February 5, 2026 at 10:06 pm | Updated February 5, 2026 at 10:06 pm | 5 min read

Real-time data logging is no longer a nice-to-have feature in gas monitoring systems. For operations that manage fresh produce, controlled atmosphere storage, ripening rooms, or research trials, it is now a baseline requirement. Accurate gas measurements matter, but how those measurements are captured, stored, and used over time is what ultimately drives better decisions. This buyer’s guide walks through what to look for when evaluating real-time data logging for gas monitoring systems, with a practical focus on how these tools are used in real facilities.

Why Real-Time Data Logging Matters in Gas Monitoring

Real-time data logging allows gas measurements to be recorded continuously rather than captured as isolated snapshots. For gases like ethylene, oxygen, and carbon dioxide, conditions can change quickly. Without continuous records, it is easy to miss short-term spikes, gradual drifts, or equipment issues that affect quality outcomes.

In produce storage and ripening, real-time data logging supports tighter process control. Managers can correlate gas trends with fruit behavior, storage conditions, and final quality results.

Subscribe to the Felix instruments Weekly article series.

By submitting this form, you are consenting to receive marketing emails from: . You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact

In research settings, logged datasets provide defensible records that can be analyzed, shared, and repeated. In both cases, the value comes from having reliable data that reflects what actually happened, not just what was measured during spot checks.

Core Components of a Real-Time Data Logging System

When comparing gas monitoring systems, it helps to break real-time data logging into a few core components.

First is sensor accuracy and stability. Logging poor data more frequently does not improve outcomes. Sensors must maintain accuracy over time, especially in environments with temperature swings and high humidity.

Second is sampling frequency. A system should allow measurements at intervals that match the application. Ripening rooms may require frequent sampling to catch ethylene changes, while long-term storage might focus on slower trends.

Third is onboard memory and data retention. Systems should store enough data to avoid gaps if downloads are delayed. This is particularly important in cold storage facilities where instruments may not be checked daily.

Fourth is data accessibility. Logged data needs to be easy to retrieve and interpret. Whether data is transferred via USB, Bluetooth, or other methods, the process should fit into existing workflows without adding friction.

Gas Types and Why Multi-Gas Logging Matters

Most real-world applications involve more than one gas. Ethylene often gets the most attention, but oxygen and carbon dioxide are just as important in controlled and modified atmospheres.

Real-time data logging becomes more valuable when multiple gases are logged simultaneously. Seeing how ethylene levels change alongside oxygen depletion or carbon dioxide buildup provides a clearer picture of respiration and ripening dynamics. This context helps teams distinguish between normal biological changes and system issues such as leaks or ventilation problems.

When evaluating systems, buyers should confirm that logging covers all relevant gases and that timestamps are synchronized across measurements. Disconnected datasets reduce the usefulness of logged information.

Portability Versus Fixed Monitoring Systems

Another key consideration is whether real-time data logging will be done with portable instruments or fixed installations.

Portable gas analyzers with data logging are common in produce operations. They allow users to move between rooms, containers, or trailers while maintaining consistent measurement and logging capabilities. This flexibility is especially useful during harvest, shipping, and early storage phases.

Fixed systems can offer continuous monitoring in a single location but often require more infrastructure and installation effort. They may also limit flexibility when storage configurations change.

For many buyers, portable systems with robust real-time data logging strike the right balance. They provide high-quality data without locking the operation into a rigid monitoring layout.

Data Integrity and Traceability

Real-time data logging is only useful if the data can be trusted. Buyers should look for systems that protect data integrity through clear timestamps, stable internal clocks, and consistent calibration routines.

Traceability is especially important for operations that supply retailers or exporters with strict quality requirements. Logged data can serve as documentation that storage and ripening conditions stayed within defined limits. In research and breeding programs, traceable datasets support peer review and long-term studies.

Systems that combine gas measurements with metadata such as sample location, room ID, or treatment notes make logged data far more actionable.

Ease of Use in Real Working Environments

Many gas monitoring systems look good on paper but struggle in real facilities. Real-time data logging should not require constant attention or complex setup.

Key usability factors include simple menus, clear status indicators, and minimal steps to start logging. Instruments should handle power interruptions gracefully and resume logging without data loss. Battery life also matters. Logging over long periods should not require frequent charging or battery swaps.

In busy operations, ease of use directly affects whether data logging is done consistently or skipped under pressure.

Software and Post-Collection Analysis

Logging data is only the first step. Buyers should consider how logged data is reviewed and analyzed.

Good systems support straightforward data export into common formats for spreadsheets or statistical software. This flexibility allows teams to apply their own analysis methods without being locked into proprietary platforms.

Some users prioritize simple trend visualization, while others need detailed datasets for modeling and research. The best real-time data logging systems accommodate both without forcing unnecessary complexity.

Comparing Systems on Long-Term Value

Price is always part of the decision, but real-time data logging should be evaluated on long-term value rather than upfront cost alone.

Systems that produce reliable, repeatable data reduce waste, improve quality consistency, and support better operational decisions. Over time, these benefits often outweigh initial savings from lower-cost instruments with limited logging capabilities.

Support and documentation also matter. Clear manuals, responsive technical support, and regular firmware updates contribute to the long-term usefulness of a data logging system.

Why Felix Instruments Stands Out

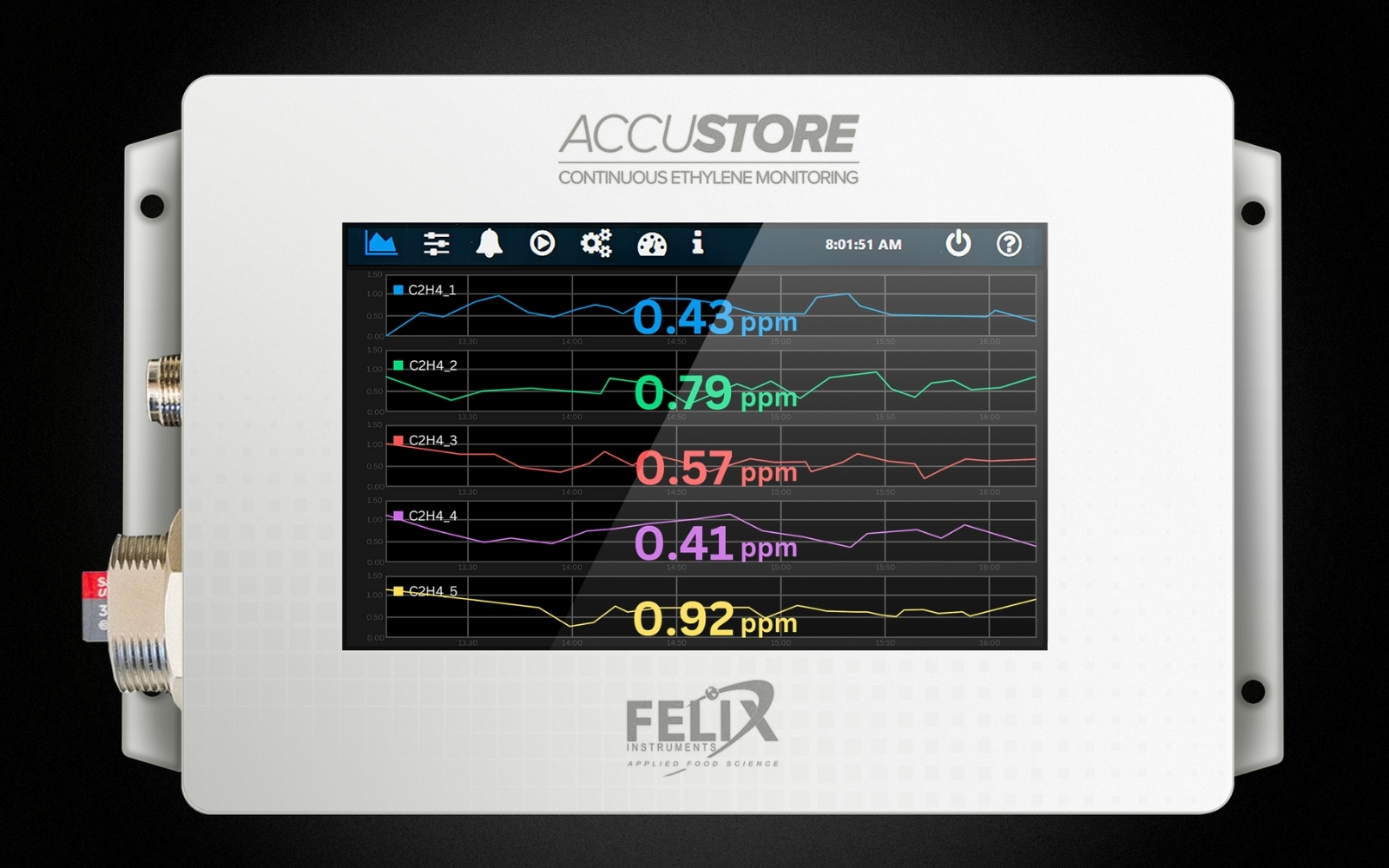

Many buyers turn to Felix Instruments because our gas analyzers are designed around real-world produce and research applications. Across our product line, real-time data logging is treated as a core function rather than an add-on.

Felix systems are built to log ethylene, oxygen, and carbon dioxide with high resolution and stable sensors. Our portable designs support flexible workflows while maintaining consistent data quality. Data retrieval is straightforward, and instruments are engineered to perform reliably in cold storage, ripening rooms, and field environments.

For teams that depend on trustworthy data, this focus on practical logging makes a meaningful difference.

Summary

Choosing the right real-time data logging solution for gas monitoring systems requires looking beyond sensor specs. Buyers should evaluate how data is captured, stored, accessed, and used over time. Multi-gas capability, data integrity, ease of use, and long-term support all play a role in determining value.

If your operation relies on accurate gas measurements to protect quality and improve outcomes, it is worth investing in systems designed with real-time data logging at their core. Explore the full range of solutions from Felix Instruments to see how our approach to data logging can support your monitoring needs today and as your operation grows.

Frequently Asked Questions

What Sampling Interval Is Best for Real-Time Data Logging in Produce Storage?

The ideal interval depends on the application. Ripening rooms often benefit from frequent sampling, while long-term storage may focus on slower trends. The key is flexibility to adjust intervals as conditions change.

Can Portable Gas Analyzers Provide Reliable Real-Time Data Logging?

Yes, when designed properly. Portable analyzers with stable sensors and sufficient memory can deliver high-quality logged data while offering greater flexibility than fixed systems.

How Is Logged Gas Data Typically Used After Collection?

Most users export logged data for trend analysis, quality correlation, and documentation. This data supports decision-making, reporting, and process optimization across storage and ripening operations.

Related Products

Most Popular Articles

- Spectrophotometry in 2023

- The Importance of Food Quality Testing

- NIR Applications in Agriculture – Everything…

- The 5 Most Important Parameters in Produce Quality Control

- Melon Fruit: Quality, Production & Physiology

- Fruit Respiration Impact on Fruit Quality

- Guide to Fresh Fruit Quality Control

- Liquid Spectrophotometry & Food Industry Applications

- Ethylene (C2H4) – Ripening, Crops & Agriculture

- Active Packaging: What it is and why it’s important