September 2, 2025 at 4:11 pm | Updated September 2, 2025 at 4:11 pm | 7 min read

- Ethylene is a natural phytohormone produced by plants and climacteric fruits, but also exists in the supply chain through anthropogenic sources.

- Ethylene accelerates unplanned ripening processes, causes decay, and increases susceptibility to physiological problems and pathogens.

- The effects of ethylene depend on fruit maturity stage, species, cultivars, the concentration and exposure duration of the gas, and environmental factors.

Ethylene gas is beneficial and essential when used in a controlled manner. Still, unintentional exposure can result in loss of quality, decay, and diseases that shorten the shelf life of fruits. To manage ethylene, it is necessary to understand its sources and their effects on various fruits and cultivars in the wide range of conditions that exist in a supply chain.

What is Ethylene Gas?

Ethylene is a phytohormone produced by plants that is a gas at room temperature and one atmosphere pressure. It is a simple hydrocarbon (C2H4) that influences many processes, including germination, growth, development, and defense against stresses. Its economic importance arises from its role in postharvest ripening and senescence of fresh produce and ornamental crops.

Ethylene has a significant impact on shelf life and regulates many physiological functions because it is very reactive and is involved in processes, such as:

Subscribe to the Felix instruments Weekly article series.

By submitting this form, you are consenting to receive marketing emails from: . You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact

- chemical cleavage– splitting the chemical bonds in a compound

- modification– changes a chemical’s structure or composition

- absorption– the gas can be absorbed chemically or physically by other compounds.

- Adsorption – the gas adheres to surfaces.

Ethylene concentrations as low as 0.001 μL/L of air or one part per billion (ppb) are physiologically active.

Many of the effects are beneficial and necessary for the development of fruit and its quality when used in controlled conditions. However, unintentional exposure to even trace levels of ethylene during storage and shipping can be detrimental, and it is the primary cause of loss of fruit quality and marketability. Ethylene is responsible for 10-80% of the losses in fruit and vegetable production.

Ethylene’s effects on postharvest fruit physiology and storage depend on the fruit species and cultivar, as well as pre-harvest conditions, ethylene concentration, exposure duration, environmental temperature, and relative humidity during storage and shipping.

Controlling ethylene synthesis, absorption, adsorption, and oxidation during the postharvest period, particularly during handling and distribution, can mitigate its effects.

Detrimental Effects of Ethylene

Ethylene gas levels, ranging from a few parts per billion (ppb) to parts per million (ppm), can reduce the vitality, quality, and lifespan of fruits. High concentrations of ethylene later in fruit development can cause premature aging, decay, scald, brown spots, unpleasant odors, mold, discoloration of both peel and pulp, bitterness, and loss of color. These symptoms occur due to accelerated loss of fruit quality, overmaturity of fruits, premature decay, spoilage, increased susceptibility to physiological disorders and pathogens during the postharvest phase.

Two sources of ethylene are harmful to fruits: endogenous and exogenous.

- Endogenous ethylene: The gas can be produced endogenously through biosynthesis by plants. Endogenous ethylene production is a complex process that can be triggered by signals during maturation and as a response to oxidative stress due to physiological injury, chemicals, and foodborne pathogens.

- Exogenous ethylene: External and anthropogenic sources include the combustion of stubble, straw, or fuel in vehicles and machines, smoke, plastics, and adjacent crops, and can accumulate in post-harvest facilities.

Ethylene can trigger or promote several processes, such as ripening, a hike in respiration rate, senescence, and increased sensitivity to pathogens, all of which reduce shelf life. These mechanisms are discussed below.

Unintentional Ripening

Exogenous ethylene gas application post-harvest, when intentional, helps produce ready-to-eat climacteric fruits when demand is high. However, unintentional exposure of fruits to ethylene can be detrimental to the quality and shelf life of climacteric and non-climacteric fruits.

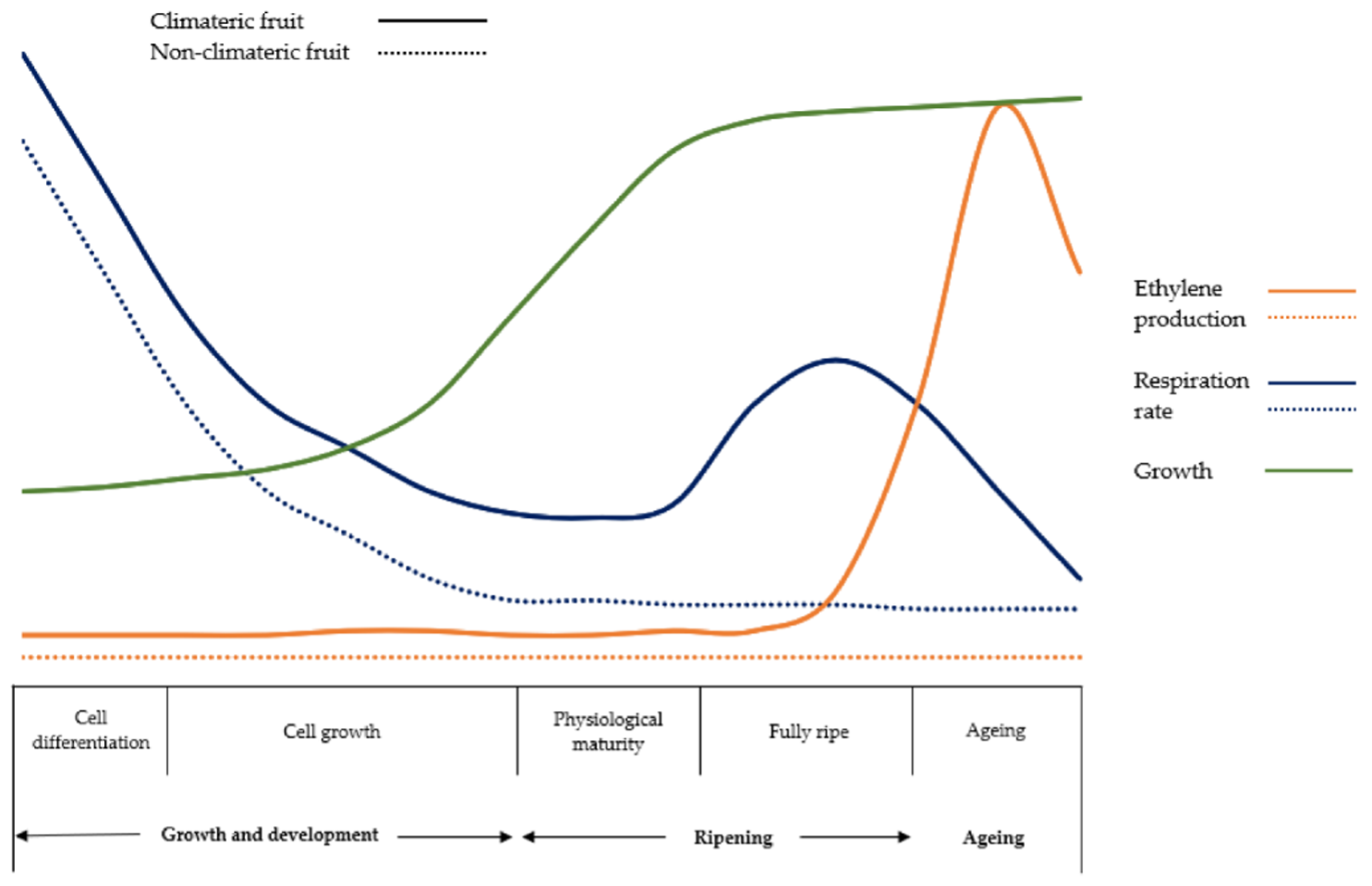

Climacteric fruits: The climacteric fruits, such as apples, mangoes, bananas, and avocados, undergo preclimacteric and climacteric phases. During the preclimacteric phase, the fruits are firm, and respiration and ethylene production rates are low (see Figure 1). Fruits are harvested at this stage, when they are physiologically mature but still unripe, allowing for more time for transportation and storage. Controlling external sources of ethylene will prolong this phase. Exposure to external ethylene gas of < 0.1 to 1.0 μL L (or 100 ppb to 1 ppm) at this stage triggers the autocatalytic endogenous production of the phytohormone within the fruits to accelerate climacteric ripening. Ripening that occurs early in the supply chain can lead to overripe fruits, which are soft, prone to bruising, and damaged during handling and shipping. Removing the exogenous ethylene stops the acceleration and ripening returns to preexposure levels. Controlling ethylene levels can increase shelf life, while higher ethylene levels will reduce it.

Non-climacteric fruits: Although ethylene is not necessary for the ripening of non-climacteric fruits, it is used commercially for degreening citrus, allowing the fruit to acquire the desired quality characteristics. When citrus is exposed to external ethylene, unintentionally, along with degreening, the negative impact on other quality parameters reduces its shelf life.

Factors such as ethylene concentrations, exposure duration, fruit sensitivity to ethylene, ripeness stage, and the external environment all contribute to determining the extent of harm caused. Ethylene-sensitive fruits must be stored in a cold, controlled atmosphere to prevent accelerated ripening before reaching retailers.

Figure 1. Respiration rate and ethylene production during postharvest, Alonso-Salinas et al. 2020. (Image credits: https://doi.org/10.3390/horticulturae10080840)

Respiration

Ethylene increases the respiration rate of fruits, triggering the physiological processes that shorten their shelf life. An inverse relationship exists between respiration rates and shelf life. The higher the fruit respiration rate, the lower the shelf life.

Increase in ethylene: An increase in respiration rate promotes autocatalytic endogenous ethylene production in fruits, which accelerates ripening at an unwanted point in the supply chain, see Figure 1. It potentially leads to fruits that are overripe, decaying, or have lower sensory and nutritional quality.

Reduced fruit quality: Increased fruit respiration leads to the consumption of oxygen, thereby lowering its levels and increasing the concentration of carbon dioxide. Proper ventilation and air circulation are essential for removing carbon dioxide and allowing oxygen to enter, to prevent anaerobic respiration, which can compromise fruit quality. Excessive fruit respiration, by itself, can cause fruit deterioration, resulting in a reduction in sensory attributes and rapid senescence. Higher fruit respiration also increases fruit transpiration, or water loss, which reduces shelf life, fruit weight, and gloss, and causes shrinking and shriveling.

Lower temperatures are suitable for lower ethylene production and respiration rates. Additionally, removing the exogenous source of ethylene allows respiration rates to return to their pretreatment levels. Controlled ethylene levels limit respiration rates, thereby delaying starch breakdown and producing firmer, less sweet fruits in storage, which extends shelf life.

Senescence

Table 1: Different fruit responses to ethylene UC San Diego

Community Health, 2017 (Credits: https://ucsdcommunityhealth.org/wp-content/uploads/2017/09/ethylene.pdf

Ethylene affects the shelf life of a wide range of fruits by causing premature senescence.

Approximately 15-20% of postharvest fresh produce losses are attributed to senescence, with ethylene being the primary trigger of this process.

Ethylene-induced senescence can have various effects, including a reduction in firmness in watermelons, degreening of vegetables (e.g., cucumbers), and the development of undesirable flavors in fruits. It also causes pulp softening and browning in apples or kiwifruits.

These effects occur in both climacteric and non-climacteric fruits, depending on their sensitivity to ethylene. In non-climacteric fruits, the changes occur due to exposure to exogenous ethylene; in climacteric fruits, both endogenous and exogenous ethylene can cause senescence. See Table 1. However, ethylene-sensitive climacteric fruits, such as bananas, are more prone to food loss and wastage due to overripe and decayed fruits. Care should be taken not to store ethylene producers with ethylene-sensitive crops.

Physiological Injury

Chilling injury is a common physiological injury that causes economic losses. Several fruits are used before maturation, such as non-climacteric zucchini, which suffer from chilling injury and are associated with a rise in endogenous ethylene. During chilling injury, a burst of reactive oxygen species occurs, and ethylene is produced as a stress response, causing the symptoms associated with chilling injury.

Pathogen Activity

The increase in ripeness and senescence enhances fruit susceptibility to bacteria and fungi.

Due to ethylene’s role in ripening in climacteric fruits, this category is affected and attacked by mold and bacteria, but non-climacteric fruits remain unaffected.

At lower ethylene concentrations (0.1 μL L−1), pathogen growth was delayed. At higher ethylene levels, the reduction in cellular integrity in fruit tissues makes it easier for fungi to colonize the tissue and access its nutrients. Non-climacteric fruits experience no increase in postharvest ethylene and respiration rates, and so fungi do not get any help in colonizing these fruits.

Controlling Ethylene

Several methods are available for limiting ethylene production or removing ethylene from storage rooms, shipping containers, and packages to extend the shelf life of fruits. Monitoring ethylene levels is a vital component to lower ethylene levels in the fruit supply chain. However, most methods involve destructive sampling. Felix Instruments’ Applied Food Science electrochemical gas analyzers can non-destructively measure ethylene precisely and rapidly, within seconds, with a resolution of one part per billion (ppb). The company offers portable versions, such as the F-900 Portable Ethylene Analyzer. The fixed instruments F-901 AccuRipe & AccuStore can be used to constantly monitor ethylene levels, 24/7, and control ethylene levels in storage and shipping facilities.

Contact Felix Instruments Applied Food Science for more details on our ethylene detectors for your facilities.

Sources

Alonso-Salinas, R., López-Miranda, S., Pérez-López, A. J., & Acosta-Motos, J. R. (2024). Strategies to delay ethylene-mediated ripening in climacteric fruits: Implications for shelf life extension and postharvest quality. Horticulturae, 10(8), 840.

Asrey, R., Sharma, S., Barman, K., Prajapati, U., Negi, N., & Meena, N. K. (2023). Biological and postharvest interventions to manage the ethylene in fruit: a review. Sustainable Food Technology, 1(6), 803-826.

Blanke, M. Challenges of Reducing Fresh Produce Waste in Europe—From Farm to Fork. Agriculture, 5(3), 389-399. https://doi.org/10.3390/agriculture5030389

Cocetta, G., and Natalini, A. (2022). Ethylene: Management and breeding for postharvest quality

In vegetable crops. A review. Front. Plant Sci. 13:968315. doi: 10.3389/fpls.2022.968315

Ebrahimi, A., Zabihzadeh Khajavi, M., Ahmadi, S., Mortazavian, A. M., Abdolshahi, A., Rafiee, S., & Farhoodi, M. (2022). Novel strategies to control ethylene in fruit and vegetables for extending their shelf life: A review. International Journal of Environmental Science and Technology, 19(5), 4599-4610.

Keller, N., Ducamp, M. N., Robert, D., & Keller, V. (2013). Ethylene removal and fresh product storage: a challenge at the frontiers of chemistry. Toward an approach by photocatalytic oxidation. Chemical reviews, 113(7), 5029-5070.

Mariah, M. A., Vonnie, J. M., Erna, K. H., Md, N., Huda, N., Abdul Wahab, R., & Rovina, K. The Emergence and Impact of Ethylene Scavengers Techniques in Delaying the Ripening of Fruits and Vegetables. Membranes, 12(2), 117. https://doi.org/10.3390/membranes12020117

Morales, J., Cervera, L., Navarro, P., & Salvador, A. (2023). Quality of Postharvest Degreened Citrus Fruit. IntechOpen. doi: 10.5772/intechopen.105119

Pristijono, P., Wills, R. B., Tesoriero, L., & Golding, J. B. Effect of Continuous Exposure to Low Levels of Ethylene on Mycelial Growth of Postharvest Fruit Fungal Pathogens. Horticulturae, 4(3), 20. https://doi.org/10.3390/horticulturae4030020

Schaller, G. E., & Kieber, J. J. (2002). Ethylene. The Arabidopsis Book / American Society of Plant Biologists, 1, e0071. https://doi.org/10.1199/tab.0071

Wray-French, L. (2013). A review of ethylene management techniques controlling the shelf life of perishables and research into two new types of ethylene scrubbing technologies. Food Safety and Quality Management Masters.

Zhang, J., Cheng, D., Wang, B., Khan, I., & Ni, Y. (2017). Ethylene control technologies in extending postharvest shelf life of climacteric fruit. Journal of Agricultural and Food Chemistry, 65(34), 7308-7319.

Related Products

- F-751 Grape Quality Meter

- Custom Model Building

- F-910 AccuStore

- F-751 Melon Quality Meter

- F-751 Kiwifruit Quality Meter

- F-750 Produce Quality Meter

- F-751 Avocado Quality Meter

- F-751 Mango Quality Meter

- F-900 Portable Ethylene Analyzer

- F-950 Three Gas Analyzer

- F-920 Check It! Gas Analyzer

- F-960 Ripen It! Gas Analyzer

- F-940 Store It! Gas Analyzer

Most Popular Articles

- Spectrophotometry in 2023

- The Importance of Food Quality Testing

- NIR Applications in Agriculture – Everything…

- The 5 Most Important Parameters in Produce Quality Control

- Melon Fruit: Quality, Production & Physiology

- Fruit Respiration Impact on Fruit Quality

- Guide to Fresh Fruit Quality Control

- Liquid Spectrophotometry & Food Industry Applications

- Ethylene (C2H4) – Ripening, Crops & Agriculture

- Active Packaging: What it is and why it’s important