October 21, 2020 at 9:14 pm | Updated October 21, 2020 at 9:14 pm | 6 min read

Quality parameters in plums (Prunus domestica) can be estimated non-destructively by near-infrared spectroscopy to improve harvest and post-harvest management. It has the advantage of being able to analyze internal characteristics of the fruit, such as soluble sugars content, acidity, firmness, taste, and internal color. Consistent monitoring can ensure consumer satisfaction and improve the prices producers get for their fruits.

Near-Infrared Spectroscopy

Spectroscopy is the technique of studying chemicals based on their interaction with light. The interaction can be absorption, reflectance, or transmission of light. The data is generated as a spectrum.

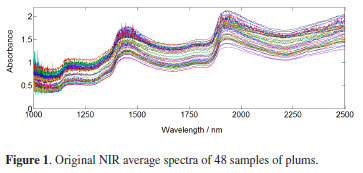

Near-infrared is the range between 750-2500 nanometers (nm) and is next to visible red light. This spectrum is suitable for finding the composition of a compound, as it reacts with the C-H, O-H, and N-H bonds. Thus, NIR spectroscopy is useful in qualitative and quantitative analysis of bio compounds; see Figure 1.

Subscribe to the Felix instruments Weekly article series.

By submitting this form, you are consenting to receive marketing emails from: . You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact

Being non-destructive, NIR spectroscopy can be repeated as many times as needed on a sample without reducing yield. Modern technology has miniaturized this complex process to fit into hand-held instruments.

Figure 1: Reflectance data for plums (Image credits: Costa and Lima, 2013. J. Braz. Chem. Soc. vol.24 no.8 São Paulo. https://doi.org/10.5935/0103-5053.20130172)

The F-750 Produce Quality Meter, manufactured by Felix Instruments – Applied Food Science, is NIR-based and is recommended by scientists for many fruits. It measures SSC by BRIX, titrable acidity, and color. Accurate, individual readings are given rapidly, within in 4-6 seconds. A built-in GPS makes mapping fruit trees easy.

A general instrument, F-750 can be modeled for specific fruits easily, including plums. Being portable it can be used by anyone anywhere in the supply chain, from farms to retail shops, as it is user-friendly and requires no special training to operate.

Advantages of NIR Spectroscopy over Traditional Methods

A single NIR spectroscopy based tool can replace several different methods and equipment to measure sugars, acidity, firmness, color, and other compounds in plums.

- SSC estimation: Traditional methods in use to detect sugar levels in plums are refractometers, gas and liquid chromatography, and chemical and enzymatic processes. NIR can be used instead of these methods, which requires destructive sampling and a laboratory. For example, a sample from juice taken from ten fruits is needed to measure BRIX by refractometers.

- Acidity: Titrable acid content measurements by NIR can be useful instead of the usual colored indicator or pH meter methods. Both these methods need to be done in a simple laboratory and involve destructive sampling of juice from ten fruits. They also require chemicals, some of which are explosive.

- Firmness: Penetrometers with detachable plungers of 8 mm diameter are used to test the firmness in plums.

NIR spectroscopy can be used to measure various quality and maturity parameters in plums.

Internal Parameters in Plums

Plums are consumed as fresh fruits and processed to produce prunes, Damson cheese, jams, and plum brandy. The internal parameters that are of interest in controlling the quality of plum and its products are sugars, acidity, aromatic compounds like phenols, and firmness.

Sugars

The fruit contains sugars such as fructose, glucose, sucrose, and sorbitol. As the fruit matures, the amount of fructose and glucose decreases and the level of sucrose increases in plums. The sugars serve the following purposes:

- The fermentation of fructose, glucose, and sucrose gives ethanol used for the distillates.

- Sorbitol is not useful for making alcohol, but is useful in processes where heat is used in drying or making Damson cheese. It protects the fruit from browning and changes in tastes, as it doesn’t get caramelized.

Taste

Plums have malic, tartaric, and citric acids, which are just as important as sugars for taste development. During the ripening process, the amount of acids, especially malic acid, decreases and there is a production of volatile compounds that enhance the taste of the fruits.

Firmness

Fruit flesh firmness decreases during maturation and ripening. Early-harvest plums are softer at maturity than late-harvest varieties.

Color

Internal flesh color changes, due to ripening and other physiological reasons, have been established as an important parameter in plums.

Maturity Index to Fix Harvest Time

Plum is a climacteric fruit, so it can be harvested when it is fully mature and then allowed to ripen and soften in storage or during transport. Traditionally, change in the color of skin and flesh, along with firmness of the flesh were used as indicators of maturity. Except for firmness, the other parameters are subjective.

A reliable maturity index needs to be objective, easy to measure, and also non-destructive. It has to be consistent over the years, regions, and varieties. Its use should ensure quality eating levels and extended storage time. NIR ticks all the boxes by integrating measurements of internal parameters and the older maturity indices.

- SSC/Acid Ratio: Soluble solids content (SSC) and concentration of acids are used to estimate maturity. The ratio of sugar to titrable acidity was found to be a more reliable maturity index than either of the parameters alone.

- SSC: A large number of varieties can make SSC use, alone, challenging as a maturity index. Also, the season, the farm, and even the position of fruits on the trees can affect SSC. It is more a quality index than harvest index for plums.

- Titrable acidity: Acidity decreases during maturity. This parameter, alone, is also not a great maturity index as it can be affected by cultivar and seasons.

- Firmness: By itself, firmness is not a reliable maturity index, as it varies depending on variety, size of fruits, climate, and also cultural practices.

- Color: In plums, the color of the external skin can be used in combination with firmness as a maturity index to set the harvest date.

Post-Harvest Management

NIR spectroscopy can be used to measure BRIX, titrable acidity, taste, and internal color in quality control during storage, sorting, distribution, and price-fixing.

In plums that are going to be marketed as fresh fruits, SSC, titrable acidity, pH, malic acid, tartaric acid, and anthocyanin are important quality parameters.

Multiculivar models have been developed for predicting SSC, total acidity, pH, and firmness of plums by NIR, and they are robust across season and location. These models can be used to monitor ripening.

Ripening

Ripening time and post-harvest management in plums are influenced by the temperature at which they are stored. If they are cooled immediately after picking to temperatures between 0-4oC, they can be stored for 3-6 weeks. However, storage at lower temperatures can spoil the fruits. By monitoring ripening, management practices can be altered as necessary.

By sorting plums based on their stage of ripening, they can be stored in different batches to prevent ethylene production from ripe fruits spoiling the less ripe ware. Plums are very sensitive to ethylene, so proper sorting and storage are vital.

Detection of Plum Browning

Plum flesh can turn brown as a result of storage temperatures that are too low or because the fruit is too old. Browning can also occur due to brown rot, which changes the texture, making the flesh mealy, the color changes to brown, and the flavor is lost. These changes cannot be detected externally and the fruit still looks fine, until it is eaten; see figure 2.

NIR can successfully detect browning, so the spoiled goods can be culled to maintain the quality of the batch and fetch higher prices.

Figure 2: Chilling injury in plums causes browning in the fruits, seen on the right-hand side of the picture. (Photo Credit: Don Edwards, UC Davis, http://postharvest.ucdavis.edu/Commodity_Resources/Fact_Sheets/Datastores/Fruit_English/?uid=52&ds=798 )

Variety Discrimination by Tasting

A favorable sugar/acid ratio is maintained to get the right flavor. In addition, NIR has been used to measure taste in plums produced not only by SSC and total acidity, but due to other volatile compounds like phenols. Based on the taste measurement, NIR can accurately sort fruits into respective varieties, even if they have the same SSC and titrable acidity.

Tasting fruits non-destructively can be used to grade plums in warehouses and retailing to check for authenticity and price fixing.

Quality Control

Though NIR can estimate maturity indices and fix harvest time, it is more popularly used to monitor internal quality in plums. Increased sample analysis in production batches ensures higher quality through frequent control during all stages of the supply chain. As a result, plum production is optimized and becomes more profitable for all stakeholders by ensuring harvest at the right stages, precise storage conditions, and reducing waste.

—

Vijayalaxmi Kinhal

Science Writer, CID Bio-Science

Ph.D. Ecology and Environmental Science, B.Sc Agriculture

Feature image courtesy of Marcu Loachim

Sources

A plum that’s brownish inside? (2020, March 05). Retrieved May 13, 2020, from https://www.eatortoss.com/single-post/2020/03/04/A-plum-thats-brownish-inside

Abu-Khalaf, N., Bennedsen, B. (2002). Plum-tasting using near infra-red (NIR) technology. Int. Agrophys., 16(2), 83-89.

Bohačenko, I., Pinkrová, J., Komárková, J., & Paprštein, F. (2010). Selected processing characteristics of new plum cultivars grown in the Czech Republic. Horticultural Science, 37(No. 2), 39-45. doi:10.17221/26/2009-hortsci

Costa, R. C., & Lima, K. M. G. de. (2013). Prediction of parameters (soluble solid and pH) in intact plum using NIR spectroscopy and wavelength selection. Journal of the Brazilian Chemical Society, 24(8), 1351-1356. https://doi.org/10.5935/0103-5053.20130172

Crisosto.C. H. (1994). Stone fruit maturity indices: a descriptive review. Postharvest News and Information, 5 (6), 65N-68N.

Li, M., Lv, W., Zhao, R., Guo, H., Liu, J., & Han, D. (2017). Non-destructive assessment of quality parameters in ‘Friar’ plums during low temperature storage using visible/near infrared spectroscopy. Food Control, 73, 1334-1341. doi:10.1016/j.foodcont.2016.10.054

Louw, E. D., & Theron, K. I. (2010). Robust prediction models for quality parameters in Japanese plums (Prunus salicina L.) using NIR spectroscopy. Postharvest Biology and Technology, 58(3), 176-184. doi:10.1016/j.postharvbio.2010.07.001

Organization for Economic Co-operation and Development. (2005). Guidance on Objective Tests to Determine Quality of Fruits and Vegetables and Dry and Dried Produce. Retrieved from https://www.ble.de/SharedDocs/Downloads/EN/Nutrition-Food/Quality-Control/BestimmungFruechteEN.pdf

Plums. (n.d.). Retrieved May 12, 2020, from https://cargohandbook.com/Plums

Teerachaichayut, S., Phonmakham, S., and Suktanarak, S. (2017). Grouping marian plums harvested at different times by transmittance near-infrared spectroscopy. Acta Hortic. 1179, 25-30, DOI: 10.17660/ActaHortic.2017.1179.5

Zhao, Z.L., Wang, Y.W., Gong, D.J., Niu, X.Y, Cheng, W., & Gu, Y.H. (2016). Discrimination of Plum Browning with Near Infrared Spectroscopy. Guang Pu Xue Yu Guang Pu Fen Xi, 36(7): 2089-93. PMID: 30035890

Related Products

- Felix Expansion Card

- F-751 Grape Quality Meter

- Custom Model Building

- F-910 AccuStore

- F-751 Melon Quality Meter

- F-751 Kiwifruit Quality Meter

- F-750 Produce Quality Meter

- F-751 Avocado Quality Meter

- F-751 Mango Quality Meter

- F-900 Portable Ethylene Analyzer

- F-950 Three Gas Analyzer

- F-920 Check It! Gas Analyzer

- F-960 Ripen It! Gas Analyzer

- F-940 Store It! Gas Analyzer

Most Popular Articles

- Spectrophotometry in 2023

- The Importance of Food Quality Testing

- NIR Applications in Agriculture – Everything…

- The 5 Most Important Parameters in Produce Quality Control

- Melon Fruit: Quality, Production & Physiology

- Fruit Respiration Impact on Fruit Quality

- Guide to Fresh Fruit Quality Control

- Liquid Spectrophotometry & Food Industry Applications

- Ethylene (C2H4) – Ripening, Crops & Agriculture

- Active Packaging: What it is and why it’s important