February 5, 2026 at 11:08 pm | Updated February 5, 2026 at 11:08 pm | 5 min read

Selecting the right gas analysis tool often comes down to understanding how much information you really need and how you plan to use it. The debate around multi-gas vs single-gas instruments is common in postharvest handling, storage management, and produce research.

Both approaches solve real problems, but they do so in different ways. This article breaks down the practical differences so you can decide which option fits your operation, your workflow, and your data requirements.

What Single-Gas Instruments Do Well

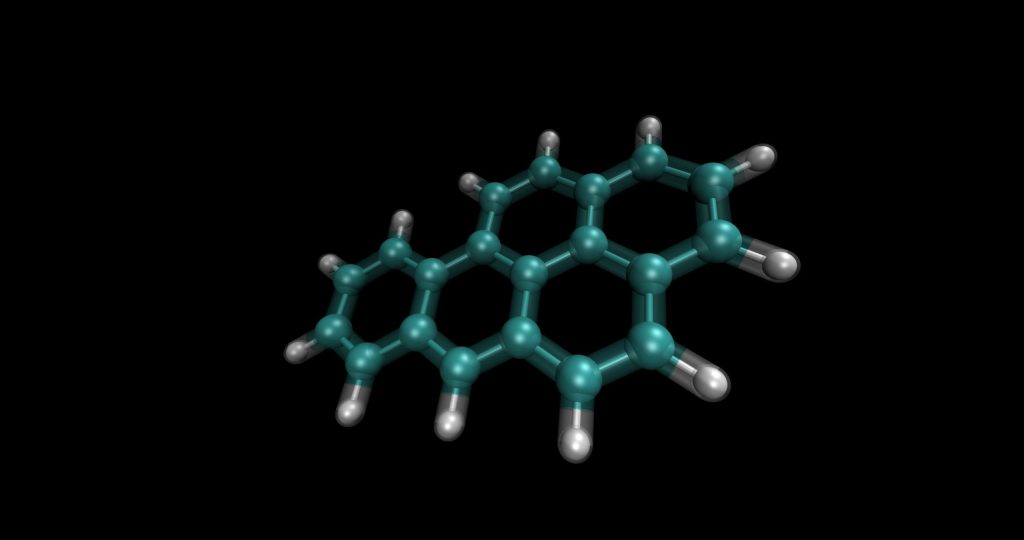

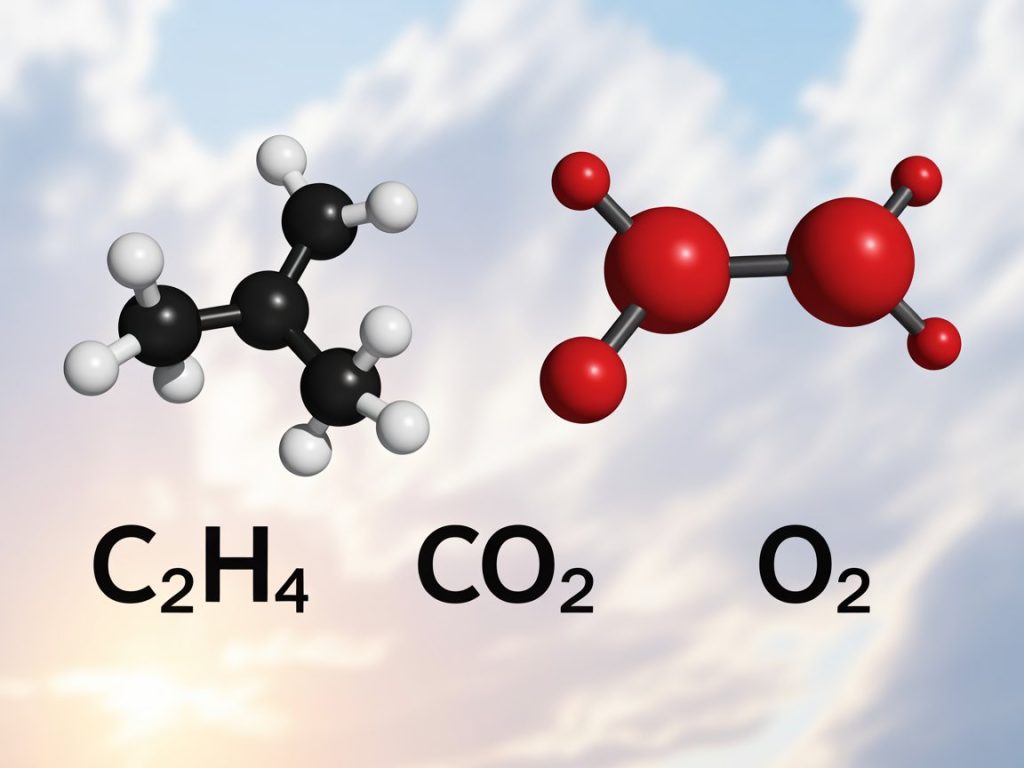

Single-gas instruments are designed to measure one target gas with precision and speed. In produce applications, that gas is often ethylene. Ethylene plays a central role in ripening, senescence, and quality loss, so being able to track it accurately is essential.

Subscribe to the Felix instruments Weekly article series.

By submitting this form, you are consenting to receive marketing emails from: . You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact

Key strengths of single-gas tools

Single-gas instruments are valued for their simplicity. They are easy to learn, fast to deploy, and often require minimal setup. For teams that monitor ethylene at specific checkpoints, such as inbound fruit inspections or ripening room verification, this focused approach is often enough.

Typical advantages include:

-

Direct measurements without extra configuration

-

Short warm-up and sampling times

-

Lower upfront cost compared to multi-gas platforms

-

Clear data that is easy to interpret and report

A portable ethylene analyzer is especially useful when ethylene is the main variable influencing decisions. If your storage conditions are well controlled and oxygen and carbon dioxide levels are already regulated by fixed systems, a single-gas tool can fit neatly into existing workflows.

Common use cases

Single-gas instruments are widely used in:

-

Ripening room audits

-

Cold storage spot checks

-

Incoming fruit quality assessments

-

Research trials focused on ethylene response

In these scenarios, adding more gas data may not significantly change decisions, which makes a dedicated ethylene analyzer a practical choice.

Where Multi-Gas Instruments Add Value

Multi-gas instruments measure two or more gases simultaneously, most commonly ethylene, carbon dioxide, and oxygen. This broader view is valuable when gas interactions matter as much as individual concentrations.

When evaluating multi-gas vs single-gas instruments, this is often the turning point. Multi-gas data reveals patterns that single-gas readings cannot.

Understanding the full atmosphere

Produce quality is influenced by the balance between gases, not just one of them. Ethylene may trigger ripening, but oxygen availability and carbon dioxide buildup can slow or accelerate metabolic processes.

Multi-gas analyzers help users:

-

Diagnose atmosphere issues in storage rooms

-

Validate controlled atmosphere or modified atmosphere systems

-

Understand why fruit behavior differs between lots

-

Correlate gas composition with firmness, sugars, and shelf life

This becomes especially important when storage conditions vary, fruit maturity differs, or multiple commodities are handled in the same facility.

Operational advantages

Although multi-gas instruments are more complex, modern handheld designs keep them portable and user friendly. Having multiple measurements in a single sampling step reduces time spent moving between tools or interpreting separate datasets.

Benefits include:

-

One device instead of multiple sensors

-

Consistent sampling methodology

-

Better context for decision-making

-

Stronger documentation for audits and research

For teams responsible for storage optimization, these advantages often outweigh the added complexity.

Comparing Data Needs in Real Workflows

The question of multi-gas vs single-gas instruments is less about technology and more about decision impact. Ask what actions you take based on gas data.

If your decision tree is simple, for example adjusting ripening schedules based only on ethylene levels, single-gas instruments work well.

If decisions involve adjusting ventilation, modifying atmosphere settings, or explaining unexpected quality outcomes, multi-gas tools provide necessary context.

Research and Quality Assurance

In research settings, multi-gas instruments are often preferred. They allow researchers to correlate ethylene production with respiration and oxygen consumption. This is difficult to do accurately with a single-gas approach.

Quality assurance teams also benefit from multi-gas measurements when validating supplier claims or investigating storage issues. Having oxygen and carbon dioxide data alongside ethylene levels makes reports more defensible and actionable.

Commercial Operations

In commercial packing and storage operations, the choice depends on scale and complexity. Smaller operations with stable processes often succeed with single-gas tools. Larger operations managing diverse commodities and long storage periods tend to rely on multi-gas instruments for better control.

Flexibility and Scalability

Another factor in the multi-gas vs single-gas instruments discussion is future growth. Many operations start with a narrow focus and expand their monitoring needs over time.

Multi-gas instruments offer flexibility when:

-

New commodities are added

-

Storage durations increase

-

Controlled atmosphere programs expand

-

Data reporting requirements become stricter

Single-gas instruments can still play a role in these environments, often as quick-check tools, but they may need to be supplemented as operations scale.

Practical Considerations Beyond Gas Count

While gas capability is central, other factors matter too.

Ease of use and training

Single-gas instruments generally require less training. Multi-gas instruments demand a bit more understanding, especially when interpreting how gases interact. However, modern interfaces and automated calibration have narrowed this gap.

Maintenance and calibration

Multi-gas systems typically involve more sensors, which means more calibration steps. That said, combining sensors into one device can simplify maintenance compared to managing several standalone instruments.

Cost perspective

Upfront cost is higher for multi-gas tools, but total cost of ownership can balance out if one instrument replaces several devices or prevents costly quality losses.

Why Felix Instruments Stands Out

When evaluating multi-gas vs single-gas instruments, the quality of the manufacturer matters as much as the feature list. Felix Instruments designs both single-gas and multi-gas analyzers specifically for produce applications, not adapted from industrial gas monitoring.

Our handheld instruments are built with:

-

Produce-specific sensitivity ranges

-

Portable, field-ready designs

-

Intuitive interfaces for fast sampling

-

Proven performance in research and commercial settings

Because Felix Instruments offers a full range of gas analysis solutions, users are not forced into one approach. You can match the instrument to the task, knowing the measurement philosophy and data quality remain consistent across platforms.

Making the Right Choice

Choosing between multi-gas vs single-gas instruments comes down to understanding how much context you need to make confident decisions. Single-gas instruments deliver speed and simplicity. Multi-gas instruments deliver insight and control.

Before choosing, consider:

-

What decisions are driven by gas data

-

How variable your storage conditions are

-

Whether you expect monitoring needs to expand

-

How critical documentation and traceability are

There is no universal answer, but there is a clear best fit for each operation.

Takeaway

Gas analysis is no longer optional in modern produce handling. Whether you rely on a focused single-gas approach or need the broader insight of multi-gas instruments, the right tool can protect quality, reduce waste, and improve consistency.

Felix Instruments offers both single-gas and multi-gas solutions designed specifically for fresh produce environments. Explore our lineup, talk with our technical team, and choose an instrument that fits your operation today while supporting where you want to go tomorrow.

Related Products

Most Popular Articles

- Spectrophotometry in 2023

- The Importance of Food Quality Testing

- NIR Applications in Agriculture – Everything…

- The 5 Most Important Parameters in Produce Quality Control

- Melon Fruit: Quality, Production & Physiology

- Fruit Respiration Impact on Fruit Quality

- Guide to Fresh Fruit Quality Control

- Liquid Spectrophotometry & Food Industry Applications

- Ethylene (C2H4) – Ripening, Crops & Agriculture

- Active Packaging: What it is and why it’s important