February 5, 2026 at 9:35 pm | Updated February 5, 2026 at 10:53 pm | 5 min read

Ethylene monitoring systems sit at the center of modern postharvest handling. If you work with fruit, you already know ethylene is both a tool and a problem. It drives ripening, shortens shelf life, and amplifies losses when it is not controlled. The real question is not whether ethylene monitoring systems matter, but what level of system is actually worth paying for.

With so many options on the market, from basic sensors to advanced multi-gas analyzers, the value comes down to accuracy, usability, and how well the system fits real workflows.

This article breaks down what matters when evaluating ethylene monitoring systems and where investment makes sense, especially for operations that care about data they can trust.

Subscribe to the Felix instruments Weekly article series.

By submitting this form, you are consenting to receive marketing emails from: . You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact

Why Ethylene Monitoring Systems Matter in Practice

Ethylene is measured in parts per million or even parts per billion. At those levels, small errors matter. In cold rooms, shipping containers, ripening rooms, and research trials, inaccurate ethylene readings lead to incorrect decisions. Fruit may be released too early, held too long, or treated unnecessarily.

Reliable ethylene monitoring systems allow operators to:

-

Track ripening progress in real time

-

Compare lots and storage conditions

-

Optimize ventilation and scrubbing strategies

-

Document compliance and quality metrics

The cost of a poor decision often outweighs the cost of a better instrument.

The Real Cost Drivers Behind Ethylene Monitoring Systems

Not all ethylene monitoring systems are built the same. Price differences usually reflect design choices that directly impact data quality and ease of use.

Sensor Technology

Electrochemical sensors are common at the low end. They can work, but they often drift, require frequent calibration, and struggle at very low concentrations. Optical and laser-based technologies are more stable and sensitive, which matters when monitoring climacteric fruit at early stages.

Paying more for better sensor technology usually means:

-

Lower detection limits

-

Reduced calibration frequency

-

Better long-term consistency

For commercial operations, this reliability often translates into fewer surprises.

Sampling Method

Some ethylene monitoring systems rely on ambient air sampling, while others actively draw samples from headspace, packaging, or chambers. Active sampling gives more control and repeatability, especially when testing bins, boxes, or sealed environments.

Handheld analyzers with pumps allow spot checks exactly where ethylene is generated. That flexibility is often undervalued until problems arise.

Single-Gas vs Multi-Gas Capability

Ethylene rarely acts alone. Oxygen and carbon dioxide levels influence respiration and ripening behavior. Systems that measure only ethylene give part of the picture.

Multi-gas ethylene monitoring systems allow users to:

-

Understand atmosphere balance

-

Adjust controlled atmosphere settings more precisely

-

Diagnose storage issues faster

If you manage CA storage or ripening rooms, this capability quickly pays for itself.

Portability Versus Fixed Ethylene Monitoring Systems

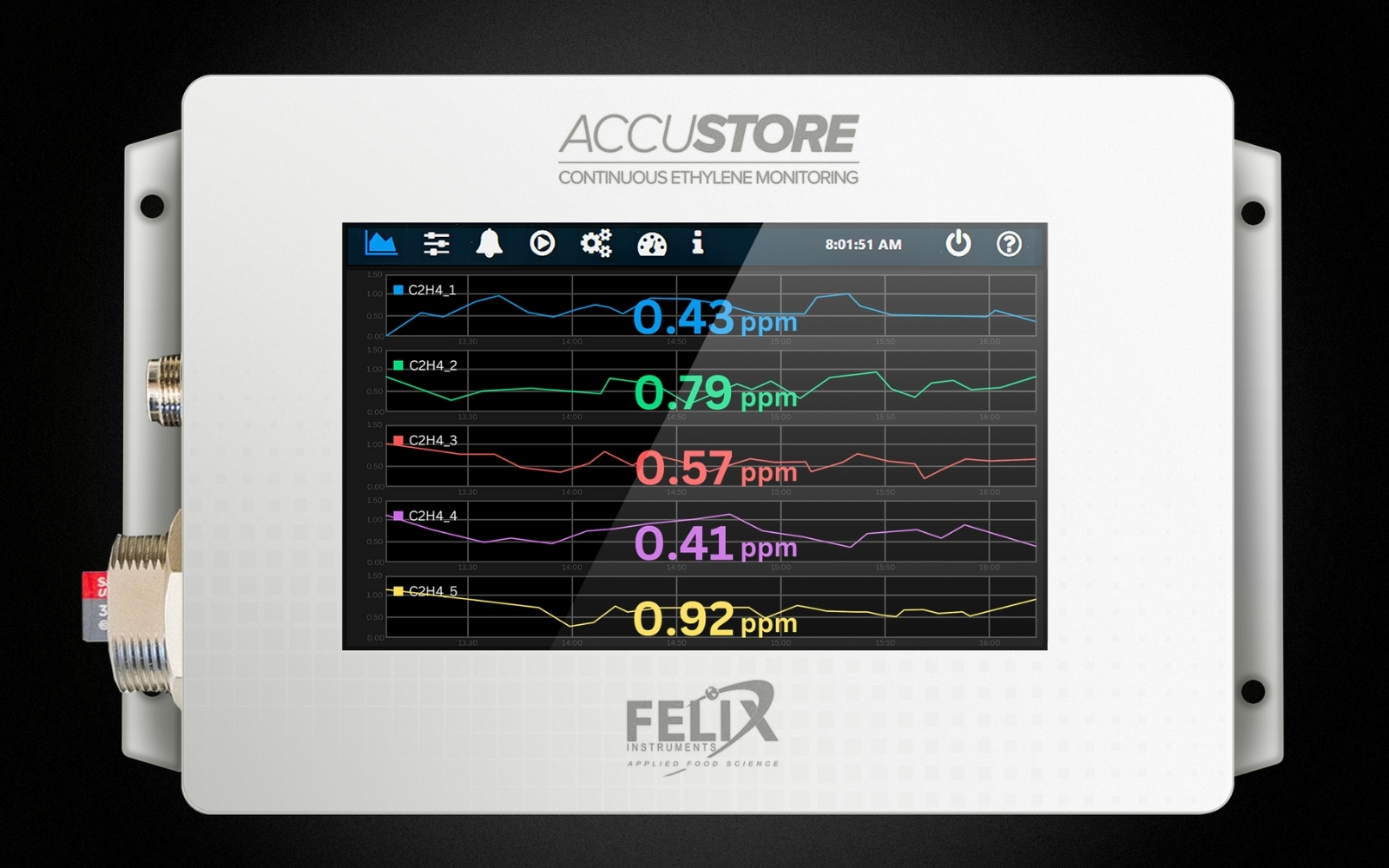

Fixed ethylene monitoring systems are useful for continuous logging in specific rooms. However, they are limited to one location. Portable systems offer flexibility across facilities, rooms, and even field trials.

Portable ethylene monitoring systems are often worth paying for when:

-

Multiple rooms or sites need testing

-

Research trials require mobility

-

Quality teams need verification data

Modern handheld analyzers now match or exceed the performance of older fixed systems, without locking you into a single location.

Data Handling and Usability

An ethylene monitoring system is only as good as the data you can extract from it. Older systems often rely on manual logging, which introduces errors and delays.

Higher-end systems focus on:

-

Clear digital displays

-

Internal data logging

-

USB or wireless data export

-

Simple calibration workflows

These features reduce training time and ensure data can actually be used by quality teams, researchers, and managers.

Where Felix Instruments Fits Into Ethylene Monitoring Systems

Felix Instruments has built its reputation around practical, field-ready ethylene monitoring systems designed for postharvest professionals. Rather than offering generic sensors, Felix focuses on purpose-built analyzers that align with real storage and ripening workflows.

Their handheld ethylene analyzers are widely used because they combine:

-

High sensitivity at low ethylene concentrations

-

Active sampling for consistent measurements

-

Rugged design for packhouses and cold rooms

-

Straightforward operation without excessive setup

Systems like the F-900 series emphasize portability and accuracy, making them suitable for spot checks, audits, and research. Multi-gas options extend that value by pairing ethylene measurements with oxygen and carbon dioxide, giving a fuller view of fruit physiology.

Felix Instruments also integrates ethylene monitoring with complementary tools like non-destructive quality meters, allowing teams to link gas data directly with firmness, dry matter, or maturity metrics.

When Paying More Actually Saves Money

It is tempting to choose the cheapest ethylene monitoring system that claims acceptable accuracy. In practice, low-cost systems often lead to hidden costs.

These include:

-

Frequent recalibration

-

Sensor replacement

-

Questionable data reliability

-

Lost product from delayed or incorrect decisions

Higher-quality ethylene monitoring systems reduce these risks. For high-value crops like apples, avocados, mangoes, and kiwifruit, even small improvements in storage control can prevent significant losses.

If ethylene data influences release timing, treatment decisions, or customer specifications, accuracy is not optional.

Matching Ethylene Monitoring Systems to Your Operation

The best ethylene monitoring system is not always the most expensive one. It is the one that fits how you actually work.

Consider these questions:

-

Do you need spot checks or continuous monitoring

-

Are you managing multiple rooms or sites

-

Do you require multi-gas data

-

Will the system be used by trained technicians or general staff

Portable, user-friendly systems often outperform complex fixed setups in real-world use. Flexibility and reliability tend to matter more than theoretical specs.

The Bottom Line on Value

Ethylene monitoring systems are long-term tools. They shape decisions across seasons, crops, and markets. Paying for proven sensor technology, practical design, and reliable data handling usually delivers a return far beyond the initial cost.

In postharvest environments where margins depend on consistency, the cheapest option is rarely the best one.

Final Thoughts

Ethylene monitoring systems are worth paying for when they deliver data you can trust and workflows that make sense. Accuracy, portability, and multi-gas insight separate professional-grade systems from basic sensors. For operations serious about fruit quality and shelf life, these factors matter every day.

If you are evaluating ethylene monitoring systems or looking to upgrade existing tools, Felix Instruments offers a range of proven solutions designed specifically for postharvest and food science applications. Explore our analyzers, talk with our technical team, and choose a system that supports better decisions from harvest through storage and distribution.

Frequently Asked Questions

What Accuracy Level Should Ethylene Monitoring Systems Provide?

For postharvest fruit applications, systems should reliably detect ethylene at low ppm or ppb levels. Sensitivity at early ripening stages is especially important.

Are Portable Ethylene Monitoring Systems as Reliable as Fixed Systems?

Modern portable analyzers can match or exceed the accuracy of many fixed systems, with the added benefit of flexibility across rooms and facilities.

Is Multi-Gas Measurement Necessary in Ethylene Monitoring Systems?

If you manage controlled atmosphere storage or ripening rooms, measuring oxygen and carbon dioxide alongside ethylene provides a more complete picture and supports better control decisions.

Related Products

Most Popular Articles

- Spectrophotometry in 2023

- The Importance of Food Quality Testing

- NIR Applications in Agriculture – Everything…

- The 5 Most Important Parameters in Produce Quality Control

- Melon Fruit: Quality, Production & Physiology

- Fruit Respiration Impact on Fruit Quality

- Guide to Fresh Fruit Quality Control

- Liquid Spectrophotometry & Food Industry Applications

- Ethylene (C2H4) – Ripening, Crops & Agriculture

- Active Packaging: What it is and why it’s important