October 21, 2020 at 9:23 pm | Updated October 21, 2020 at 9:23 pm | 6 min read

Near-infrared spectroscopy can be used to control quality and monitor the manufacturing process of several kinds of cheese. The technology helps people in fine-tuning cheese production to save costs and avoid waste. Many devices proposed in the last seven decades have not been able to meet industry standards, mainly because they are destructive. Thus, both portable and desktop near-infrared sensors provide a novel alternative.

Near-Infrared Spectroscopy

Near-infrared (NIR) spectroscopy is widely used to analyze quality of fresh produce. Among the animal products, cheese production is one of the areas where NIR is most used.

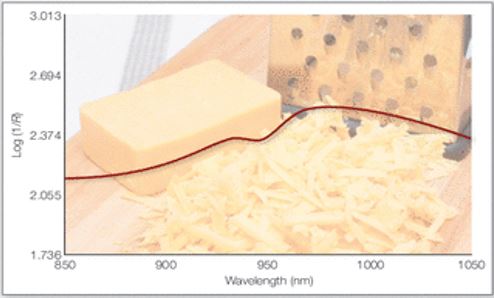

NIR is the part that lies next to the visual spectrum of light. NIR spectroscopy directs a beam of light at the sample, which is then absorbed, transmitted, or reflected. The interaction of NIR light with the chemical compounds can vary. Some can be more accurately measured by absorption, while yet others can be identified and quantified by the light they transmit or reflect, as shown in Figure 1.

Subscribe to the Felix instruments Weekly article series.

By submitting this form, you are consenting to receive marketing emails from: . You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact

Research is necessary to study how each material will react to NIR. For example, NIR reflectance can more accurately evaluate moisture content in cheese than transmittance.

The parameters that are measured by NIR in cheese making are fat, moisture, protein, salt content, and dry matter.

Figure 1: “Transmission NIR spectrum (850-1050 nm) of a Cheddar cheese,” Holroyd 2011 (Image credits: https://doi.org/10.1255/nirn.1264)

In the case of cheese, NIR can control not just the quality of the product, but also be a useful tool in the manufacturing process. Since NIR can penetrate deeper in a sample, it is preferred over the mid-infrared spectrum.

Cheese Production

Cheese is produced from cow, buffalo, sheep, and goat milk. The milk can be raw, homogenized, or pasteurized. Many steps are involved in making cheese. The actions, duration, or order of cheese production can depend on the type of cheese.

Some principles that are often used are standardizing milk, coagulating, pressing, salting, aging, etc. NIR can be successfully used in all these stages and more.

Standardize Milk

The chemical composition of milk used to make cheese has to be standardized to ensure that the ratio of proteins to fat is optimum. Fat content is one of the main defining factors of a cheese’s flavor. While protein content, especially casein, determine the coagulation of milk.

Hence, the content of fat and protein and their ratio is crucial to the whole process of cheese making. The protein to fat ratio will vary depending on the cheese. It is 1.15 for Baby Gouda and 0.86 for Brie. Since fat and protein can be easily identified and quantified by NIR, producers can check each batch of milk. The ratio can be varied by adding skim milk powder or by mixing milk from different herds.

Milk Renneting

Coagulation of milk is the first step in cheese making. It is possible to coagulate milk with enzymes, acids, or heat-acid treatment.

Renneting coagulates milk by using an enzyme Chymosin. There are many variables involved, such as temperature, rennet concentration, fat content, and salt concentrations, which can influence and change the duration of the process.

Once the milk has coagulated, the solid curd particles must be separated from the whey in a process called cutting.

The cutting time is crucial and can affect the yield, fat content, and whey fat losses. Early cutting before coagulation is complete will reduce yield. Delaying it too long will make the curds too firm and increases yield by having too much water, which affects quality. The optimum cutting time gives good quality and quantity of cheese.

Previously, traditional skills of personnel or a predetermined time were used to decide when to cut the curds.

NIR spectroscopy is more suitable because it can provide information on the chemical and physical features of the cheese. It is non-destructive and gives rapid results. New portable instruments that can be used in-line or manually can take numerous measurements to track renneting and coagulum strength.

With the help of NIR spectroscopy, scientists have been able to identify that the rennet occurs in the following three stages, regardless of temperature and fat content: the liquid milk phase, the transition phase, and the solid phase. Each step has a different spectral profile. The difference in temperature and fat content can vary the profiles of the three phases. Moreover, the profiles of milk that fail to clot properly differ entirely. So, it is possible to identify failures in the process from the beginning to the end.

When the third and solid-phase parameters are reached, manufacturers can decide to stop renneting. The NIR method is far superior to visual observations that were used traditionally. It also avoids whey fat losses and retains the right moisture content in the cheese.

NIR is more useful in determining the cutting time for coagulation of cow milk than for sheep milk.

Other Processing Steps

After coagulation, the steps will vary depending on whether the product is a hard cheese or soft cheese.

Very soft cheese, like mozzarella, is removed and treated in hot water or acid after which they are ready for sales.

To make soft cheese, like Brie, the curds are hung to remove water. Then, it is treated in a salt solution and sprayed with fungal spores. The cheese is aged until it is covered by fungal growth.

In the case of hard cheese, like gouda, the curd is separated into blocks and piled to allow more water to drain away slowly. In many cases, the fermentation is allowed to proceed to get the desired pH. Salt is added to many varieties before pressing or later on the rind. It removes more water, improves taste, and prevents spoiling of the cheese. The cheese is then pressed, usually into circular shapes. They are then stored for varying lengths of time, depending on the variety of the cheese.

NIR spectroscopy can monitor the process before pressing, after pressing, and after salt treatment to identify the point when they reach the best moisture and fat content.

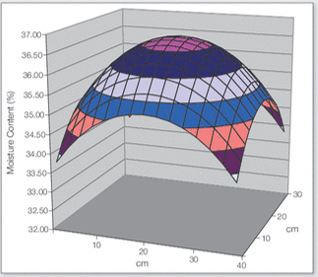

The composition of each block of cheese will not be uniform. Moreover, it will alter during the production process as it ages. Moisture content, for example, varies at different depths of the block. All these changes have been monitored precisely using NIR spectroscopy; see Figure 2.

Aging is also tracked by physical features, like color, that NIR can examine.

Figure 2: Difference in moisture content in a 20 kg block of cheese, Holroyd 2011. (Image credits: https://doi.org/10.1255/nirn.1264)

Branding and Geographical Origin

Each cheese type should have recommended amounts of proteins, fat, and moisture. Each country also has its own specifications.

Hard cheese, like cheddar, has 31% fat and 39% water. Mozzarella in Canada has 20% fat and 52% moisture, while in the US it has 22% fat and 50% moisture. In Italy, some Mozzarella varieties can have 45% fat.

NIR is efficient in differentiating between cheese varieties and ascertaining that they meet the standards required in a country. Also, because of the difference in the chemical composition within a single cheese type produced in different parts of the world, it is easy to find where they originated. Cheese from each country has its own known NIR profile.

Quality Control

The quality of cheese can be controlled at any point in the supply chain. Cheese is widely exported around the world and undergoes long transportation and storage periods. Many have shelf lives that run into months. So, NIR is a valuable tool in these cases as well.

NIR Tools

Many NIR based tools are on the market and can be used to aid in cheese making and quality control of the processed products. One such example is the F-750 Produce Quality Meter. Though it was produced for quality control in fruits and vegetables, it can be used for cheese after models are created. It is a small handheld device that gives individual, accurate readings within minutes. It is also affordable and the right choice for retailers who can test fresh produce and meat, besides cheese.

—

Vijayalaxmi Kinhal

Science Writer, CID Bio-Science

Ph.D. Ecology and Environmental Science, B.Sc Agriculture

Feature image courtesy of Paul Asman and Jill Lenoble

Sources

Adamopoulos, K. G., Goula, A. M., & Petropakis, H. J. (2001). Quality Control During Processing of Feta Cheese—NIR Application. Journal of Food Composition and Analysis, 14(4), 431–440. doi: 10.1006/jfca.2000.0976

Castillo, M. (2010). Cheese Making: Cutting Time Prediction. Encyclopedia of Agricultural, Food, and Biological Engineering, Second Edition, 218–224. doi: 10.1081/e-eafe2-120040365

Grassi, S., Strani, L., Casiraghi, E., & Alamprese, C. (2019). Control and Monitoring of Milk Renneting Using FT-NIR Spectroscopy as a Process Analytical Technology Tool. Foods, 8(9), 405. doi: 10.3390/foods8090405

Holroyd, S. (2011). NIR Analysis of Cheese—A Fonterra Perspective. NIR News, 22(6), 9–11. doi: 10.1255/nirn.1264

Milk Coagulation. (n.d.). Retrieved from https://www.uoguelph.ca/foodscience/book-page/milk-coagulation

Mozzarella. (n.d.). Retrieved from https://www.cheese.com/mozzarella/

Nicolau, N., Buffa, M., O’callaghan, D. J., Guamis, B., & Castillo, M. (2015). Estimation of clotting and cutting times in sheep cheese manufacture using NIR light backscatter. Dairy Science & Technology, EDP sciences/Springer, 2015, 95: 495-507. 10.1007/s13594-015-0232-7. hal-01312523

Pillonel,.L., Luginbühl, .W., Picque, .D. et al. Analytical methods for the determination of the geographic origin of Emmental cheese: mid- and near-infrared spectroscopy. Eur Food Res Technol 216, 174–178 (2003). https://doi.org/10.1007/s00217-002-0628-5

Standardization of milk for cheese making. (n.d.). Retrieved from https://www.uoguelph.ca/foodscience/book-page/standardization-milk-cheese-making

Zou, Q., Fang, H., Zhang, W., and He, Y. (2011). Application of Near Infrared Spectroscopy (NIR) for Evaluating Cheese Quality. Guang pu xue yu guang pu fen xi = Guang pu 31:2725-9. https://doi: 10.3964/j.issn.1000-0593(2011)10-2725-05

Related Products

- Felix Expansion Card

- F-751 Grape Quality Meter

- Custom Model Building

- F-910 AccuStore

- F-751 Melon Quality Meter

- F-751 Kiwifruit Quality Meter

- F-750 Produce Quality Meter

- F-751 Avocado Quality Meter

- F-751 Mango Quality Meter

- F-900 Portable Ethylene Analyzer

- F-950 Three Gas Analyzer

- F-920 Check It! Gas Analyzer

- F-960 Ripen It! Gas Analyzer

- F-940 Store It! Gas Analyzer

Most Popular Articles

- Spectrophotometry in 2023

- The Importance of Food Quality Testing

- NIR Applications in Agriculture – Everything…

- The 5 Most Important Parameters in Produce Quality Control

- Melon Fruit: Quality, Production & Physiology

- Fruit Respiration Impact on Fruit Quality

- Guide to Fresh Fruit Quality Control

- Liquid Spectrophotometry & Food Industry Applications

- Ethylene (C2H4) – Ripening, Crops & Agriculture

- Active Packaging: What it is and why it’s important