March 2, 2026 at 9:50 pm | Updated March 2, 2026 at 10:06 pm | 11 min read

- Innovations and emerging treatment technologies help preserve the postharvest quality of fresh produce by reducing microbial contamination and slowing ripening and senescence.

- Many innovations maintain and enhance sensory, internal, and nutritional quality and increase shelf life.

- Several innovations and emerging technologies require further research to assess performance, safety, operating parameters, and economic feasibility.

Approximately 50% of fruits and vegetables are lost during the postharvest stages, according to the 2024 Food and Agriculture Organization (FAO) report, due to quality deterioration, spoilage, and reduced shelf life. Fresh produce remains biologically active after harvest and continues respiration, biochemical changes, ripening, and senescence. Moreover, they are also affected by environmental conditions and diseases. Therefore, postharvest preservation is vital. Recent research addresses these needs and the demand for sustainable, environmentally friendly, safe preservation technologies to replace conventional chemical preservation techniques. In this article, seven of the most vital recent discoveries are discussed.

-

UV-C Treatment

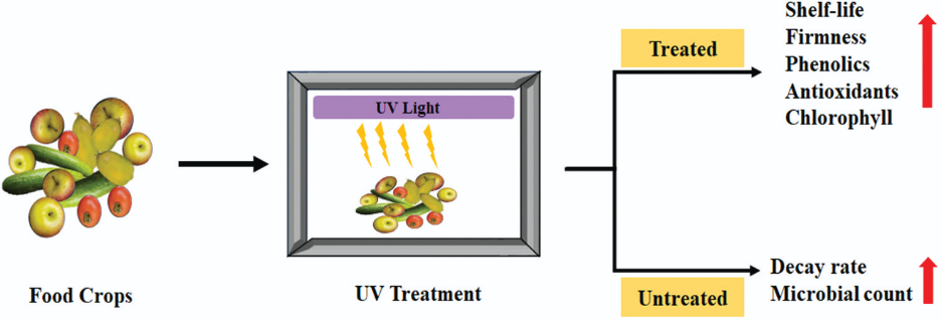

Ultraviolet C (UV-C) radiation in the 200–280 nm wavelength range is well known for its germicidal and microbial inactivation properties. Several studies have highlighted the positive effects of this non-thermal treatment on the postharvest quality of fresh produce by reducing microbial contamination, delaying postharvest senescence, and preserving nutraceuticals (see Figure 1):

- Deactivates microbes: Applying UV-C radiation induces oxidative stress in microbes, leading to their inactivation and less spoilage. For example, applying UV-C radiation immediately after cutting and before packing reduces Enterobacteriaceae counts compared with untreated fruits.

- Preserves biochemicals: It is a viable alternative to thermal methods, which can degrade heat-sensitive biocompounds such as antioxidants, vitamins, and pigments. UV-C modulates the activity of enzymes involved in the degradation of pigments and polysaccharides, thereby preserving the structural integrity of these compounds and keeping chlorophyll and greenness intact. UV-C also increases the accumulation of phenols and antioxidants, thereby preserving food’s nutritional value. For example, UV-C exposure increased carotenoid and flavonoid accumulation by 59% and 36%, respectively, in bell peppers.

- Slows physiology: UV-C delays the respiration peak, reduces ethylene production, and slows firmness loss and senescence, thereby improving the quality of fresh produce, for example, in peaches.

However, excessive use of UV-C has adverse effects on postharvest produce quality, as it can cause oxidative stress, physiological changes, and tissue damage. Too much UV-C can cause surface discoloration, loss of firmness, textural degradation, reduced nutritional compounds, and increased respiration and ethylene production. For example, high-intensity UV-C causes chlorophyll degradation in leafy vegetables. Therefore, research on dosage, exposure time, and light intensity is necessary to determine effectiveness for each species.

Subscribe to the Felix instruments Weekly article series.

By submitting this form, you are consenting to receive marketing emails from: . You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact

Figure 1. “Post-harvest UV treatment of food crops showing improved physiological properties and enhanced storage life as compared to the untreated crops, which have greater microbial counts and higher decay rate,” Lalpekhlua et al. 2024. (Image credits: https://doi.org/10.1080/19315260.2024.2392551)

-

Pulsed Light Treatment

Pulsed light (PL) technology is another non-thermal treatment that uses short, intense pulses in the 200-1100 nm range emitted by xenon lamps. PL treatments improve postharvest disease resistance, increase shelf life, and maintain quality and flavor.

- Impact on quality: PL treatment improves quality by stressing fruit tissue, which stimulates the production of antioxidants and secondary metabolites that help maintain postharvest quality during storage. For example, PL increases the levels of flavonoids and phenols in apricots. PL treatments also preserve quality parameters such as firmness, fruit color, total soluble solids, and reduce weight loss, for example, in tomatoes. It also improves aroma by preventing the degradation of volatile compounds and the formation of off-flavors.

- Prevents microbial spoilage: PL treatment is effective against various microbes, such as aerobic mesophilic bacteria and mold. For example, it reduces fungal decay in strawberries, bacterial infections in tomatoes, and Fusarium lesions in melons.

- Induces disease resistance: PL treatment enhances disease resistance by stimulating defense responses and altering physiology and metabolism, thereby increasing shelf life. Thus, treated fresh produce decays less. For example, PL treatment activates defense in tomato by mediating the production of ethylene, jasmonic acid, and salicylic acid.

Through its many actions, PL treatment can extend the shelf life of fresh produce.

-

Edible Coatings

Edible coatings can extend shelf life by forming a protective barrier against moisture loss, oxidation, and microbial infection. The edible coatings can also reduce softening and deterioration, delay ripening, preserve quality, and extend shelf life. The coatings maintain quality by reducing moisture loss, preserving juiciness, firmness, and texture.

The coatings are made from natural polymers such as chitosan and alginate, are safe for consumption and the environment, and provide an alternative to chemical coatings. The addition of essential oils and bioactive compounds enhances the coatings’ functionality, thereby increasing shelf life. By reducing water loss or fruit transpiration, weight loss is limited

Selecting the correct material for preparing edible coatings is essential to maximize benefits. The materials used will depend on the fruit type, intended applications, functions, and regulatory requirements. Improper material selection can lead to off-flavors, changes in natural flavors, or the introduction of harmful contaminants, making food unsafe. The edible coating materials are also influenced by their sensitivity to environmental conditions, pH, application range, and durability over time.

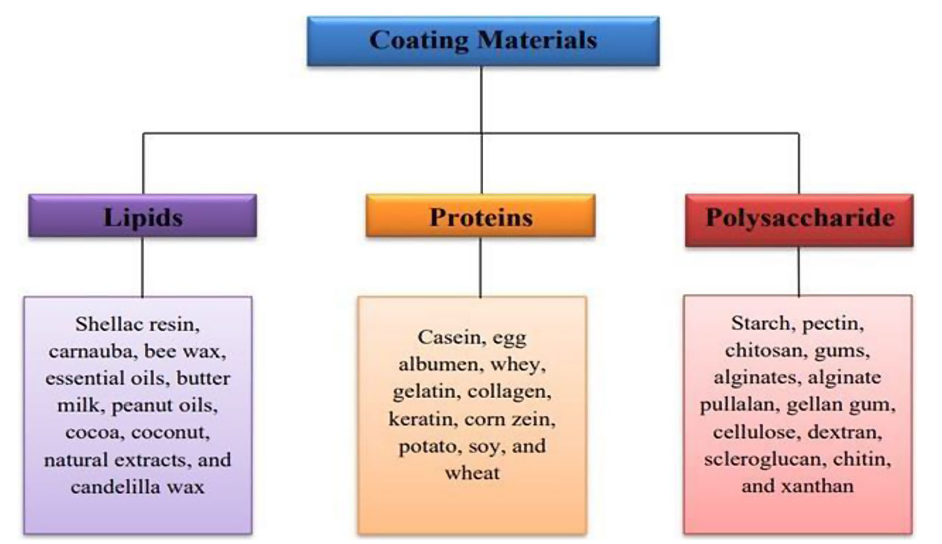

Food coatings are classified into three groups based on their chemical composition: lipids, proteins, and polysaccharides.

Figure 2: “Coating materials used as edible coatings for food preservation,” Gidado et al. (2025). (Image credits: https://doi.org/10.1007/s13197-025-06214-1)

- Polysaccharide-based coatings: Polysaccharides are the most widely used materials for fruit preservation, but they also have limitations. The coatings are sensitive to water and can lose structural integrity in high humidity. They can change appearance, texture, and taste, and are not suitable for certain fruits. These coatings limit gas exchange, affecting respiration and fruit quality. Carbon dioxide produced during fruit respiration accumulates, leading to anaerobic respiration or fermentation. They also have limited water barrier properties, which can lead to dehydration.

- Protein-based coatings: These coatings, commonly used for fruit preservation, have limitations. Their water-loss capacity is lower than that of wax and chemical coatings, which can lead to quality loss due to wilting and shriveling. High concentrations can change the appearance and texture of fruits. Shelf life is shorter, and high temperatures degrade the coatings, reducing their performance.

- Lipid-based coatings: Lipids have been studied for applications, but they have several limitations, including variable permeability and antimicrobial activity, an oily sensation, and potential toxic effects. Therefore, their applications for fresh produce preservation are limited.

The various materials and sources for the three groups of edible coatings are listed in Figure 2. Coatings can be applied to fruits and vegetables by dipping, brushing, or spraying them with the coating solution.

-

Peptides

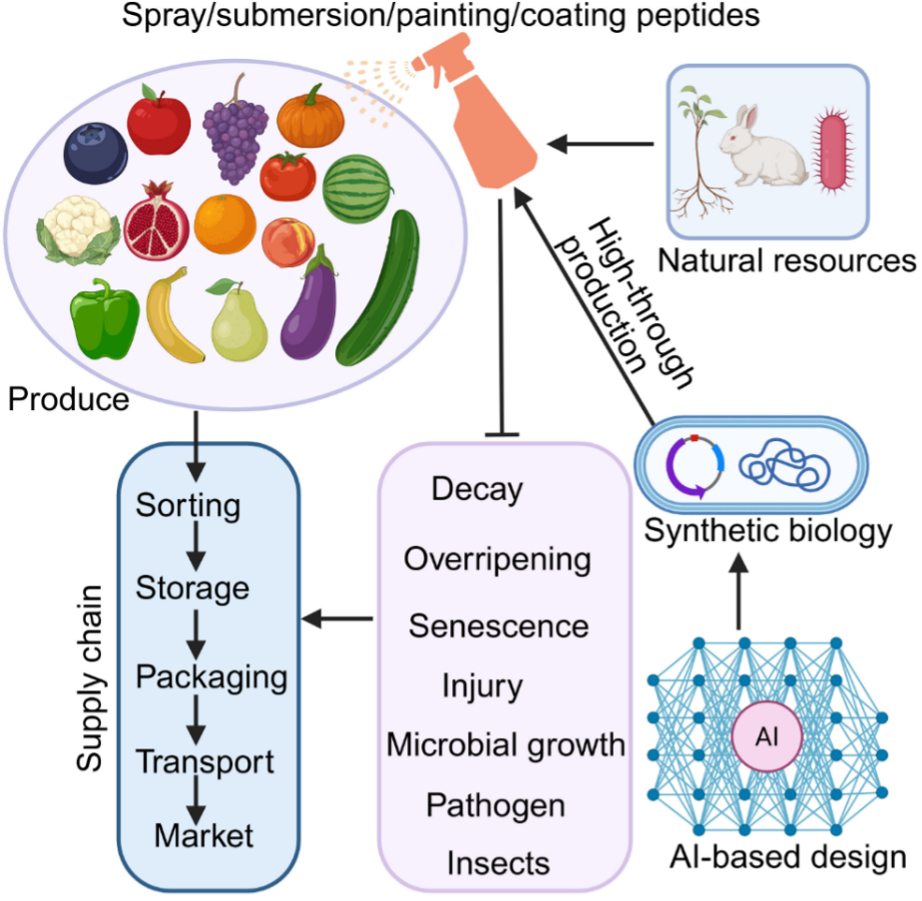

Figure 3: “A simplified model of peptide hormones in the postharvest preservation and quality control of horticultural produce,” Niu et al. (2025). (Image credits: https://doi.org/10.3389/fpls.2025.1700360)

Antimicrobial peptides (AMPs) are among the most promising alternatives for controlling postharvest diseases. Peptides can be sourced naturally or artificially synthesized using AI and synthetic biology. In addition to its antimicrobial properties, it can inhibit overripening, decay, senescence, and physical damage, helping maintain fresh produce quality and shelf life.

Small peptides consist of 2-100 amino acids and are grouped into conventional and non-conventional peptides. Peptides offer several advantages, including structural diversity, abundant sources, membrane permeability, low toxicity, and biodegradability.

- Unconventional peptides: Small peptides currently used in postharvest management and fruit ripening are unconventional peptides that exhibit antimicrobial, antioxidative, and barrier-forming properties. For example, NOP-1, derived from the Arabidopsis ethylene regulator, and can block ethylene signaling and delay ripening processes in tomato. However, unconventional peptides need complex biosynthesis, which hinders their further study and application.

- Conventional peptides: These peptides have well-defined mechanisms and functions and are best suited for horticultural applications. Conventional peptides are involved in signaling and biosynthesis of ethylene. These peptides also induce tolerance to cold stress, senescence, and resistance against pathogens. These properties are interesting in postharvest management.

Though significant advances have been made in peptide research, their commercial applications to extend postharvest longevity are limited by poor stability, inefficient delivery, low bioavailability, and high production costs.

Small peptides can be applied as sprays, paints, coatings, and dips to harvested fresh produce and growing plants, as shown in Figure 3. Peptides can also be combined with nanomaterials, edible composites, and MAP packaging.

-

Ozone

Microbial contamination is one of the main causes of fresh produce deterioration and limited shelf life. Chemical disinfectants, such as chlorine-based products, can form toxic byproducts and pose risks to human health and the environment. Ozone (O3), known for its strong oxidizing capacity, is an emerging, safe, and sustainable disinfection technology. It has the advantage of breaking down to produce harmless oxygen. Ozone applications in fresh produce preservation can work in three areas to improve shelf life:

- Antimicrobial properties: Ozone’s oxidizing capacity deactivates microbes and reduce their incidence.

- Reduces pesticide residues: Ozone can degrade pesticide residues on food.

- Slows the ripening process: Ozone can also slow the ripening process and improve sensory and nutritional compounds to maintain quality and extend shelf life.

Ozone applications can use it as a gas, ozonized water, and ozonized mist. It is essential to consider ozone concentration, exposure time, and product sensitivity to make specific recommendations for individual fresh produce items. Inadequate doses can harm by inducing oxidative stress and damaging organoleptic quality attributes. Widespread application is currently challenging due to knowledge gaps about its use in food science, varying regulations, and commercial acceptance. Combining ozone with other technologies, such as modified atmosphere packaging and cool storage, could be a useful approach for integrating ozone into postharvest management of fresh produce.

-

Nanotechnology

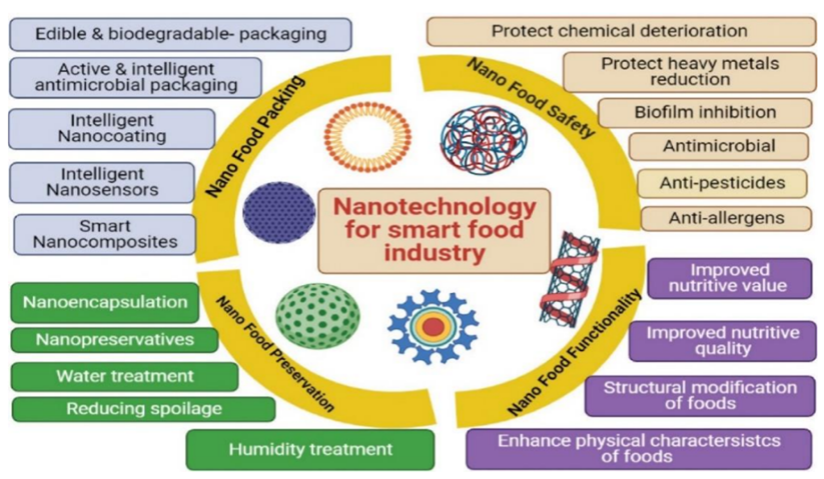

Nanotechnology applications are an emerging field in food science. Nanotechnology involves the manipulation of materials or devices at the nanometer scale (1–100 nm) to develop new materials with unique physicochemical properties such as strength, color, diffusion, and toxicity.

Figure 4: “Nanotechnology applications for improving food packing, preservation safety, and functionality,” Ansari 2023. (Image credits: doi: 10.3390/plants12132565).

Nanomaterials can enhance fresh produce safety, quality, and functionality, with the following applications:

- Nanocoatings or nanocomposites: They protect food by acting as a barrier against moisture loss, gas exchange, microbial contamination, chemicals, and pesticides. Some nano-sorbents regulate ethylene to delay ripening and spoilage. Nanomaterials can improve shelf-life. For example, nanomaterials combined with chitosan coatings can control microbial growth of mold, yeast, and bacteria, thereby moderating weight loss, titrable acidity, and the ripening index. The coating can also increase peroxidase and polyphenol oxidase activities, for example, resulting in an extension of blueberry shelf-life.

- Nanocapsulation: This application is used to release any required compounds. These can be antimicrobial agents that extend the shelf life of fresh produce. Or nano capsules can contain bioactive compounds that improve nutrient bioavailability, protect against heat and moisture, enhance thermal and photostability, and extend shelf life.

- Nanosensors: The tiny sensors can be integrated into packaging materials to enable real-time monitoring of product freshness and quality, temperature, and humidity, helping detect and prevent food spoilage. Stakeholders can use the sensor data to adjust handling and shelf life.

- Nano-bubbles: Tiny nano-bubbles formed with air, ozone, carbon dioxide (CO2), and 1-MCP can be used for fumigation and soaking, as the new technology increases gas solubility and retention in water. It can be used as a cleaning method that avoids chemicals and is therefore environmentally friendly. Nanobubbles can also be used to kill microbes and reduce ethylene production. Nanobubble use is mature in other sectors but remains experimental in postharvest food management.

Though nanotechnology is promising (see Figure 4), none of the nanomaterial-based packaging meets the requirements of postharvest storage and transport. The safety assessment of nanomaterials is also incomplete. The acute and chronic effects, and possible molecule migration into fresh produce during storage, are critical areas where knowledge is lacking. Currently, the US Environmental Protection Agency considers nanomaterials a risk for human health and the environment.

-

Cold Plasma

Figure 5: Representation of different applications and advantages of plasma treatment of various food crops, including nuts, fruits, vegetables, grains, root vegetables, spices, and herbs in the food industry, Lalpekhlua et al. 2024. (Image credits: DOI:10.1080/19315260.2024.2392551)

Cold plasma, especially atmospheric-pressure cold plasma (APCP), is an emerging non-thermal technology for surface decontamination and the preservation of cut and whole fresh produce, enhancing food safety, quality, and shelf life (see Figure 5):

- Decontamination: APCP can degrade mycotoxins and pesticide residues. Cold plasma can sterilize the surfaces of fresh produce without affecting their sensory and nutritional quality.

- Antimicrobial: Cold plasma deactivates foodborne pathogens and spoilage microbes, reducing their numbers. It also specifically targets microbes without affecting the color, taste, or texture of fresh produce.

APCP has fast processing times and involves little heat transfer to food products. It is chemical-free and safe. It has a wide range of potential applications for fresh produce, meat, and packaged food. APCP can be combined with packaging films to increase their strength and antimicrobial properties.

However, there are gaps in our knowledge of cold plasma. The effect of key operational parameters (flow rate, carrier gas, power input, voltage, and frequency) is unknown. Moreover, these parameters must be optimized for each food type. Short-term effects are well researched. However, being an emerging technology, long-term effects on food structural integrity, nutritional and quality alteration, etc., remain unstudied. The economic feasibility and scalability must also be ascertained.

Optimizing Emerging Technologies

Innovations and emerging treatments could potentially preserve fresh produce, reduce food loss, and improve food security and the economic viability of supply chains. While several exciting, sustainable, and safe technologies are emerging as alternatives to conventional chemicals, they are not ready for the market. Even new technologies on the market need more studies for wider applications. Researchers will benefit from using precision technology to measure quality parameters in real time and evaluate the effects and benefits of new technology for fresh produce. Similarly, stakeholders in the fresh produce supply chain will need precision tools to measure quality and optimize daily applications of technology. Felix Instruments Applied Food Science offers several near-infrared spectroscopy-based quality meters for measuring and analyzing parameters such as internal and external color, dry matter content, soluble sugar content, and titratable acidity.

Contact us to find out more about Felix Quality Meters for your research and industry needs.

Sources

Ansari, M.A. 2023. Nanotechnology in food and plant science: Challenges and future

prospects. Plants 12(13):2565. doi: 10.3390/plants12132565.

Ashraf, M. A., Khan, A. S., Azam, M., Ayyub, S., Kaleem, M. M., Nawaz, S., … & Ateeq, M. (2025). Innovative technologies in postharvest management of fruits and vegetables: a review. European Food Research and Technology, 251(11), 3445-3463.

Gidado, M. J., Gunny, A. A. N., Gopinath, S. C., Devi, M., Jayavalli, R., & Ilyas, R. A. (2025). Challenges in selecting edible coating materials for fruit postharvest preservation and recent advances in edible coating techniques: a review. Journal of Food Science and Technology, 1-11.

Keewan, M., Krishnamoorthy, R., Show, P. L., Tang, D. Y. Y., & Banat, F. (2025). Atmospheric‐Pressure Cold Plasma: A Next‐Generation Nonthermal Technology for Enhancing Food Safety, Quality, and Shelf Life. Food Frontiers, 6(6), 2766-2788.

O’Brien, C., & Alamar, M. C. (2025). An overview of non-destructive technologies for postharvest quality assessment in horticultural crops. The Journal of Horticultural Science and Biotechnology, 1-9.

Lalpekhlua, K., Tirkey, A., Saranya, S., & Babu, P. J. (2024). Post-harvest Management

Strategies for Quality Preservation in Crops. International Journal of Vegetable Science, 30(5), 587-635.

Niu, J., Bao, H., Jiao, S., Han, H., and Wang, G. (2025) Harnessing peptide hormones for postharvest preservation of horticultural produce. Front. Plant Sci. 16:1700360.

doi: 10.3389/fpls.2025.1700360

Verma, S., Kumar, S., Kumar, V., Yadav, S., Singh, P., Saurabh, A., … & Jain, M. (2025). Recent Advancements and Innovations in Post-harvest Handling, Storage, and Technology for Vegetables: A Review. Archives of Current Research International, 25(2), 161-180. https://doi.org/10.9734/acri/2025/v25i21076

Ramesh, B. N., Niveditha, P. A., Nagesha, S. N., Charith, R., & Hithashree, D. M. (2025). Antimicrobial peptides in post-harvest management of fruits. Journal of Food Science and Technology, 1-12.

Rojas, M. F., Houmy, K., & Fawole, O., eds. (2024). Post-harvest management: bridging gaps and embracing innovations. Rome, FAO. https://doi.org/10.4060/cd1185en

Shan, Y., Li, T., Qu, H., Duan, X., Farag, M. A., Xiao, J., … & Jiang, Y. (2023). Nano‐preservation: An emerging postharvest technology for quality maintenance and shelf life extension of fresh fruit and vegetable. Food Frontiers, 4(1), 100-130.

Sitoe, E. D. P. E., Faroni, L. R. D. A., Lima, C. M. G., Leite, N. N., Morais, R. A., Pacheco, F. C., … & Rocha, R. A. D. (2025). Exploiting ozone for post-harvest preservation of fruits and vegetables: Application techniques, quality effects, and regulatory frameworks. Food Reviews International, 1-32.

Tao, J., Zuo, J., Wang, Y., Fernie, A. R., Bai, C., Liu, S., … & Zheng, Y. (2025). The effect of pulsed light treatment on the postharvest resistance and flavor quality of fresh tomato. Horticultural Plant Journal.

Toyen, D., Suppakul, P., Siwayaprahm, P., Thanomchat, P., Sukatta, U., Kosawatpat, P., … & Saenboonruang, K. (2025). Optimizing UV-C treatment for postharvest quality preservation of sea grapes (Caulerpa lentillifera). Postharvest Biology and Technology, 227, 113602.

Zaman, W., Amin, A., Khalil, A. A. K., Akhtar, M. S., & Ali, S. (2025). Plant–Microbe Interactions for Improving Postharvest Shelf Life and Quality of Fresh Produce through Protective Mechanisms. Horticulturae, 11(7), 732. https://doi.org/10.3390/horticulturae11070732

Related Products

Most Popular Articles

- Spectrophotometry in 2023

- The Importance of Food Quality Testing

- NIR Applications in Agriculture – Everything…

- The 5 Most Important Parameters in Produce Quality Control

- Melon Fruit: Quality, Production & Physiology

- Fruit Respiration Impact on Fruit Quality

- Guide to Fresh Fruit Quality Control

- Liquid Spectrophotometry & Food Industry Applications

- Ethylene (C2H4) – Ripening, Crops & Agriculture

- Active Packaging: What it is and why it’s important