August 26, 2021 at 11:01 pm | Updated April 11, 2022 at 6:44 am | 6 min read

Storing fruits and vegetables at low temperatures to extend storage time is standard practice in food supply chains. Low temperatures serve to delay senescence in non-climacteric fruits. However, refrigeration is energy intensive and there is a need to find an alternate method to store fresh produce to reduce the carbon footprint of food production. Reducing ethylene gas, the cause of senescence, is one possibility.

The Difficulty with Cold Storage

Increasing amounts of fresh produce are being shipped around the world using cold storage. The recommended storage temperatures for non-climacteric fresh produce is 0°C to delay senescence. However, the total energy used and the accompanying carbon emissions are high.

Currently, carbon emissions from food production have become a matter of global concern. Consultative Group on International Agricultural Research (CGIAR) lists food storage and packaging as one of the main reasons why farming produces one-third of the total global carbon emissions. Emissions produced in the post-harvest supply chain have increased by 50% since 1990, according to FAO (Food and Agriculture Organization of the United Nations).

Subscribe to the Felix instruments Weekly article series.

By submitting this form, you are consenting to receive marketing emails from: . You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact

As consumers seek to reduce their own carbon footprint, reducing energy use during storage is becoming necessary to retain a share of vast international markets.

Alternate Strategy

An alternate method exists to extend the postharvest life of fresh produce: reducing the ethylene gas concentration in the atmosphere in which produce is stored or transported.

Ethylene gas is a phytohormone produced by climacteric fruits that triggers ripening. It is an important hormone that is essential at many stages of plant life. However, this is also the gas that leads to over-ripening and senescence. While non-climacteric fruits do not need ethylene gas for ripening, the gas is produced during senescence.

Reducing ethylene gas concentrations to 0.001 μL L−1, instead of the standard level of 0.1 μL L−1 maintained in the postharvest environment, could extend fresh produce shelf life. When the ethylene levels are low, a higher storage temperature could theoretically be used without impacting fruit quality.

However, the interaction of various levels of ethylene gas and temperatures, and their ability to delay senescence and ripening, is not known. Moreover, most studies have been conducted on ripening effects on climacteric fruits.

Interaction of Temperature and Ethylene Gas

Li, Wills, and Golding, scientists from the departments of environmental science, advanced technologies for food manufacture, and primary industries, respectively, decided to examine the relationship between storage temperature and ethylene gas levels in four non-climacteric fresh produce:

- Pak choi (Brassica rapa subsp. chinensis),

- Mint (Mentha haplocalyx Briq. L.),

- Broccoli (Brassica oleracea var. italica), and

- Green bean (Phaseolus vulgaris L.)

The scientists took two batches of freshly harvested produce, with a gap of 1-2 months, for their experiment. Vegetables of uniform size and without any defects were chosen. Pak choi, broccoli, and green beans were subjected to sixteen treatments. They tested combinations of four levels of temperature—0, 5, 10, and 20°C—with four levels of ethylene gas concentrations—1, 0.1, 0.01, and < 0.001 μL L−1. For mint, only three different temperatures were considered—5, 10, and 20°C—to give twelve treatments.

Each replication/unit of produce was placed in plastic containers with inlet and outlet ports. These containers were kept in temperature-controlled chambers. The scientists had to measure ethylene gas levels daily, at the inlet port, through which it was introduced into the containers. For this, they took a sample of 1 mL of gas to control the level of ethylene supplied to the treatments. The scientists used flame ionization gas chromatography to measure ethylene gas concentrations.

The scientists used appearance, by which consumers would judge vegetables, to check fresh produce quality. This duplicated market situations and made it easy for them to make suggestions based on research results. However, the attribute measured was different in each case:

- Pak choi and broccoli were evaluated by color change on a 5-point scoring scale. Effective storage life was estimated as the point when they reached a score of 3, when over 30% of leaves turned yellow. Pak choi leaves were also checked for ascorbic acid levels.

- Mint leaves were judged by the number of leaves that were abscised every 12 hours. Loss of 40% leaves was considered the end of viable storage time.

- Beans were evaluated by chilling damage, on a 5 point scale, for produce stored at 0oC. Other temperature treatments were judged by loss in firmness on a 5-point scale. The time taken to reach score 3 was the storage time. After four days of storage, respiration of beans was measured by thermal conductivity gas chromatography.

Lower Ethylene Levels Delay Senescence

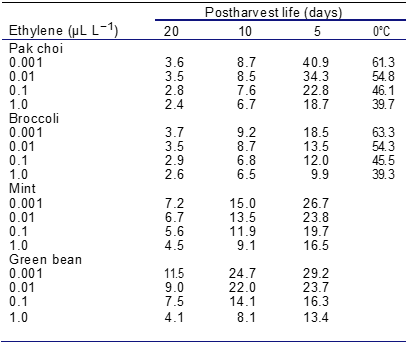

Table 1: “Postharvest life of pak choi, broccoli (as determined by leaf yellowing), mint (as determined by leaf abscission), and green bean (as determined by softening) after storage at different temperatures in the air with a range of ethylene concentrations,” Li et al. 2017. (Credits: DOI: 10.1080/14620316.2016.1263545)

Table 1 shows the interactions of temperature and ethylene gas levels on storage time. In each case, the results from this experiment exceeded the storage time achieved over industry standards.

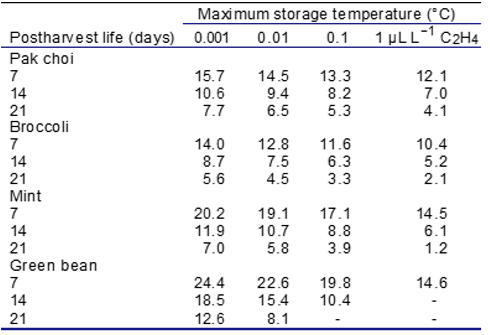

By analyzing the results of the experiment with regression equations, the scientist calculated the maximum temperatures needed to achieve storage time of 7, 14, and 21 days at the ethylene concentrations used. The results are shown in Table 2.

Pak Choi

In this experiment, when pak choi was stored at 0°C, which is the industry standard, the vegetable remained good for 40-60 days. Usually, pak choi is marketed well before 40 days after harvest. As shown in Table 2, if ethylene is reduced from the usual 1.0 to 0.001 μL L−1, temperatures can be maintained at 7°C if the vegetables are stored for 21 days or at 10°C if the vegetables are stored for only 14 days.

Broccoli

For broccoli, the recommended 0°C is not necessary if it is stored for only 21 days; 5°C is enough if ethylene gas concentrations are lowered to 0.001 μL L−1. A temperature of 8°C is enough for storing broccoli for 14 days.

Mint

A preliminary study had shown the scientists that storing mint at 0°C produced no leaf abscission even after 40 days of storage, so they eliminated this temperature even at the experimenting stage.

Storing mint at 6°C, regardless of the ethylene gas, achieves a storing time of 14 days.

Table 2. “Calculation from the regression equations of the maximum storage temperature of pak choi, broccoli, mint, and green bean that allows specific postharvest life periods at the ethylene concentrations examined,” Li et al. 2017. (Credits: DOI: 10.1080/14620316.2016.1263545 )

Beans

Green beans stored at 0°C suffered chilling damage and could not be used after two weeks of storage. With this vegetable, decreasing levels of ethylene gas increased storage time. If ethylene gas levels are decreased to 0.001 μL L−1, green beans can be stored at 18°C for 14 days. The storage temperature can be hiked four times higher for beans than for any of the other vegetables tested.

Ethylene Sensitivity

Depending on the results, the scientists concluded that the vegetables showed varying sensitivity to ethylene. Beans were most sensitive, followed by mint; broccoli and pak choi were the least sensitive to ethylene gas. Non-climacteric vegetables produce a small amount of ethylene themselves; if they are stored with climacteric fruits, or exposed to machinery, they could be experiencing at least 0.1 μL L−1 of the gas. So, taking steps to reduce the gas levels can extend storage time.

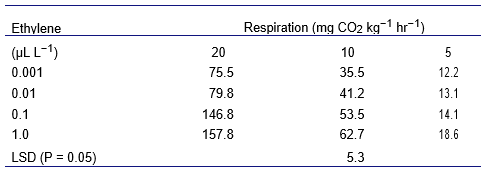

Moreover, reducing ethylene also reduced respiration in green beans, as shown in Table 3. This, in turn, reduces the heat produced during respiration and further reduces cooling needs. Even ascorbic acid levels remain optimum under lower temperatures or ethylene levels in pak choi.

Table 3. “Respiration, as evolved carbon dioxide, of green beans after 4 days stored at various temperatures and ethylene concentrations,” Li et al. 2017. (Credits: DOI: 10.1080/14620316.2016.1263545 )

Gas Analyzers

This experiment shows it is not necessary for any of the vegetables to be stored at 0oC, which is the common practice, even at higher concentrations of ethylene. This is a significant result by itself, as vegetables are rarely stored for the maximum time of 60 days, for which 0°C is recommended. However, lowering ethylene levels can have additional benefits in reducing energy use. Decreasing ethylene gas levels can delay senescence in the temperature range of 0 to 20°C. This level of ethylene reduction does require investment, but it is far less than the cost of energy and its use is not polluting.

Commercially available gas analyzers can help stakeholders monitor and measure ethylene levels during storage and transport. Felix Instruments — Applied Food Science produces a range of gas analyzers suitable to measure ethylene at different points of the supply chain. They give rapid and accurate readings and are user friendly. Suppliers and producers could consider using them to reduce their energy costs and carbon footprint.

—

Vijayalaxmi Kinhal

Science Writer, CID Bio-Science

Ph.D. Ecology and Environmental Science, B.Sc Agriculture

Source

FAO. (2021, June 8). Off-farm activities are a growing share of food-system greenhouse gas emissions. Retrieved from http://www.fao.org/news/story/en/item/1402118/icode/

Gilbert, N. One-third of our greenhouse gas emissions come from agriculture. Nature (2012). https://doi.org/10.1038/nature.2012.11708

Li, Y., Wills, R.B.H., & Golding, J.B. (2017) Interaction of ethylene concentration and storage temperature on postharvest life of the green vegetables pak choi, broccoli, mint, and green bean. The Journal of Horticultural Science and Biotechnology, 92:3, 288-293. DOI: 10.1080/14620316.2016.1263545

Related Products

- F-751 Grape Quality Meter

- Custom Model Building

- F-910 AccuStore

- F-751 Melon Quality Meter

- F-751 Kiwifruit Quality Meter

- F-750 Produce Quality Meter

- F-751 Avocado Quality Meter

- F-751 Mango Quality Meter

- F-900 Portable Ethylene Analyzer

- F-950 Three Gas Analyzer

- F-920 Check It! Gas Analyzer

- F-960 Ripen It! Gas Analyzer

- F-940 Store It! Gas Analyzer

Most Popular Articles

- Spectrophotometry in 2023

- The Importance of Food Quality Testing

- NIR Applications in Agriculture – Everything…

- The 5 Most Important Parameters in Produce Quality Control

- Melon Fruit: Quality, Production & Physiology

- Fruit Respiration Impact on Fruit Quality

- Guide to Fresh Fruit Quality Control

- Liquid Spectrophotometry & Food Industry Applications

- Ethylene (C2H4) – Ripening, Crops & Agriculture

- Active Packaging: What it is and why it’s important