December 9, 2025 at 6:02 pm | Updated December 9, 2025 at 6:02 pm | 9 min read

- The primary quality issues with apples are water loss, physiological disorders, storage disorders, microbial decay, and mechanical injuries.

- Some of the factors that influence post-harvest apple quality include harvest maturity, storage conditions, proper handling, and growing conditions throughout the supply chain.

- The susceptibility of apples to quality problems can vary by cultivar; therefore, growing, storage, and handling conditions must be tailored to each cultivar.

Apple (Malus domestica Borkh.), belonging to the Rosaceae family, is a temperate climacteric fruit. It is a popular fruit with numerous uses, and its ability to store for months makes it a valuable food commodity. However, apples can face several postharvest quality issues due to pre- and post-harvest factors, leading to rejection by retailers and consumers and resulting in economic losses and food waste. This article addresses some of the primary issues affecting apples.

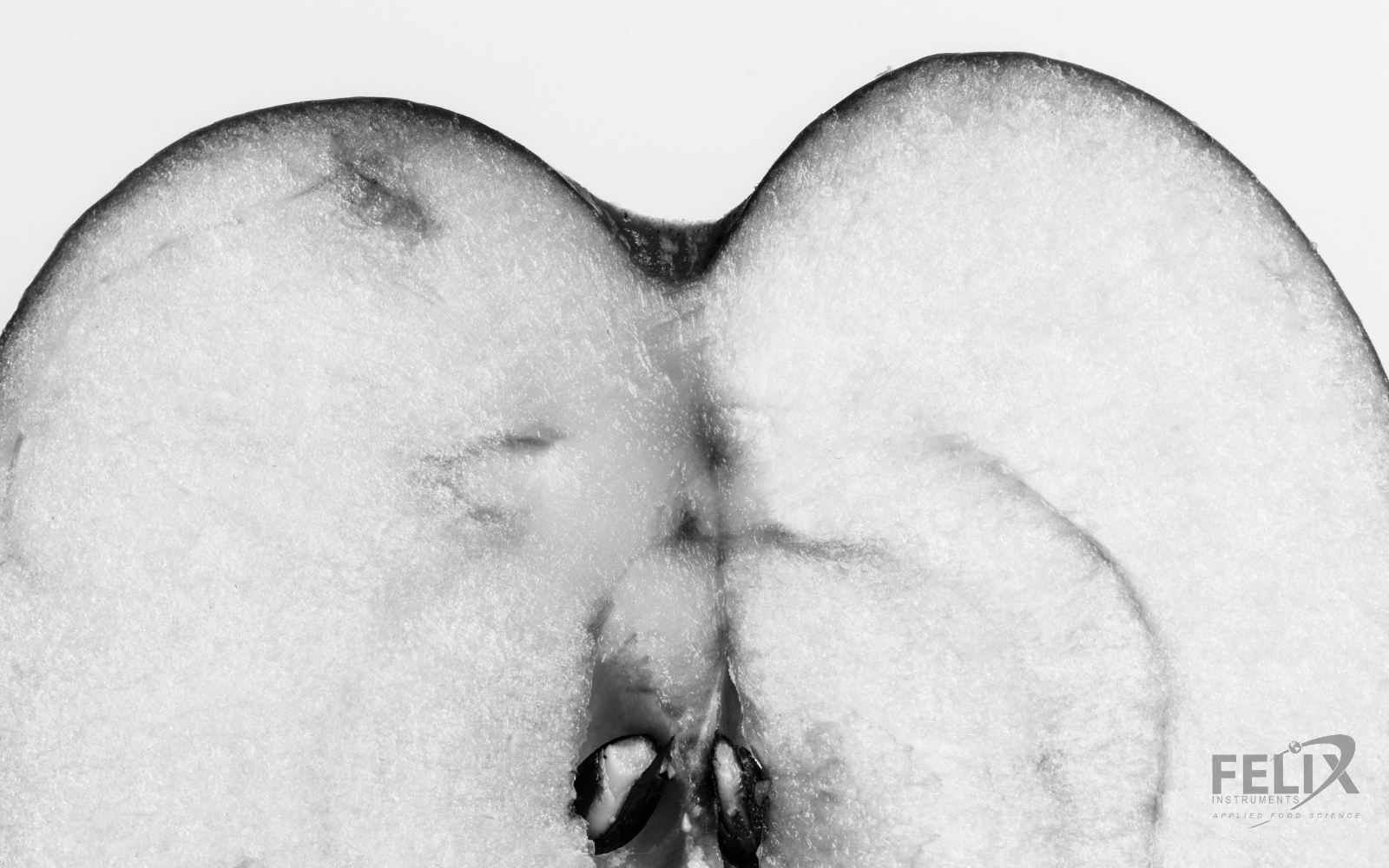

Consumer Preference for Apples

Figure 1: “The ‘perfect apple’ according to consumer preferences in Albania,” Marku & Mero (2024). (Image credits: DOI: https://doi.org/10.62792/ut.jasrd.v2.i3-4.p2669).

Subscribe to the Felix instruments Weekly article series.

By submitting this form, you are consenting to receive marketing emails from: . You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact

Several studies have investigated the quality traits that influence consumer choice of apples. The intrinsic fruit qualities sought after by people are size, shape, color, flavor, crispness, and sweetness. For example, as shown in Figure 1, Albanian consumers prioritize juiciness (34%) the most, followed by appearance (24%) in their choice of the “perfect apple.”

The studies note that people are not ready to compromise on taste for food safety. Globally, consumers tend to reject apples that do not appear appealing. Sadly, consumers are unlikely to accept “ugly” misshapen fruits, even if their nutritional value is high. Quality problems occur at various stages in the supply chain, and retailers reject apples that do not meet aesthetic standards upon arrival at the store.

Fresh apples have various sales channels. For example, in Australia, 83% is slated for fresh consumption and is sold to retailers, supermarkets, and other stores, while 17% is allocated to the food service industry. Additionally, other uses include juice, cider, canning, and jams. Sales of apples can be directed from the farm at the farmgate and farmers’ markets, or to supermarkets and retailers, or through export that involves wholesale supply chains. In direct sales, fruits rejected by consumers and retailers are sent for processing.

Quality Problems

In all cases, not being able to deliver good-quality fruit impacts apple sales, as the perceived quality of apples is related to their value. Quality problems often begin to develop on the farm and can persist throughout the supply chain, while others arise during handling, storage, and display.

The primary postharvest issues are water loss, physiological disorders, mechanical injuries, microbial decay, and storage-related injuries.

Water Loss

Figure 2: “The signs of water loss expressed as shriveling in ‘Cripps Pink’ apple during the postharvest period,” Hasan et al. (2024). (Image credits: https://link.springer.com/article/10.1007/s11947-023-03305-9)

Water loss is a significant constraint in the long-term storage of apples. Fruits that lose 5-10% of their water suffer quality loss. It negatively affects appearance, causing shriveling and reducing taste by diminishing crispness and juiciness, as shown in Figure 2. Moreover, the reduction in salable weight and storage time can decrease income for growers and other stakeholders. Apples stored at ambient temperature or without precooling have more water loss. For example, 28% more water loss occurs in apples that are not precooled.

The preharvest factors that increase water loss are cultivar, climate, fruit size, tree age, orchard practices, and harvest maturity. The postharvest factors that increase water loss are higher storage temperatures, lower relative humidity, storage method, and duration.

The mechanisms involved in water loss in apples are cuticle, lenticels, microcracking, mechanical injuries, storage disorders, and decay.

- Cuticles: The hydrophobic cuticle, which is composed of various waxes, is the main barrier against water loss.

- Lenticels: Since fruits have few stomata, most water loss or fruit transpiration occurs through lenticels, which can be 2-3 mm in size and are white to brown in color. Lenticel density is higher on the cheeks than in the pedicel area.

- Microcracks: These are natural openings in the cuticle that cause high water loss.

Remedies to prevent or reduce water loss are precooling, controlled atmosphere and cold storage, packaging, and the use of edible coatings. Precooling at 10 °C reduces water loss and shriveling. However, hydro-cooling at 4.5 °C can increase the incidence of rot and cracking.

Mechanical Injuries

Mechanical injuries can occur due to falls, shocks, vibrations, and compression resulting from improper harvest handling, packing, storage, and transport, leading to loss of quality and value in apples. For example, mechanical injuries can affect 25-50% of apples in China.

Mechanical injuries occur due to falls during picking, compression by the picker’s or handler’s hands, and contact with ladders and crates. Stacking apple cartons too high can lead to compression. Approximately 35% of mechanical injuries occur during picking and on-site handling, while 10% occur during storage.

Some of the main impacts include bruising, tissue damage, browning of flesh, reduction in firmness, increased susceptibility to microbial contamination, and increased ethylene and respiration rates. Mechanical injuries are complex and can lead to significant long-term damage. Fruit maturity at harvest is the most critical factor in determining the extent of mechanical damage. More mature fruits, due to softening, higher moisture content, and reduced cell integrity, are susceptible to bruising.

Bruising: It is the most common mechanical impact in apples that leads to tissue damage, loss of water, and appearance, accounting for 10-25% of postharvest losses in the apple supply chain. Bruise severity depends on the cause of injury, the variety, and harvesting conditions and methods.

Flesh browning: Apple flesh can darken and turn brown due to compression and oxidation of inner tissue; for example, a 70-N force in Gala apples causes darkening.

Tissue damage. Due to compression and impacts, internal tissue can break down, leading to cell necrosis in the damaged area and a “cell death zone”. The tissue damage spreads over time, both deeper into the apple core (60%) and laterally (40%).

Change in physiology: Mechanical injury increases ethylene production, a stress hormone, and fruit respiration rate. As a result, the apple’s soluble sugar contents (SSC), tartaric acidity (TA), and firmness are reduced, affecting appearance, crispness, and taste.

Microbial Decay

Postharvest losses of apples due to pathogens’ damage depend on various factors. According to Argenta et al. 2021, these losses can be:

- 0-70% due to harvest maturity, growing region, and year

- 2-40% because of storage duration and year. During storage, higher relative humidity can increase the risk of fungal decay.

- 25-25% from orchard practices and postharvest fungicide treatments

Several bacterial and fungal species cause postharvest losses; however, fungal decay is the primary concern, as more than 90 postharvest pathogens can affect apples. Postharvest fungal decay occurs from latent preharvest infection or fruit wound infection before or after harvest.

- Latent infections: These occur when microbes enter through natural lenticels. The causal pathogens Colletotrichum spp., Alternaria spp., Neofabraea spp., Fusarium spp., Phacidiopycnis washingtonensis, and Sphaeropsis pyriputrescens.

- Wound infections: These infections result from injuries caused by insects, hail, mechanical damage, and physiological disorders. Pathogens involved are Penicillium spp., Botrytis spp., Mucor spp., and Monilia spp.

Common fungal pathogens of apples include Penicillium expansum (blue mold), Botrytis cinerea (gray mold), and Mucor piriformis. P. expansum is responsible for 50% of postharvest decay and loss during storage. It causes water loss and lower firmness and SSC. In some cultivars, like ‘Anna,’ the production of antioxidants and phenols also decreases.

Remedies can include accurate maturity monitoring and harvest date prediction, which can enhance resistance to microbial decay. Most fungi flourish at higher temperatures, so cold storage can effectively control fungal decay. However, some species are active even at 2°C, making it challenging to prevent fungal decay.

Physiological Disorders

Apples can develop various physiological disorders that negatively affect their appearance, texture, taste, and flavor, leading to a potential 80% loss of stored fruits. Pre- and postharvest factors, including genotype and environment, influence the incidence of disorders.

Figure 3: Preharvest fruit cracking, John Strang, University of Kentucky. (Image credits: https://fruitscout.mgcafe.uky.edu/fruit-cracking-stem-end-splitting-and-internal-ring-cracking-apple)

Preharvest Disorders

According to the University of Washington, common preharvest physiological disorders that persist after harvest in apples include flesh browning, cracking, frost injury, sun scald, watercore, and russeting.

Skin cracking, internal cracking, and stem-end splitting: These problems occur on the tree due to rapid fruit expansion, due to excessive irrigation or rainfall. The susceptibility also depends on cultivars. ‘Stayman Winesap’ shows fruit cracking, while ‘Gala’ is prone to stem-end splitting and internal ring cracking, where a concentric crack is formed near the stem. Harvesting at the correct maturity, not too late, can prevent this problem.

Freeze injury: Freezing conditions in orchards cause many shape disorders (pumpkin apple symptom) and skin disorders (frost ring). The result is “ugly fruits” that are likely to be rejected.

Russeting: It is a wound-healing response that occurs in fields due to frost injury, rain, high humidity, temperature fluctuations, pesticide sprays, and physiological causes, such as cuticle development. Damaged cuticles lead to the formation of periderm and the deposition of cork cells, resulting in a brownish discoloration of the apple skin, known as russeting. This condition negatively affects the appearance and can lead to apple rejection. Physiological causes of skin russeting are the changes in ursolic acid and oleanolic acid in the cuticle. Microcracking can also cause russeting. Some cultivars, like Golden Delicious, are susceptible to russeting.

Sunscald: Intense sunlight and high temperatures, accompanied by water stress, produce sunscalds. Light-skinned varieties are more susceptible to this disorder. Proper pruning and training, combined with irrigation, can help mitigate this quality issue.

Greasiness: The apple skin’s natural greasiness is affected due to alterations in esters and alcohols in the cuticle.

Scalds: Superficial scalds occur due to wax composition changes.

Storage Disorders

Some disorders develop postharvest due to temperature (high and low), low oxygen (O2), high carbon dioxide (CO2), relative humidity, and storage duration. The disorders can vary among cultivars. Extended storage periods lead to increased physiological disorders.

Senescent cracking and mealy texture: Small cracks in the fruit skin enlarge as storage time or ripeness increase postharvest. The exposed flesh develops a mealy texture and a dry consistency, and loses juiciness and flavor. It also increases the chances of microbial decay. Timely harvest or reducing storage time can prevent this problem.

Chilling injury: Apples stored for more than three months at temperatures below 0°C, when removed to ambient conditions, can develop chilling injury. Chilling injury can be cultivar-specific, for example, Honeycrisp, and include soft scald and soggy breakdown.

- A soft, sunken, dark brown patch with rigid borders on the apple skin characterizes soft scald symptoms.

- Soggy breakdown occurs in the deeper layers of the apple, where a spongy, soft, brown tissue develops.

Brown core disorder: Excessive water loss during storage can lead to the development of a brown core. It is the discoloration of apple flesh, characterized by brown and pink spots in the core. ‘Honeycrisp™’ cold-stored for 4 months at 3.5 °C shows these symptoms.

Watercore: Watercore occurs during cold storage due to water loss and depends on storage duration. For example, after 180 days in cold storage, ‘Fuji’ can lose 9.2% of its water and develop these symptoms. Watercores can also develop preharvest due to over-ripening and cool temperatures. Harvesting at the correct time, before the fruit is over-ripe, can reduce the problem.

Flesh browning: High CO2 in controlled atmospheres slows ripening rates. However, it can lead to flesh browning, cracking, and rough skin. Some varieties, like ‘Monalisa’, are very susceptible, especially in late-harvested apples.

Alcoholic flavor: Very low O2 in controlled atmospheres can result in anaerobic fermentation and the development of alcoholic flavor in apples.

Remedies for storage disorders require optimizing gas and temperature levels in controlled-atmosphere storage facilities. Usually, apples are stored at 0°C. However, varieties susceptible to low temperatures must be stored above zero. Intermittent warming can relieve chilling injury and superficial scald.

Various apple cultivars have different shelf-lives due to varying harvest maturity and storage techniques, so information transfer along the supply chain can be crucial.

Limiting Apple Quality Problems

Correct harvest maturity and proper storage conditions are crucial for preventing loss of apple quality. To fix the correct harvest time, well-established harvest maturity indices for various varieties can be used. Instruments such as the F-750 Produce Quality Meter, which measures SSC, TA, and external and internal color, can be used to optimize harvest timing. The CO2, O2, and ethylene gas levels, as well as temperature and relative humidity, can be monitored to control ripening and physiological disorders using F-901 AccuStore and F-940 Store It! Gas Analyzer.

Felix Instruments Applied Food Science manufactures these precision tools. Contact us to learn how we can help address apple quality issues.

Source

Argenta, L. C., de Freitas, S. T., Mattheis, J. P., Vieira, M. J., & Ogoshi, C. (2021). Characterization and Quantification of Postharvest Losses of Apple Fruit Stored under Commercial Conditions. HortScience, 56(5), 608–616. https://doi.org/10.21273/HORTSCI15771-21

Chen, Z., Jing, L., Liu, R., Yang, H., Sun, L., Cao, X., Wang, Y., Fu, S., Zhang, H., & Wang, J. (2026). From firm to soft: Maturity-driven mechanical damage behavior of apples. Postharvest Biology and Technology, 232, 114003. https://doi.org/10.1016/j.postharvbio.2025.114003

Hasan, M.U., Singh, Z., Shah, H.M.S. et al. Water Loss: A Postharvest Quality Marker in Apple Storage. Food Bioprocess Technol 17, 2155–2180 (2024). https://doi.org/10.1007/s11947-023-03305-9

Hetzroni, A., Bechar, A., Nir, I., Yosef, S., & Antler, A. (1998). Analysis Of Mechanical Injuries Caused To Apples Along The Fruit Handling Process. In 2001 ASAE Annual Meeting (p. 1). American Society of Agricultural and Biological Engineers.

Huey, N. S., Griffith, G., & Bittner, E. (2018). Issues in Measuring Quality in the Australian Apple Supply Chain. Australasian Agribusiness Perspectives 21, ISSN: 1442-6951. Retrieved from https://www.researchgate.net/publication/322931154_Issues_in_Measuring_Quality_in_the_Australian_Apple_Supply_Chain

Marku, D., & Mero, G. (2024). Quality Attributes And Food Waste In Apple Value Chain: A Consumer Perspective. Journal of Agriculture and Sustainable Rural Development 2, 65-71. DOI: https://doi.org/10.62792/ut.jasrd.v2.i3-4.p2669

Miroquesada, A., & Farcuh, M. (2024, October 21). Causes and Prevention of Chilling Injury in Honeycrisp Apples. Retrieved from https://extension.umd.edu/resource/causes-and-prevention-chilling-injury-honeycrisp-apples/

Rohr, S., Mounter, S., Fleming, E., & Griffith, G. (2020). The Australian apple industry–trends and challenges. Australasian Agribusiness Review, 28(2), 28-46.

Shewa AG, Gobena DA, Ali MK (2022) Review on postharvest quality and handling of apple. J Agric Sc Food Technol 8(1): 028-032. DOI: 10.17352/2455-815X.000141

Thewes, F. R., Argenta, L. C., Anese, R. D. O., Stanger, M. C., & De Freitas, S. T. (2023). The response of ‘Monalisa’ apples to high CO2 storage conditions, harvest maturity and 1-MCP treatment. Scientia Horticulturae, 317, 112038. https://doi.org/10.1016/j.scienta.2023.112038

University of Kentucky, Department of Plant Pathology. (n.d.). Physiological Disorders of Apple. Retrieved from https://fruitscout.mgcafe.uky.edu/physiological-disorders-apple

Xu, T., Zhang, X., Zhu, Y., Xu, X., & Rao, X. (2024). Evolution Pattern in Bruised Tissue of ‘Red Delicious’ Apple. Foods, 13(4), 602. https://doi.org/10.3390/foods13040602

Related Products

- F-751 Grape Quality Meter

- Custom Model Building

- F-910 AccuStore

- F-751 Melon Quality Meter

- F-751 Kiwifruit Quality Meter

- F-750 Produce Quality Meter

- F-751 Avocado Quality Meter

- F-751 Mango Quality Meter

- F-900 Portable Ethylene Analyzer

- F-950 Three Gas Analyzer

- F-920 Check It! Gas Analyzer

- F-960 Ripen It! Gas Analyzer

- F-940 Store It! Gas Analyzer

Most Popular Articles

- Spectrophotometry in 2023

- The Importance of Food Quality Testing

- NIR Applications in Agriculture – Everything…

- The 5 Most Important Parameters in Produce Quality Control

- Melon Fruit: Quality, Production & Physiology

- Fruit Respiration Impact on Fruit Quality

- Guide to Fresh Fruit Quality Control

- Liquid Spectrophotometry & Food Industry Applications

- Ethylene (C2H4) – Ripening, Crops & Agriculture

- Active Packaging: What it is and why it’s important