November 16, 2017 at 12:09 am | Updated November 16, 2017 at 12:09 am | < 1 min read

If you work in postharvest, chances are you’re familiar with ethylene—C2H4—a gas produced by aging fresh produce, rotting vegetation, and different byproducts like smoke and exhaust.

Why is ethylene on the postharvest professional’s radar? Our infographic below explains.

Ethylene can be a blessing or a curse. QA managers use scrubbers and ventilation systems in controlled storage to remove ethylene, slowing down ripening and preventing spoilage in fresh produce during storage and transit. Ethylene can be damaging, but it is also an important postharvest tool. Ripening room personnel apply ethylene using tools like catalytic generators in air tight rooms to initiate the ripening process in climacteric fruits—those that can be picked when they reach physiological maturity and then ripened off of the plant. Citrus professionals use ethylene to remove chlorophyll and enhance coloration.

Subscribe to the Felix instruments Weekly article series.

By submitting this form, you are consenting to receive marketing emails from: . You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact

Ethylene is a big deal for the postharvest industry, yet often the tools and techniques employed for removing or applying ethylene are imprecise or faulty, the result of which can be spoiled produce or wasted ethylene gas.

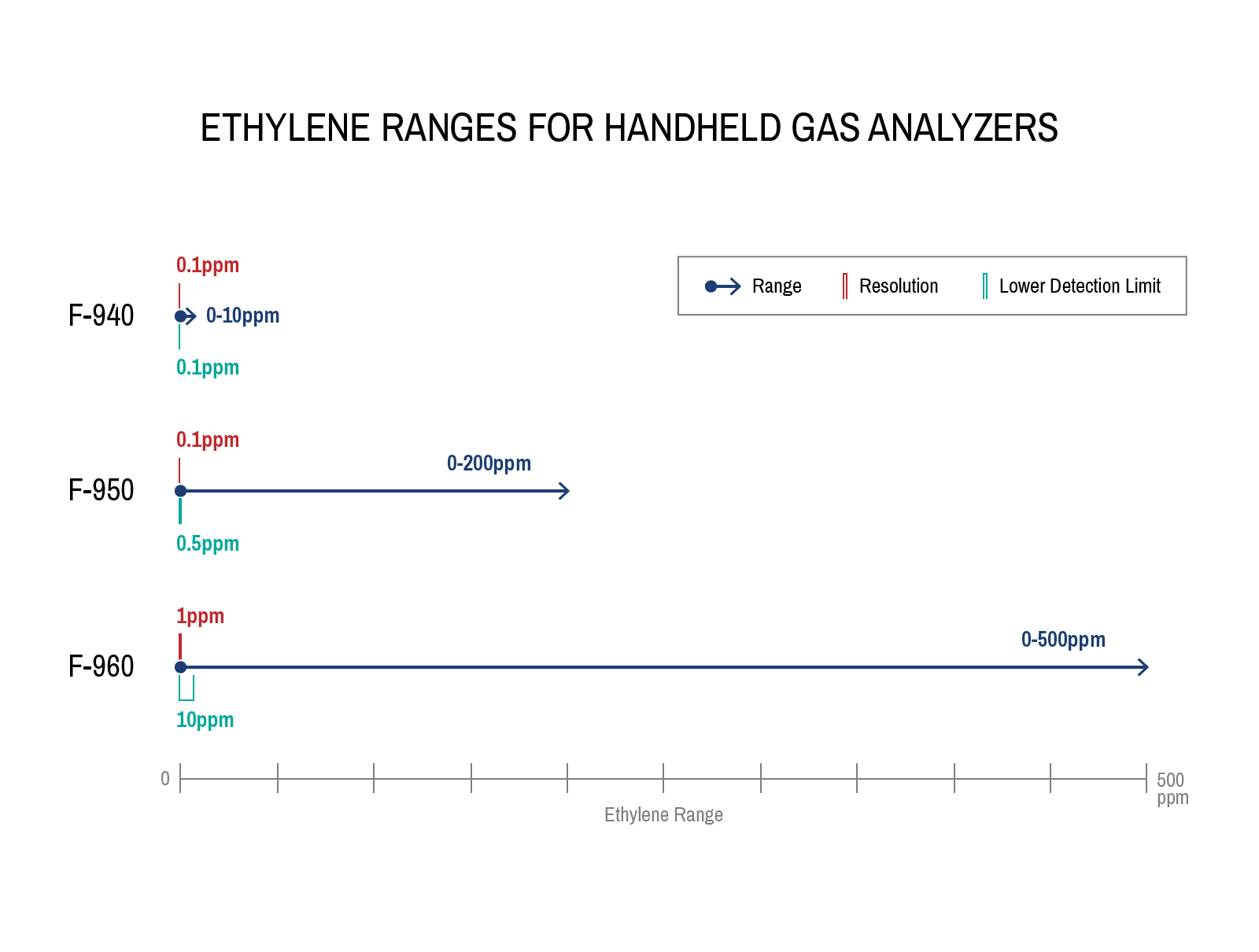

Luckily, we designed a line of easy to use, handheld ethylene analyzers to help professionals make precise measurements of ethylene in a variety of ranges and environments, and to best manage their phase of the cold chain. See our full line of gas analyzers here.

Related Products

- Felix Expansion Card

- F-751 Grape Quality Meter

- Custom Model Building

- F-910 AccuStore

- F-751 Melon Quality Meter

- F-751 Kiwifruit Quality Meter

- F-750 Produce Quality Meter

- F-751 Avocado Quality Meter

- F-751 Mango Quality Meter

- F-900 Portable Ethylene Analyzer

- F-950 Three Gas Analyzer

- F-920 Check It! Gas Analyzer

- F-960 Ripen It! Gas Analyzer

- F-940 Store It! Gas Analyzer

Most Popular Articles

- Spectrophotometry in 2023

- The Importance of Food Quality Testing

- NIR Applications in Agriculture – Everything…

- The 5 Most Important Parameters in Produce Quality Control

- Melon Fruit: Quality, Production & Physiology

- Fruit Respiration Impact on Fruit Quality

- Guide to Fresh Fruit Quality Control

- Liquid Spectrophotometry & Food Industry Applications

- Ethylene (C2H4) – Ripening, Crops & Agriculture

- Active Packaging: What it is and why it’s important