September 10, 2020 at 2:27 am | Updated September 10, 2020 at 2:27 am | 6 min read

NIR spectroscopy can be used in the pulp industry at many critical points for the qualitative and quantitative analysis of the chemical composition of feedstock and pulp. The precise and rapid estimation methods make predictions of a variety of quality parameters that help in raw material selection, processing, and product control. Several types of desktop and online tools are already in use and make the analysis process chemical free.

Wood Pulp Uses

Wood pulp is traditionally used for making paper. It can also be used to manufacture viscos fiber, a type of cellulosic fiber used to make textiles.

Wood biomass is made up of 95% cellulose, as well as hemicellulose and lignin.

Subscribe to the Felix instruments Weekly article series.

By submitting this form, you are consenting to receive marketing emails from: . You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact

Near-Infrared spectroscopy (NIRS) can be a feasible alternative to traditional analytic methods used throughout the supply chain in the pulp industry.

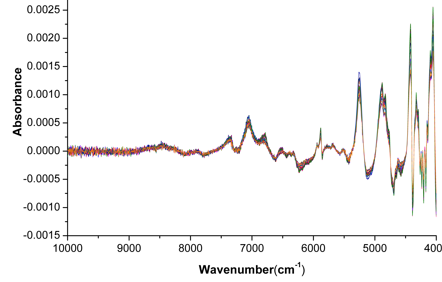

NIRS is useful due to the interaction of light with bonds formed between hydrogen and other elements in biocompounds. Based on their chemical composition, bio compounds will absorb, reflect, and transmit different amounts of light. Biocompounds will differ in their reaction to wavelengths of light, even within the NIR, so the correct wavelength to analyze them must be chosen. For example, Figure 1 shows how cellulose in pulp reacts with NIR at various wavelengths.

Figure. 1.: Cellulose prediction in pulp, Zhou et al. 2018. (Image credits: BioRes. 13(3), 6122-6132.)

Some of the main uses of NIR spectroscopy in the pulp industry are to

- predict pulp yield and quality of wood,

- monitor pulping processes,

- and estimate pulp quality.

To understand the use of NIRS, it is necessary to be aware of how pulp is formed.

Kraft pulping is the conversion of wood biomass into pulp that mainly consists of cellulose. Pulping involves the combination of mechanical and chemical processes.

The Kappa number is used as a parameter in the pulp industry to measure the amount of lignin in the wood pulp. It is also a measure of the amount of chemicals required to bleach the pulp to a given degree of whiteness.

Predicting Pulp Yield and Quality Of Wood

The application of NIRS in the pulp industry starts at the plantations. Many countries are major producers of pulp, and they need to evaluate the wood in tree plantations for profitability.

The following estimations are necessary:

- Pulp yield: Determination to a given kappa number can be made of pulp yield based on xylan and lignin content. Estimations can be also done on unfelled trees.

- Basic density: Though density is not a chemical parameter, the relationship of the three main components (cellulose, hemicellulose, and lignin) with density is used to get the wood density with the aid of chemometrics.

- Chemical properties: Of all the components, cellulose and lignin content are the most important ones and can be estimated by NIRS

The traditional methods of finding these parameters are tedious, especially for determining pulp yield, where industrial pulping techniques of cooking the chips have to be replicated.

Lignin content estimation requires titrations, which can take 20-30 minutes even in automated or semi-automated methods. Cellulose content is traditionally estimated using wet chemistry methods. All methods cause pollution, due to the use of chemicals, and are time consuming.

NIRS can replace these diverse methods, and give rapid results regarding estimated pulp yield and quality.

Quality of Wood Chips

The fluctuating quality of incoming wood is a challenge for the pulp industry as it affects the chemical recovery process. Several aspects can be controlled by NIRS:

- Quality: Pulp processors like to know the quality of their wood, including lignin content and moisture content. Quality estimation is important, especially when the wood chips come from different species and are of different sizes, which is often the case. The quality of the composites has to be measured to aid decisions in the pulping process in terms of quantity of chemical use, length of the cooking process, etc. NIRS can do this in real-time and can be used in the factories.

- Origin determination: NIRS can help in differentiating the origin of wood chips in terms of species, or it can differentiate between softwood and hardwood, and heartwood from sapwood. The difference in tissue composition and the compounds can aid in this analysis.

- Pulp yield: Analyzing pulp yield is of paramount importance to pulpers and plantation owners alike.

Control and Monitoring of Pulping

Pulping first requires the wood to be digested by reactors, followed by a chemical recovery process. Both stages are important in determining the output quantity and quality and must be consistently monitored.

Wood digesters are of two types: continuous and batch reactors.

In the digesters, the wood chips are treated with hot water and chemicals to break the bonds and separate cellulose from lignin and hemicellulose. The result is pulp-fiber made of cellulose and black liquor, both of which are used in the next chemical stage.

One of the aims of the digester is delignification, which is why lignin content is controlled in feedstocks by monitoring the Kappa number of the incoming wood chips. Kappa number estimation is important due to variations in moisture content, species mix, and chip sizes of the feedstock. Continuous monitoring of the feedstock is also important if there is a transition in wood types, eg. softwoods to hardwoods, etc.

Using the information on lignin content, pulpers can adjust cooking times and recipes, as well as time the opening of inlets and outlets. The whole process has to be well timed to get the precise pulp quality desired.

Later, after the chemical recovery, pulp bleaching is also tested by Kappa number.

Fully automated titration methods to determine Kappa number work only with clean pulp that is free of black liquor or if the pulp is partly or entirely bleached. Therefore, NIRS can be very useful, as it can be used online at any time of the process.

NIRS is also used online by many pulpers to measure moisture content during the process.

Final Pulp and Paper Quality

The final quality of both pulp and paper can also be controlled by NIRS.

Pulp Quality

The final pulp sheet that is produced also has its quality controlled easily by NIRS, once again by using Kappa number. This is one of the final steps during the inspection of the pulp sheets.

Kappa number can be a procurement criterion that pulp producers must meet. In these cases, manual subjective testing is not good enough. The precise and objective measurements made by NIRS are being increasingly used to satisfy customers.

Paper Quality

In the case of paper, many fillers are added to the cellulosic pulp that will determine its end appearance, surface, and brightness. The fillers can be natural, like calcium carbonate, or synthetic minerals, like talc and titanium dioxide.

Paper is graded depending on the amount of fillers they contain. Food grade paper, such as milk cartons and tissue papers, have no fillers, while printing paper can contain between 5-30% fillers. The trend nowadays is to add more and more fillers.

There are many reasons to add fillers while manufacturing paper:

- Cost of raw materials: Fillers are cheaper and bring paper production costs down.

- Reduction in energy use: The drying time is shorter when fillers are used, so it reduces energy use and costs.

- Alteration of properties: Fillers change brightness, strength, smoothness, opacity, stability, and print quality.

- Burn Rate: Fillers determine burn rate of paper and are important in the papers used to make cigarettes.

Many of these chemical properties of paper, such as lignin content, can also be measured by Kappa number, brightness, coatings, fillers, and their identity.

NIRS Tools

There are several NIRS tools available on the market. Popular portable iterations, like the Felix F-750, are available, as well as desktop and online variants. Any industry that works with wood, plant, or animal production can benefit from the use of NIRS throughout the supply chain to control and improve the quantity and quality of products.

—

Vijayalaxmi Kinhal

Science Writer, CID Bio-Science

Ph.D. Ecology and Environmental Science, B.Sc Agriculture

Feature image courtesy of Kate Ter Haar

Sources

Antti, H., Sjöström, M., and Wallbäcks, L. (1996). Multivariate calibration models using NIR spectroscopy on pulp and paper industrial applications. Journal of Chemometrics, 10(5-6), 591-603. doi:10.1002/(sici)1099-128x(199609)10:5/63.0.co;2-l

Hubbe, M. A., and Gill, R. A. (2016). “Fillers for papermaking: A review of their properties, usage practices, and their mechanistic role,” BioRes. 11(1), 2886-2963. NIR spectroscopy: A paradigm shift in pulp properties measurements. (2019, August 19). Retrieved August 22, 2020, from https://www.pulpandpapercanada.com/nir-spectroscopy-a-paradigm-shift-in-pulp-properties-measurements-1100000084/

Skvaril, J., Kyprianidis, K., & Avelin, A., & Odlare, M., and Dahlquist, E. (2018, September). Application of Near Infrared Spectroscopy for Rapid Characterization of Feedstock Material in Pulp and Paper Industry. Paper presented at the 17th International Conference on Near Infrared Spectroscopy – Book of Abstracts. Retrieved from https://proceedings.science/nir-abstracts/papers/application-of-near-infrared-spectroscopy-for-rapid-characterization-of-feedstock-material-in-pulp-and-paper-industry#

Tsuchikawa, S., and Kobori, H. (2015). A review of recent application of near infrared spectroscopy to wood science and technology. Journal of Wood Science, 61(3), 213-220. doi:10.1007/s10086-015-1467-x

Tyson, J.A., Schimleck, L.R., Aguiar, A.M., Abad, J.I.M., Rezende, G.D.S.P., and Filho, O.M. (2012) Development of near infrared calibrations for physical and mechanical properties of eucalypt pulps of mill-line origin. J Near Infrared Spectrosc 20:287–294

Zhou, C., Han, G., Gao, S., Xing, M., Song, Y., and Jiang, W. (2018). “Rapid determination of cellulose content in pulp using near infrared modeling technique,” BioRes. 13(3), 6122-6132.

Related Products

- F-751 Grape Quality Meter

- Custom Model Building

- F-910 AccuStore

- F-751 Melon Quality Meter

- F-751 Kiwifruit Quality Meter

- F-750 Produce Quality Meter

- F-751 Avocado Quality Meter

- F-751 Mango Quality Meter

- F-900 Portable Ethylene Analyzer

- F-950 Three Gas Analyzer

- F-920 Check It! Gas Analyzer

- F-960 Ripen It! Gas Analyzer

- F-940 Store It! Gas Analyzer

Most Popular Articles

- Spectrophotometry in 2023

- The Importance of Food Quality Testing

- NIR Applications in Agriculture – Everything…

- The 5 Most Important Parameters in Produce Quality Control

- Melon Fruit: Quality, Production & Physiology

- Fruit Respiration Impact on Fruit Quality

- Guide to Fresh Fruit Quality Control

- Liquid Spectrophotometry & Food Industry Applications

- Ethylene (C2H4) – Ripening, Crops & Agriculture

- Active Packaging: What it is and why it’s important