December 30, 2025 at 10:24 pm | Updated December 30, 2025 at 10:24 pm | 6 min read

- Vegetable growers should monitor ethylene, as it can cause stunting, defects, delayed flowering, and a significant reduction in yield.

- The extent of damage depends on the species, greenhouse type, temperature, ethylene concentration, exposure duration, and plant stage.

- Ethylene concentrations in greenhouses and indoor environments must be below 20 nmol⋅mol−1 (0.020 ppm or parts per million) to maintain proper plant growth and yield.

- Proper maintenance of equipment, ventilation, removal of dead and damaged plant parts, air monitoring, and scrubbing are some steps to control ethylene.

Ethylene is a phytohormone produced by plants throughout their life cycle to promote processes from germination. Yet, its impacts during the growing stages are also significant enough to earn it the status of the “death hormone” for greenhouse crops. Find out how and why the valuable ethylene turns harmful for greenhouse growers in this article.

Ethylene Gas

Ethylene (C2H4) is a colorless and odorless gas that plants produce naturally. It is lighter than air and accumulates in higher spaces of a room.

According to Hudelson et al. (2023), ethylene concentration in the atmosphere over open fields does not exceed 5 nmol⋅mol−1 (0.005 ppm or parts per million). Low ethylene concentration is beneficial for greenhouse growers in many ways.

Subscribe to the Felix instruments Weekly article series.

By submitting this form, you are consenting to receive marketing emails from: . You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact

- Growth: Ethylene promotes germination, tuber sprouting, and stem elongation. Low amounts are also necessary for increasing leaf area.

- Flowering: Ethylene is necessary for flower development, and its activity increases after anthesis; its signaling is involved during pollination.

- Fruit development and ripening: The hormone is also responsible for flower corolla senescence, thereby allowing fruit development. In climacteric fruits, it is needed for ripening in plants and is used for artificial ripening in postharvest ripening rooms.

- Stress response: Plants produce ethylene when stressed, starting decay or senescence. Ethylene induces organ senescence in leaves and flowers, allowing plants to recycle crucial components and nutrients from aged and stressed parts of the plant.

Growers leverage ethylene’s properties to increase lateral branching, control the initiation of flowering as needed, or remove flowers.

However, in enclosed spaces with limited circulation, such as greenhouses or indoor farming, ethylene can accumulate to more than 100 nmol.mol-1 due to a lack of ventilation. As ethylene concentration increases, the damage it causes also surges. No other air pollutant has as detrimental an impact as ethylene, so it needs to be controlled.

Factors influencing the ethylene effect

Ethylene damage symptoms depend on the following factors:

- Sensitivity: Species differ in their sensitivity to ethylene.

- Temperature: Air temperature influences ethylene production in plants. Ethylene production declines below 11 °C and above 37 °C. However, low-temperature stress in chilling-sensitive plants can increase ethylene production.

- Plant development: The stage of plant development is also vital, and seedling stages are the most vulnerable to ethylene, followed by flowering.

- Type of greenhouse: A Polyhouse is more airtight than a glass greenhouse, and so the former has higher ethylene accumulation.

- Ethylene exposure: The concentration of ethylene in the air and the duration of exposure produce different symptoms and will also determine the extent of damage.

Ethylene Damage Symptoms

Elevated ethylene levels can result in abnormal growth and affect flower and fruit development, reducing yield.

The harmful effects of ethylene on vegetative growth and flower and fruit development have been studied in greenhouse fresh produce crops. According to Gibson et al. (1999), the effects vary based on concentration as follows:

- From 0.001 to 0.01 ppm, ethylene has little effect

- At 0.01 to 0.1 ppm, ethylene damage symptoms begin to appear

- Between 0.1 ppm and 1 ppm of ethylene, moderate effects on plants are seen

- Concentrations of 1 ppm to 10 ppm are considered very damaging and produce the most negative effect.

Exposure to low ethylene concentrations can cause various damages:

- Growth and flowering: Chronic exposure to 25 to 200 parts per billion (ppb) ethylene over weeks and months can occur in winter, leading to stunted growth, malformations, flower bud abortion, and smaller flowers.

- Leaf yellowing: Leaves can develop chlorosis, turn yellow, and eventually brown and die. Since this symptom can result from nutrient deficiencies and diseases, causes can be misdiagnosed, and ethylene effects will continue unhindered. This damage is more easily assigned to ethylene when higher leaves or higher plants are affected, as the hormone is lighter than air and accumulates near the top.

- Epinasty: This is the downward growth of petioles, giving the appearance of drought-struck plants. However, epinasty occurs in well-watered plants. Tomatoes are particularly susceptible to epinasty that occurs at very low ethylene levels.

Exposure to higher ethylene concentrations, starting at 1 ppm, when the hormone is fully biologically active, damages plants within hours or days. Hence, it is easier to identify ethylene as the causal factor in these acute damages. It causes leaf, bud, and petal shedding, leaf yellowing, and rapid flower aging.

Impact on yield

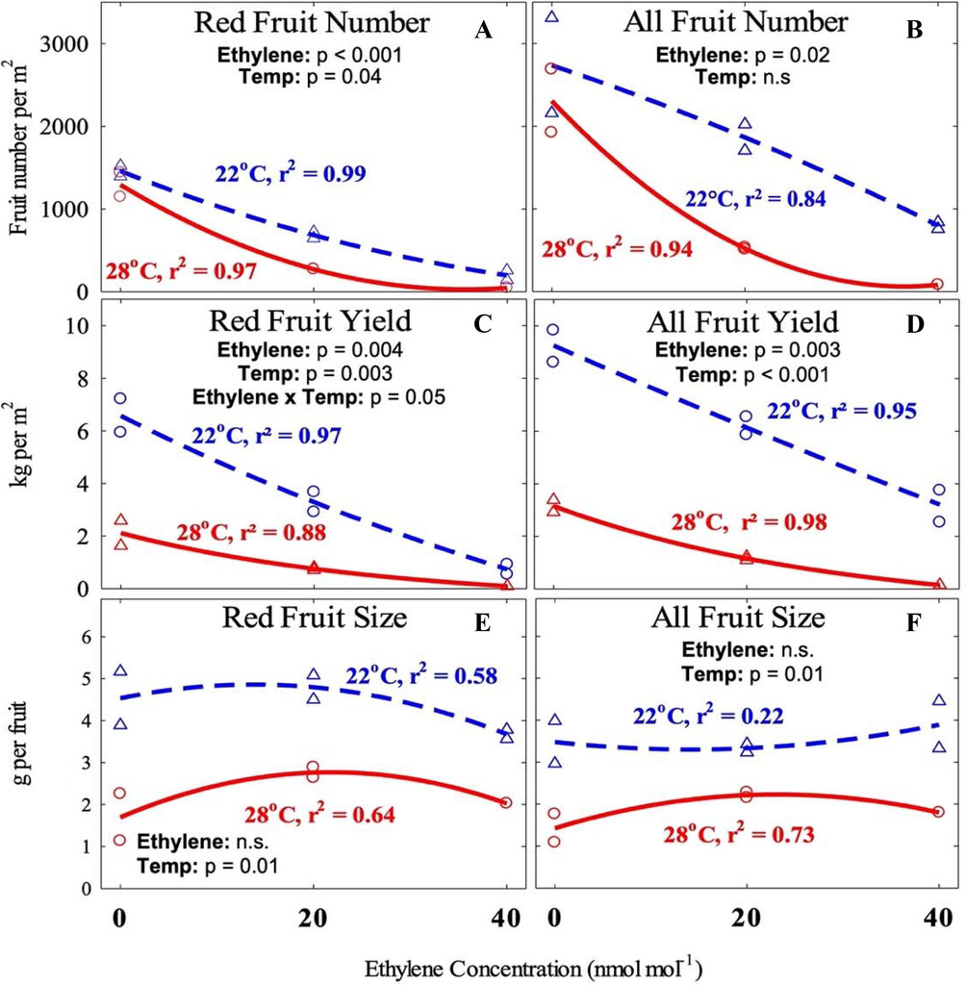

The impact on yield is greater than on vegetative growth. For example, in an experiment on tomatoes grown in greenhouses, the effect on vegetative growth alone was minimal, at only 10% lower, even at ethylene concentrations up to 40 nmol⋅mol−1 (0.040 ppm). However, the yield was reduced to 11% and 4% of the control at 22 °C and 28 °C, respectively. See Figure 1.

In most species, yield is affected when ethylene concentrations reach 20 nmol⋅mol−1 (0.020 ppm), but in ethylene-sensitive species, yield declines begin at 10 nmol⋅mol−1 (0.010 ppm).

Hence, ethylene concentrations in greenhouses and indoor environments must be below 20 nmol⋅mol−1 (0.020 ppm) to maintain proper plant growth and yield. In greenhouses, healthy plants can continuously produce ethylene, raising concentrations to 1000 nmol⋅mol−1 (1 ppm).

Each year, greenhouses report significant losses due to ethylene. These losses vary by crop, location, season, and management practices. Though exact data on economic losses is not available, because reports focus on damage types, growers find it challenging to make a profit. Growers have a low ROI due to yield loss, reduced vegetable quality, and additional operational expenses, such as scrubbers and filters to control ethylene.

Recovery from ethylene

In many cases, plants do recover when ethylene levels are controlled; however, this depends on the stage and extent of damage.

- Ethylene damage to seedlings may require replanting the entire crop.

- Plants with moderate damage could recover and continue growth and flowering in 1-2 weeks.

- New growth may appear after extensive damage, but delayed crops can affect marketability.

Figure 1: “Effect of ethylene and temperature on (A and B) fruit number, (C and D) fruit yield, and (E and F) fruit size at harvest on day 106 for tomatoes. The red fruit number, total fruit number, and yield declined significantly with increasing ethylene. There was no significant effect of ethylene on red fruit size but increasing temperature significantly decreased fresh weight per red fruit. Temperature influenced only total yield,” Hudelson et al. 2023. (Image credits: HortScience 58, 3; 10.21273/HORTSCI16901-22)

Eliminating Ethylene

Growers must identify the sources of ethylene in greenhouses to eliminate their generation. Ethylene is produced naturally by plants and from artificial sources:

- Plant sources: Ethylene is continuously generated by plants throughout their lifecycle. During ripening, the generation levels are higher. Plant parts damaged by insects and diseases can also produce ethylene as a stress response. Any dead, decaying, and rotting plant material from weeds and spent flowers will also produce ethylene.

- Artificial sources: The most common artificial sources of ethylene in a greenhouse are malfunctioning heating systems, water heaters, exhaust from combustion engines (blowers and trimmers), leaky gas lines, carbon dioxide burners, and cigarettes.

Ethylene has an autocatalytic or auto-generation property; that is, even a small amount of ethylene can trigger the production of more ethylene in plants. Since ethylene is a gas, it moves freely and rapidly in the greenhouse, spreading damage throughout a tight structure, especially in winter, unless it is removed.

Preventing ethylene losses

Economic losses from ethylene can be minimized by following these steps.

Heating Units: These are the foremost source of ethylene in a greenhouse. Regular maintenance of heaters, vent stack, distribution tubes, ventilation, and fuel pipes can help eliminate or minimize malfunctions that affect ethylene control.

Segregation: Keep exhaust-producing trucks and soil-mixing machines away from the area where plants grow.

Oxygen intake: Ensure that the entire greenhouse has proper ventilation to remove any accumulated ethylene and let in fresh air. Without a fresh oxygen supply replenished every 2 to 3 hours, burners shut off and begin producing ethylene.

Work through a checklist: Growers can maintain a list and regularly check machines and equipment that can produce ethylene for malfunctions or leaks.

Proper housekeeping: Since ethylene is released by injured and decaying plant material, immediate and proper sanitary measures should be taken.

Growers should monitor the air for ethylene accumulation and be ready to scrub and filter the air, especially in winter when ventilation does not remove all ethylene.

Monitoring Ethylene Levels

Monitoring the air for ethylene continuously, using fixed equipment or portable gas analyzers, can help growers identify hormone spikes. They can take corrective measures to prevent the development of symptoms that can harm marketability. Felix Instruments Applied Food Science produces both fixed (AccuStore) and portable tools (The F-901 AccuRipe). Fixed tools are used in extensive facilities for continuous, automated monitoring and data collection across many rooms. Portable tools are suitable for smaller units and spot checks. Such tools can ensure there is no gap in the efficient management of ethylene in high-value horticultural crops.

Contact us at Felix Instruments Applied Food Science to find out more about our tools and how we can help in greenhouse agriculture.

Soucres

Gibson, J.L., Whipker, B.E., Blankenship, S., et al. (1999). Ethylene: Sources, Effects, and Prevention for Greenhouse-Grown Crops. North Carolina Flower Growers’ Bulletin, 44 (5). Retrieved from https://www.researchgate.net/publication/242457319_Ethylene_Sources_Symptoms_and_Prevention_for_Greenhouse_Crops

Hudelson, T. J., Westmoreland, F. M., & Bugbee, B. (2023). Elevated Atmospheric Ethylene and High Temperature Independently Inhibit Fruit Set But Not Vegetative Growth in Tomato. HortScience, 58(3), 247–253. https://doi.org/10.21273/HORTSCI16901-22

Jones, M., & Ling, P. (2012, October 29). Better crops- Preventing ethylene damage in the production greenhouse. Retrieved from

https://www.greenhousemag.com/article/gm1112-crops-preventing-ethylene-damage/

Related Products

- F-751 Grape Quality Meter

- Custom Model Building

- F-910 AccuStore

- F-751 Melon Quality Meter

- F-751 Kiwifruit Quality Meter

- F-750 Produce Quality Meter

- F-751 Avocado Quality Meter

- F-751 Mango Quality Meter

- F-900 Portable Ethylene Analyzer

- F-950 Three Gas Analyzer

- F-920 Check It! Gas Analyzer

- F-960 Ripen It! Gas Analyzer

- F-940 Store It! Gas Analyzer

Most Popular Articles

- Spectrophotometry in 2023

- The Importance of Food Quality Testing

- NIR Applications in Agriculture – Everything…

- The 5 Most Important Parameters in Produce Quality Control

- Melon Fruit: Quality, Production & Physiology

- Fruit Respiration Impact on Fruit Quality

- Guide to Fresh Fruit Quality Control

- Liquid Spectrophotometry & Food Industry Applications

- Ethylene (C2H4) – Ripening, Crops & Agriculture

- Active Packaging: What it is and why it’s important