main factors responsible for post-harvest quality loss of table grapes.

- Loss of appearance, weight, and firmness, shriveling, wilting, and bruising are some of the other prominent quality issues seen in postharvest grape clusters.

- Rapid moisture loss in berries, handling, and diseases are the three major postharvest causes for quality deterioration in grapes.

Table grapes are a popular food choice, and their consumption is on the rise. The fruit is delicate and prone to damage during handling, resulting in water loss and a decline in quality and quantity. To make the most of increased demand, supply chain stakeholders must ensure the grapes meet consumer expectations by avoiding and limiting the common quality problems discussed in this article.

Table Grapes

Grape (Vitis vinifera L.) is cultivated around the world for fresh consumption, raisins, juice, and wine. It is nutritious, being rich in anthocyanins, flavonoids, phenolics, and resveratrol. The proportion of grapes eaten fresh has traditionally been low, though the trend is changing as higher living standards drive demands for table grapes.

Grapes are non-climacteric and have low physiological activity rates. Being non-climacteric, grapes are harvested when ripe, resulting in short transport times and delicate fruits that are easy to handle. Significant postharvest losses occur during storage and transport due to several reasons.

Subscribe to the Felix instruments Weekly article series.

By submitting this form, you are consenting to receive marketing emails from: . You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact

The main quality problems seen in table grapes are:

- Berry size

- Uneven ripening

- Rachis drying and browning

- Mold spoilage and decay

- Postharvest rots

- Loss of visual appeal

- Berry shatter

- Bruising and wounding

- Shriveling and wilting of grape berries

- Weight loss

- Loss of firmness

Due to the various problems, an estimated 27% of the grape harvest is lost. Rachis browning and gray mold are the two main quality problems that affect table grapes.

-

Grape Size

Small, undersized grape berries are a result of too many clusters or berries in a cluster. The color and taste development of small grapes is not optimal, as photosynthetic compounds are distributed among too many fruits. Large berries can also be a problem and may be caused by excessive irrigation or fertilizer use. Despite their large size, these berries can also have less soluble sugar content and be less sweet.

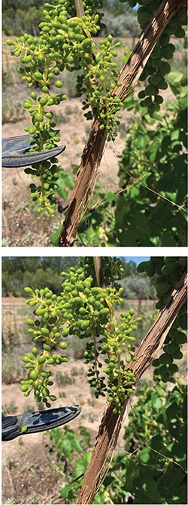

Figure 1. “Cluster at correct stage for berry thinning; when the berries are pea-sized or slightly smaller, remove the lower half of the cluster,” Giese. (Image credits: https://pubs.nmsu.edu/_h/H311/index.html)

-

Uneven Ripening

Usually, grape clusters ripen at the same time, but certain conditions and years produce uneven ripening. Uneven ripening is caused by genetics, microclimate variability, nutrient imbalance, vine vigor, water and environment stress, vine age, and closed cluster.

Uneven ripening and berry size optimization must be addressed during the preharvest stages and require ongoing action throughout the season. Pruning, canopy management, cluster thinning, and berry thinning (removing the lower parts of the cluster) can improve berry distribution within clusters, allowing better sunlight penetration; see Figure 1. Multiple harvesting, allowing unripe clusters to ripen on the vine, can produce even grape ripeness in a batch and enhance grape quality.

-

Rachis Drying and Browning

Cluster stem or rachis browning and drying is the second most significant quality problem, caused by moisture loss, partly during storage. Rapid moisture loss is the primary cause of rachis drying and browning, leading to quality and quantitative losses during postharvest stages. Rachis browning occurs when grapes are removed from cold storage and exposed to ambient conditions. Critical water-loss thresholds for various grape cultivars have been identified, allowing stakeholders to prevent this issue.

Another cause of rachis browning is sulfur dioxide fumigation used to control pathogens.

Rachis Browning influences consumer choice, which in turn drives food loss.

Rachis Browning can also lead to weight loss; for example, Thompson Seedless’s clusters lose 3.1% of their weight. Dry stems also become brittle, causing the berries to detach. The susceptibility to rachis browning depends on cultivars. For instance, ‘Superior’ grapes are more affected by browning than Thompson Seedless grapes at 20 °C.

A treatment with 1-MCP reduces rachis browning, while ethylene increases rachis browning; see Figure 2.

Figure 2: “Untreated (left) and 1-MCP-treated (right) rachis of ‘Thompson Seedless’ after cold storage,” Li et al. (2015). (Image credits: https://doi.org/10.1016/j.postharvbio.2015.04.001)

-

Mold

Gray mold infection, caused by the fungus Botrytis cinerea, is the most significant postharvest quality problem affecting grapes. The mold can grow at very low temperatures of 31°F (-0.5 °C) and spread between berries. The grapes turn brown, the skin becomes loose, and white hyphal threads that later turn grey can envelope the berries completely. Wounds on the peel increase the chances of mold infection.

Gray mold can develop pre- and postharvest. The preharvest remedies are canopy management, removing infected grapes from the previous season, and culling split, cracked, or otherwise damaged grapes to reduce infection.

Some postharvest techniques used to control gray mold include cooling and fumigating grapes immediately after harvest. Sulfur dioxide is still widely used in the postharvest stages to control the pathogen. During storage, SO2 fumigation could be repeated every 7-10 days. During transport, SO2 pads can be included, as fumigation is not possible. However, SO2 can cause allergies in some people who consume grapes, and it also has several side effects that negatively affect grape quality. SO2 produces bleaching of berries, discoloration of rachis, and sulfurous off-odors. Therefore, chemical alternatives such as chitosan, ethanol, salt solutions, physical hot-water treatment, or biological treatments with Cryptococcus laurentii are being tested.

-

Postharvest Rots

Besides gray mold, some diseases can develop due to warmer temperatures during transport and marketing, when fruits are removed from cold storage. Fungi and bacteria cause these diseases, including black rot (Aspergillus niger), blue rot (Penicillium spp.), and Rhizopus rot (Rhizopus spp.). These quality problems are usually controlled by sulfur dioxide fumigation.

-

Loss of Appearance

Grapes can be green, pink, or purple-black. However, the development of a brown color is a sign of quality problems and can have various causes. Stakeholders must identify the reasons for taking remedial actions; however, many causes stem from preharvest conditions that persist but cannot be addressed during postharvest stages.

- Browning could also be due to sunburn, which reduces anthocyanin levels and makes grape berries bitter.

- Lenticels are spots on berries that do not affect taste, but lead to grapes being rejected by consumers.

- Russet are yellow-brown spots that develop on the peel during development due to lignin and quercetin, due to environmental or physiological conditions during cultivation.

- Color can change due to diseases like mold and rot. The affected berries should be culled to stop the spread of pathogens.

-

Berry Shatter

Shattering is the phenomenon when berries fall from the stem. A shattering of more than 20% can result in a loss for producers. Shattering is more common in seedless varieties, such as Thompson Seedless or Flame Seedless, as they are not as firmly attached to the stem as seeded varieties.

Various reasons exist for shattering, such as:

- Environmental stress during growth.

- Harvesting grapes late when they are very mature.

- Most of the shattering occurs due to rough handling during packing if the fruits are packed immediately after harvest.

- It occurs due to moisture loss during storage and transport.

Preharvest girdling or gibberellin application reduced shattering. Harvesting at the correct maturity can also minimize shatter. The harvest index for grapes is readily available. For example, in California, the soluble solids content (SSC) ranges from 14% to 17.5%, or a taste (SSC to titrable acidity (TA) ratio) of 20 or more.

Postharvest, ensuring a slight delay in packing can minimize shattering. If the grape bunches are packed in individual bags, the loose berries are in the bag and can still be sold with the cluster. Moreover, bagging reduces packing density and the possibility of shattering.

-

Bruising and Open Wounds

Grape berries are delicate and prone to problems due to handling at all stages in the supply chain. Bruising and open wounds are common problems. In bruising, the fruit skin remains unbroken, and symptoms may appear over time as brown, soft spots. When the pressure applied is very high during handling, the skin breaks and becomes a site of microbial spoilage. The bruised berries can be culled to save the rest of the batch.

Cracks and splits are the result of improper watering during cultivation.

-

Shriveling and Wilting

Shriveling and wilting are caused by moisture loss during storage and transport. Diseases like black rot and verticillium wilt also cause shriveling. Preharvest causes include sunburn and berry shrivel, a grape-ripening disorder that reduces berry sweetness and water accumulation, both of which are influenced by temperature and precipitation during cultivation.

Moisture loss during storage and transport can be controlled by maintaining low temperatures and high relative humidity.

-

Weight Loss

The moisture loss is due to fruit respiration and transpiration. Respiration utilizes the stored biochemical compounds to produce carbon dioxide and heat. The latter, combined with existing environmental conditions, can cause fruits to lose moisture, resulting in weight loss and wrinkling. Together, the two physiological processes that continue in fruits after harvest can lead to rejection, waste, and yield loss. A 4.5% water loss causes weight loss, and berries become soft. Wrinkles begin to appear when grape berries lose 5% or more of their moisture content. Packaging can be used to reduce moisture loss.

-

Loss in Firmness

Overripe grapes at harvest will make the fruit soft to the touch or develop mushy spots. Harvesting at the correct time can help resolve this issue.

Another reason for loss of firmness is waterberry, a condition that occurs during ripening. It produces soft berries and develops small, dark, necrotic, and sunken spots that expand. The affected berries are watery and flabby after ripening. It occurs due to too much nitrogen fertilizers, shading, or cool weather. The affected parts are trimmed during harvest and packing in a labor-intensive process.

Limiting Table Grape Quality Problems

Many of the quality problems arise during cultivation, so a coordinated effort across the supply chain will be necessary to improve postharvest table grape quality. Calcite sprays applied during cultivation can prevent rachis browning, shattering, wilting, and shriveling, thereby enhancing postharvest grape quality. Postharvest moisture loss can be reduced by minimizing cooling delays. Ensure proper handling, as it makes grapes susceptible to diseases. The use of controlled atmospheres during storage and transport can prevent or limit many quality problems, such as decay, senescence, softness, stem and fruit browning, off-flavors, and weight loss, that occur during the postharvest stages by reducing fruit respiration and transpiration, as well as other physiological processes.

Stakeholders at all stages can use advanced tools, such as the F-751 Grape Quality Meter, to non-destructively estimate quality parameters —such as SSC, TA, and color —to monitor changes in the external and internal quality of table grapes and take proactive measures to limit losses. Moreover, the instrument can help determine the optimal harvest date to avoid several quality issues.

Find out more about the F-751 Grape Quality Meter produced by Felix Instruments Applied Food Science and how it can help maximize the quality and quantity of your grape supply.

1. What are the most common causes of postharvest quality loss in table grapes?

The two primary causes are gray mold infection (caused by Botrytis cinerea) and rachis browning, which results from moisture loss and improper storage conditions. Other factors include rapid dehydration, poor handling, uneven ripening, and mechanical damage like bruising or shattering during packing and transport.

2. How can grape growers and distributors minimize postharvest losses?

Minimizing losses starts with good preharvest practices such as canopy management, pruning, and controlled irrigation. Postharvest, the focus should be on maintaining cold chain integrity, ensuring proper humidity, gentle handling, and timely cooling. The use of controlled atmospheres and monitoring tools like the F-751 Grape Quality Meter can also help track and preserve fruit quality.

3. Are there safer alternatives to sulfur dioxide (SO₂) for controlling gray mold?

Yes. While SO₂ fumigation is common, it can cause discoloration, off-odors, and allergic reactions in consumers. Emerging alternatives include biological control agents (like Cryptococcus laurentii), chitosan coatings, ethanol vapor, salt solutions, and physical treatments such as hot-water dips—all of which are being tested as more sustainable and consumer-friendly options.

Sources

Blanckenberg, A., Opara, U. L., & Fawole, O. A. Postharvest Losses in Quantity and Quality of Table Grape (cv. Crimson Seedless) along the Supply Chain and Associated Economic, Environmental and Resource Impacts. Sustainability, 13(8), 4450. https://doi.org/10.3390/su13084450

Crisosto, C.H., & Smilanick, J.L. (n.d.). Table Grapes Postharvest Quality Maintenance Guidelines. Retrieved from https://ucanr.edu/sites/default/files/2011-10/123831.pdf

Crisosto, C.H., Smilanick, J.L., & Dokoozlian, N.K. (2001). Table grapes suffer water loss, stem browning during cooling delays. Calif. Agric., 55, 39–42.

Crisosto, C.H., Garner, D., & Crisosto, G. (2002). Carbon dioxide-enriched atmospheres during cold storage limit losses from Botrytis but accelerate rachis browning of ‘Red Globe’ table grapes. Postharvest Biol. Technol., 26, 181–189.

Giese, G. (n.d.). Improving Size and Quality of Seedless Grapes. Retrieved from https://pubs.nmsu.edu/_h/H311/index.html

Huang, Y., Liang, D., Xia, H., Lin, L.-J., Wang, J., & Lv, X.-L. (2020). Lignin and Quercetin Synthesis Underlies Berry Russeting in ‘Sunshine Muscat’ Grape. Biomolecules, 10(5), 690. https://doi.org/10.3390/biom10050690

Jiang, L., Jin, P., Wang, L., Xuan, Y., Wang, H., & Zheng, Y. (2015). Methyl jasmonate primes defense responses against Botrytis cinerea and reduces disease development in harvested table grapes. Sci. Hortic., 192, 218–223.

Kitinoja, L., & Al Hassan, H. Y. (2010). Identification of appropriate postharvest technologies for small-scale horticultural farmers and marketers in sub-Saharan Africa and South Asia-Part 1. Postharvest losses and quality assessments. In XXVIII International Horticultural Congress on Science and Horticulture for People (IHC2010): International Symposium on 934 (pp. 31-40).

Li, L., Kaplunov, T., Zutahy, Y., Daus, A., Porat, R., & Lichter, A. (2015). The effects of 1-methylcyclopropane and ethylene on postharvest rachis browning in table grapes. Postharvest Biol. Technol., 107, 16–22.

Nasrollahiazar, E., & Sabbatini, P. (2023, August 15). Understanding and Addressing Uneven Ripening of Grape Berries: A Comprehensive Guide. Retrieved from https://www.canr.msu.edu/resources/understanding-and-addressing-uneven-ripening-of-grape-berries.

Ngcobo, M.E.K., Delele, M.A., Pathare, P.B., Chan, L., Opara, U.L., & Meyer, C.J. (2012). Moisture loss characteristics of fresh table grapes packed in different film liners during cold storage. Biosyst. Eng., 113, 363–370.

Sabir, F.K., & Sabir, A. (2013). Quality response of table grapes (Vitis vinifera L.) during cold storage to postharvest cap stem excision and hot water treatments. Int. J. Food Sci. Technol., 48, 999–1006.

Sabir, F.K., & Sabir, A. (2017). Extending postharvest quality attributes of grapes (V. vinifera L. cv. ‘Thompson Seedless’) by preharvest calcium pulverizations. Acta Sci. Pol. Hortorum Cultus, 16, 29–38.

UCDavis Department of Plant Science. (n.d.). Grape: Shatter. Retrieved from https://postharvest.ucdavis.edu/disorders/grape-shatter

Zufferey, V., Spring, J.-L., Voinesco, F., Viret, O., & Gindro, K. (2015). Physiological and histological approaches to study berry shrivel in grapes. OENO One, 49(2), 113–125. https://doi.org/10.20870/oeno-one.2015.49.2.89

Related Products

- F-751 Grape Quality Meter

- Custom Model Building

- F-910 AccuStore

- F-751 Melon Quality Meter

- F-751 Kiwifruit Quality Meter

- F-750 Produce Quality Meter

- F-751 Avocado Quality Meter

- F-751 Mango Quality Meter

- F-900 Portable Ethylene Analyzer

- F-950 Three Gas Analyzer

- F-920 Check It! Gas Analyzer

- F-960 Ripen It! Gas Analyzer

- F-940 Store It! Gas Analyzer

Most Popular Articles

- Spectrophotometry in 2023

- The Importance of Food Quality Testing

- NIR Applications in Agriculture – Everything…

- The 5 Most Important Parameters in Produce Quality Control

- Melon Fruit: Quality, Production & Physiology

- Fruit Respiration Impact on Fruit Quality

- Guide to Fresh Fruit Quality Control

- Liquid Spectrophotometry & Food Industry Applications

- Ethylene (C2H4) – Ripening, Crops & Agriculture

- Active Packaging: What it is and why it’s important