October 21, 2020 at 9:13 pm | Updated October 21, 2020 at 9:13 pm | 6 min read

Visual to near-infrared spectroscopy (Vis-NIR) is widely used in the supply chain to optimize the production of fruits. The application of this versatile technique is being tested and tried for an increasing number of fresh produce. Recent research shows which internal parameters in cherries can be estimated non-destructively by NIR spectroscopy. Based on their findings, scientists recommend the use of handheld devices with NIR spectroscopy for the frequent analyses necessary to monitor quality and setting harvest dates in a wide variety of cherries.

NIR Spectroscopy

NIR spectroscopy is the interaction of the NIR spectrum (760–2500 nanometers [nm]) of light with the atomic bonds within chemicals. In the case of NIR, bonds involving hydrogen, such as O–H, C–H, and N-H, are vital. Since these bonds have different energies, the difference in their interaction with NIR helps in the identification and quantification of the chemicals.

The three interactions that are used in NIR spectroscopy are reflection, absorption, and transmission of NIR.

Subscribe to the Felix instruments Weekly article series.

By submitting this form, you are consenting to receive marketing emails from: . You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact

Small, handheld devices that have miniaturized the complex technique of NIR spectroscopy are important for the cherry industry. They have the following advantages:

- Onsite use in the entire supply chain – farms, cold storage, transport, retailing, and processing

- Precise, objective, and rapid readings that are easy to understand

- Operation is simple, so all personnel can use the tools without training

There are an estimated 1500 varieties of cherries, belonging to two species:

- Prunus avium, or sweet cherries, which are usually consumed as fresh fruits

- Prunus cerasus, or sour cherries, which are processed into juice and brandy and are used for cooking

Recent research findings have confirmed that NIR spectroscopy can be used in cherry varieties to detect and quantify

- Firmness

- Soluble Sugar content (SSC)

- Dry matter (DM)

- Acidity

- Color intensity or chroma

F-750 Produce Quality Meter

Based on NIR spectroscopy, the F-750 Produce Quality Meter, manufactured by Felix Instruments Applied Food Science, is a general device for fresh produce. The F-750 can non-destructively measure SSC, DM, titrable acidity, and color. Individual readings can be generated within 4-6 seconds.

The F-750 also has a starter model for dry matter estimation for sweet cherries. The model was provided by the Agriculture and Agri-Food Canada and was created in 2017 by Dr. Peter Toivonen, Mr. Adrian Batista, and Ms. Brenda Lannard of the Summerland Research and Development Centre.

Further models can be easily created with the help of accompanying instructions.

Harvest Indices

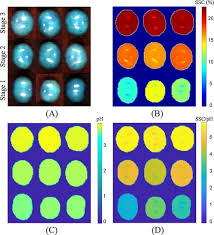

Figure 1: Li et al, 2018. (Image credits: https://doi.org/10.1016/j.postharvbio.2018.05.003)

Harvesting at the correct time is crucial to ensure that the fruits meet market standards. Fruits that are underripe or overripe will not have the desired quality attributes. Hence, predicting the harvest date can improve yield quality.

Cherry is non-climacteric and won’t ripen after harvest. It can, however, age, which causes them to get softer and decay. The fruit ripens on the tree and changes texture, color, and taste. Hard, green,unripe cherries turn softer, sweeter, and become red to black.

Hence, as in all non-climacteric fruits, sugar content and color development can be used as indicators of ripening to set harvest time.

- Index of absorbance IAD can be measured by Vis-NIR spectroscopy portable devices. This index measures the amount of de-greening as ripening proceeds. Fruit color development in cherries has been correlated to anthocyanin and sugar content, so the chroma or skin color intensity is a good indicator of internal ripening processes.

- As fruits ripen, they become less sour and more sweet. The differing ratio between SSC and acidity can be used to identify the different stages of maturity in cherries. SSC is measured by degree BRIX and acidity is measured by pH. The ratio between sourness and sweetness can thus be used to set harvest time when the desired SSC/pH ratio is achieved.

NIR hyperspectral imaging based on the spectral signature of compounds can be used to estimate the levels of sugars and pH in fruits, as shown in Figure 1. However, it is challenging to miniaturize imaging technology to fit handheld devices.

Post-Harvest Quality Control

Sweet cherries used as fresh fruits have to be stored with care. Their shelf life depends on the storage temperature and humidity. The storage time for cherries is as follows:

- At room temperatures for 2-3 days

- In refrigeration at around 4oC for 14 days

- When cooled to 0oC within 36 hours, it can be stored the longest

During storage and transport, quality parameters are monitored to

- Sort spoiled fruits and cull them to maintain the quality of the batch

- Fix the price of fruits by determining the quality of the produce

Small, handheld NIR devices are valuable in all these stages, too. Some of the important quality parameters that are monitored are color, firmness, bruising, SSC, and dry matter (DM) content.

Sensory Quality

The idiom “cherry on the cake” to define anything that makes a situation perfect should show how important the appearance of the fruit is.

Consumers buying the real cherry look for perfection in color and shine. The various varieties come in an array of tempting colors from red to black.

Cherries owe their color to the pigment anthocyanin in the skin cells. It is responsible for yellow, orange, red, magenta, violet, and blue colors in fruits, vegetables, and autumn leaves.

Color development can be measured by the Index of absorbance IAD with vis-NIR spectroscopy.

Bruising

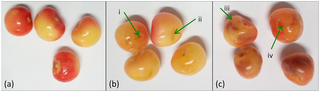

Figure 2: Detecting bruising in cherries, Shao Y, Xuan G, Hu Z, Gao Z, Liu L, 2019. (Image credits: PLoS ONE 14(9): e0222633. https://doi.org/10.1371/journal.pone.0222633)

As they age, cherries become soft and they can bruise easily due to being thin-skinned. Thus, bruising is a function of firmness in fruits.

Bruises can lead to external and internal changes. Due to bruising, there is a change in the firmness, color, and SSC content. Spots of bruising will cause the spread of enhanced decay, as shown in Figure 2.

In the early stages the changes are not easily visible to the human eye, but bruised fruits can be identified by Vis-NIR spectroscopy.

Taste and Flavor

Cherries that are firmer at harvest last longer but have less sugar content, so the taste of the fruit is affected. For this reason, sugar remains one of the most important components to test quality in storage and retailing.

- The sugars present in cherries are the soluble sugars sucrose, fructose, and glucose, as well as sorbitol, the sugar alcohol. The soluble sugars can be measured by BRIX.

- Besides sugar, the dry matter has also been tested to monitor the taste and flavor of fruits in storage. DM is as good or even better than sugar content in predicting the quality and taste of sweet cherries.

Dry matter is the total of all solids in the fruits minus its water content. In sweet cherries, 80% of dry matter is sugars, and the rest is fiber, acids, and some proteins. So, DM is a good indicator of all sugars and is, therefore, better in taste measurement than just soluble sugar content.

Both parameters can be tested for cherries in cold storage at 0oC and room temperatures. Therefore, the group recommends the use of handheld NIR devices for non-destructive quality control.

Increasing Food Security

Cherries that are harvested at the wrong time will not be of the right quality, so the chances of their post-harvest rejection are higher. Moreover, spoilage can increase when fruits are harvested late. Sorting and detecting bruised fruits can also reduce waste. So, simple NIR handheld tools that can be used in the entire supply chain can increase the yield on the farm and maintain the quality of fruits until they reach consumers. This makes production more profitable for farmers and suppliers. Also, food production becomes more sustainable and secure.

—

Vijayalaxmi Kinhal

Science Writer, CID Bio-Science

Ph.D. Ecology and Environmental Science, B.Sc Agriculture

Feature image coutesy of Niklas Bildhauer

Sources

Carlini P, Massantini R, Mencarelli F. (2000). Vis-NIR measurement of soluble solids in cherry and apricot by PLS regression and wavelength selection. J Agric Food Chem., 48(11):5236‐5242. doi:10.1021/jf000408f

Davies, A.M.C. (n.d.). An introduction to near infrared (NIR) spectroscopy. (n.d.). Retrieved, from https://www.impopen.com/introduction-near-infrared-nir-spectroscopy

Escribano, S., Biasi, W., Lerud, R., Slaughter, D., & Mitcham, E. (2017). Non-destructive prediction of soluble solids and dry matter content using NIR spectroscopy and its relationship with sensory quality in sweet cherries. Postharvest Biology and Technology, 128, 112-120. doi:10.1016/j.postharvbio.2017.01.016

Gardiner, M.A., Beyer, R., & Melton, L.D. (1993) Sugar and anthocyanidin content of two processing‐grade sweet cherry cultivars and cherry products, New Zealand. Journal of Crop and Horticultural Science, 21:3, 213-218, doi: 10.1080/01140671.1993.9513771

Li, X., Wei, Y., Xu, J., Feng, X., Wu, F., Zhou, R., . . . He, Y. (2018). SSC and pH for sweet assessment and maturity classification of harvested cherry fruit based on NIR hyperspectral imaging technology. Postharvest Biology and Technology, 143, 112-118. doi:10.1016/j.postharvbio.2018.05.003

Lu, R. (2001). Predicting Firmness And Sugar Content Of Sweet Cherries Using Near-Infrared Diffuse Reflectance Spectroscopy. Transactions of the ASAE, 44(5). doi:10.13031/2013.6421

Martín, J., Navas, M. J., Jiménez-Moreno, A. M., & Asuero, A. G. (2017). Anthocyanin Pigments: Importance, Sample Preparation and Extraction. Phenolic Compounds – Natural Sources, Importance and Applications. doi:10.5772/66892

Nagpala, E.G.L., Noferini, M., Farneti, B., Piccinini, L. and Costa, G. (2017). Cherry-Meter: an innovative non-destructive (vis/NIR) device for cherry fruit ripening and quality assessment. Acta Hortic. 1161, 491-496. doi: 10.17660/ActaHortic.2017.1161.78. https://doi.org/10.17660/ActaHortic.2017.1161.78

(n.d.). Varieties. Retrieved from https://cherries.org.au/cherries/varieties

Shao, Y., Xuan, G., Hu, Z., Gao, Z., & Liu, L. (2019). Determination of the bruise degree for cherry using Vis-NIR reflection spectroscopy coupled with multivariate analysis. Plos One, 14(9). doi:10.1371/journal.pone.0222633

Stow, J.R., Jameson, J., & Senner, K. (2004). Storage of cherries: the effects of rate of cooling, store atmosphere and store temperature on storage and shelf-life, The Journal of Horticultural Science and Biotechnology, 79:6, 941-946, doi: 10.1080/14620316.2004.11511870

Toivonen, P., Batista, A., & Lannard, B. (2017). Development of a predictive model for ‘Lapins’ sweet cherry dry matter content using a visible/near infrared spectrometer and its potential application to other cultivars. Canadian Journal of Plant Science. doi:10.1139/cjps-2017-0013

Related Products

- Felix Expansion Card

- F-751 Grape Quality Meter

- Custom Model Building

- F-910 AccuStore

- F-751 Melon Quality Meter

- F-751 Kiwifruit Quality Meter

- F-750 Produce Quality Meter

- F-751 Avocado Quality Meter

- F-751 Mango Quality Meter

- F-900 Portable Ethylene Analyzer

- F-950 Three Gas Analyzer

- F-920 Check It! Gas Analyzer

- F-960 Ripen It! Gas Analyzer

- F-940 Store It! Gas Analyzer

Most Popular Articles

- Spectrophotometry in 2023

- The Importance of Food Quality Testing

- NIR Applications in Agriculture – Everything…

- The 5 Most Important Parameters in Produce Quality Control

- Melon Fruit: Quality, Production & Physiology

- Fruit Respiration Impact on Fruit Quality

- Guide to Fresh Fruit Quality Control

- Liquid Spectrophotometry & Food Industry Applications

- Ethylene (C2H4) – Ripening, Crops & Agriculture

- Active Packaging: What it is and why it’s important