October 20, 2025 at 5:17 pm | Updated October 20, 2025 at 5:17 pm | 7 min read

- Brix is the most common unit used in the food and beverage industry.

- Brix measurement is helpful in crop production, scheduling harvest, quality control, marketing, and processing.

- The use of Brix is widespread because it is easy and inexpensive, and it can be used in fields, storerooms, during transit, in shops, and in processors.

- Nondestructive methods of Brix determination are the best because they are repeatable and require no training or skills from those conducting the soluble solids analysis.

Crop quality measurement is essential throughout the entire fresh produce chain from producers to consumers. Among the various parameters used to measure quality, such as color, firmness, dry matter, titrable acidity, and shape, soluble solids analysis by Brix is the most widely used. Find out the various uses of BRIX in the fresh produce supply chain in this article.

What is Brix?

Adolf Brix developed the °Brix in the mid-1800s to quantify soluble solids in fruits and vegetables. Soluble solids consist mainly of sugars, as well as organic acids, pectins, and amino acids. Brix is used to estimate the sweetness that depends on the amount of sugar in fresh produce and juices.

Brix is equal to the percentage of soluble solids dissolved in water. For example, 100 grams of solution with 50° Brix has 50 grams of sugar and 50 grams of water. The temperature at which Brix is commonly measured is 20°C (68°F).

Subscribe to the Felix instruments Weekly article series.

By submitting this form, you are consenting to receive marketing emails from: . You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact

Sweetness is essential not only for fruits but also for vegetables, including cucumbers, leafy vegetables, and crops like sweet corn. Sweetness determines taste, a significant factor influencing consumer choice of fresh produce and necessary in processing.

Brix is currently the quality parameter that is most used in the fresh produce chain because of the various benefits it offers to all stakeholders- growers, suppliers, managers, processors, restaurateurs, and consumers.

Advantages and Disadvantages of Brix Measurements

Though Brix is versatile, it has advantages and disadvantages that must be understood to apply it in the supply chain.

Advantages

The Brix is popular due to three reasons, according to the Ohio State University Extension:

- Method: °Brix measurements are rapid, objective, reliable, and inexpensive. Measurements can be taken at any stage of fresh produce production in the supply chain.

- Taste indicator: °Brix values can provide an early indication of the sweetness of fruits and vegetables, which is essential to consumers.

- Associated factors: °Brix values are a reflection of several factors, such as variety, growing conditions, maturity at harvest, and storage conditions. Brix can be used to adjust growing and storage conditions throughout a crop cycle to optimize yield quality, as it quantifies the success of strategies aimed at enhancing food production at various stages.

Disadvantages

Brix measurements are repeatable, easily obtained, and can provide an accurate estimate of sweetness. However, due to its limitations, the Brix cannot provide a complete estimate of quality. These limitations are discussed below:

- Reliability: Brix measurements’ reliability depends on sample preparation and the device used for making the estimations. In the case of destructive sampling necessary for using refractometers, the onus falls on the testers. People conducting sugar estimations must have some experience or training to prepare samples properly. This problem can be avoided by using non-destructive Brix estimations, through tools based on Near Infrared spectroscopy, where no sample preparation is necessary, and readings are given in a few seconds by contact with fruits.

- Variability: Crop’s Brix levels depend on genetics (variety) and field management practices. So even the same cultivars from different fields, years, or seasons can produce varying Brix results. It is advisable to take Brix measurements at the same time of day for comparison.

- Not a stand-alone measure: Sweetness is not the only criterion defining taste. In some fruits, the relationship between taste and consumer preference is stronger when measured by Brix. However, in several fruits and vegetables, the acids and other compounds that control taste and flavor can also be crucial. Therefore, fresh produce with the highest Brix is not always the ones that meet consumer satisfaction.

- Not a nutrition indicator: Brix is not a measure of the nutritional value of fresh produce, even though several compounds it measures are necessary for nutrition. So, Brix alone cannot be used to judge the nutritional value of any fresh produce.

Brix is a crucial quality measure, but its optimal use requires data from several crops, fields, climate zones, cultivars, growing conditions, and postharvest handling, along with experience in decision-making at all stages of the supply chain. These applications of Brix are described below.

Preharvest Stages

Brix measurements are used in the preharvest stages for variety selection, crop management, and fixing harvest time.

Variety selection

The amounts of soluble solids and sweetness in fresh produce can vary significantly between cultivars due to genetic variations, resulting in substantial differences in taste within any given fruit. Using the sweeter variety often helps in meeting several market demands, such as those shown below:

- Optimizing taste: Growers who want to enhance flavor in table produce select cultivars based on Brix values. Fresh produce that is better tasting meets consumer preferences that are increasingly more discerning. These consumers may also be those seeking organic food for their superior taste, so organic growers will prioritize Brix values when selecting cultivars to grow.

- Commercial viability: Growers will also choose cultivars with better Brix values, for commercial reasons. Better-tasting food can fetch better prices. Moreover, the chances of rejection are less, increasing ROI.

- Requirements: When fresh produce is grown for processing, growers may need to meet specific Brix standards required by processors.

Crop management

Brix values can be a diagnostic means for growers to understand their crop status. Since growing conditions and management affect Brix values in a crop, farmers take regular Brix measurements to monitor crops. Farmers attempt to manipulate and manage factors to improve Brix readings by fine-tuning irrigation, fertility, and soil management. Since Brix analysis is easy and affordable, farmers can take several readings of their crops to get a more accurate picture of their crop health. Farmers need to have experience and knowledge of their crops and growing conditions to get the full potential Brix of their crops and cultivars.

Scheduling harvest

Brix is a standard harvest maturity index for several types of fresh produce. Brix is the primary internal factor used in the case of non-climacteric fruits, which directly accumulate sugars to ripen instead of storing starch and converting it to sugar later, as climacteric fruits do. For climacteric fruits, the dry matter content also becomes helpful in scheduling harvest.

As fruits mature, the soluble solids content and Brix increase. The Brix or soluble sugar content that fruits should have at full maturity or ripeness is well established for most orchard crops. Growers can take repeated, easy, and inexpensive readings of many trees and fruits, and wait to harvest until the crops have an average of the required Brix levels. The growers can be assured that these fruits, harvested at the recommended Brix, are of good quality, not unripe or overripe, and are sweet and tasty, ensuring consumer satisfaction for eating or processing.

Postharvest Management

In the postharvest stages, Brix is used for quality control during storage, for sorting, grading, pricing, and processing. People use SSC content to monitor the quality of stored fruits, informing decisions on retailing and assuring consumers of high quality.

Sorting, grading, and packaging

Fresh produce is sorted by maturity and ripeness to ensure uniformity in each batch and pallet. Fresh produce batches of uneven ripeness can contain some overripe, ripe, and unripe food, resulting in waste. Batches with uniform Brix and maturity levels allow for optimal segregation and scheduling of fresh produce marketing, thereby minimizing waste and maximizing yield.

Scientists and engineers use Brix measurements to choose and judge the suitability of packaging material or a modified atmosphere for entire or cut fresh produce. The Brix measurements are taken before and after the required length of storage to test the quality of packaging conditions.

Quality control

The quality of fresh produce is monitored during storage and transport to ensure that it meets the standards required by retailers and consumers. It is one of the five most common quality parameters monitored; the others being color, firmness, dry matter content, and titrable acidity. Deteriorating Brix values indicate a need to check and alter storage and transport conditions to maintain fresh produce quality.

Brix can replace expensive and time-consuming tasting panels of experts to establish the quality of fresh produce. Grocery stores and restaurants can use Brix to choose quality fresh produce.

Processing

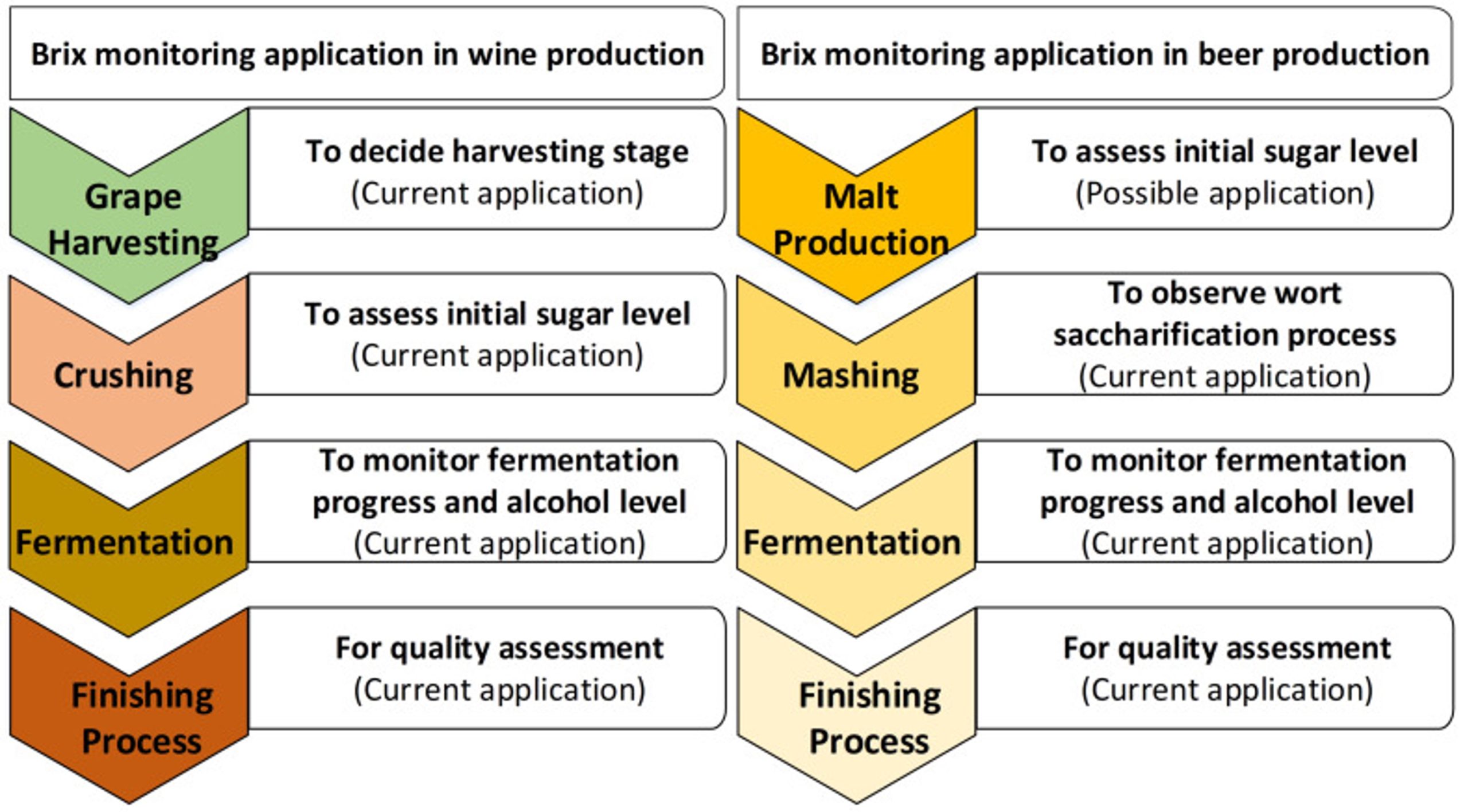

Figure 1: “Brix monitoring at different stages of wine and beer production,” Jaywant et al. 2022. (Image credits: doi: 10.3390/s22062290)

The soluble solids content can significantly influence the processing and quality of value-added products. Sugar levels are crucial for juices, jams, sauces, refined sugar, wine, and beer. Brix values are used at various stages of processing as indicated in Figure 1.

- Choosing: Processors will check Brix values regularly and rely on them to pick fresh produce. Fresh produce with higher Brix indicates less water content, so less expenditure and time to remove it from jams and sauces. Also, higher Brix means less additional sugar must be added to prepare products like jams, which helps control the costs of processing.

- Standardization: In the processing of various products like juices, jams, honey, or concentrates, Brix measurements are essential, as sugar content is the primary constituent.

- Monitoring processing: Sugar content is one of the main compounds monitored during the making of wine and beer, specifically during the crushing/mashing, fermentation, and finishing processes. The amount of sugar at the initial stages allows producers to judge the alcohol content of the finished product.

Brix is thus a vital means of quality analysis from the beginning to the end of fresh produce supply chains.

Reliable Brix Measurements

To ensure that Brix measurements are correct and repeatable, non-destructive methods are preferable over the destructive refractometer. Non-destructive devices, such as those based on Near-Infrared (NIR) spectroscopy, allow the same fruit to be monitored throughout the season because it is not plucked and destroyed for sample preparation. This saves crops, as repeated readings are necessary, involving several fruits each time, in both the preharvest and postharvest stages. Moreover, the NIR readings are precise, and results are obtained in real time in easy-to-understand, actionable values. NIR readings are also helpful during processing, used offline, online, or inline. Felix Instruments Applied Food Science produces several quality meters, both general and customized for specific fruits, to measure Brix on the go.

Discover more about Felix Instruments’ Quality Meters for measuring Brix in your fresh produce supply chain.

FAQ

1. What is Brix, and how is it measured?

Brix (°Brix) measures the percentage of soluble solids, mainly sugars, along with acids and amino acids, in a liquid. It indicates sweetness in fruits, vegetables, and juices. A 10° Brix solution means there are 10 grams of sugar in 100 grams of liquid. Measurements are usually taken at 20°C (68°F) using tools like refractometers or non-destructive Near Infrared (NIR) devices.

2. How is Brix used in agriculture and food processing?

Brix plays a key role throughout the food supply chain:

- Preharvest: selecting varieties, managing crops, and determining the best harvest time.

- Postharvest: sorting, grading, and monitoring quality during storage and transport.

- Processing: ensuring consistent sugar levels in juices, jams, wines, and other products.

3. What are the advantages and disadvantages of using Brix measurements?

Advantages:

- Fast, inexpensive, and objective.

- Provides an early indicator of sweetness and ripeness.

- Reflects growing conditions and can guide quality improvements.

Disadvantages:

- Results can vary depending on crop variety and conditions.

- Doesn’t fully reflect taste or nutritional value.

- Destructive testing methods can waste samples, though non-destructive NIR tools can avoid this.

Sources

Jaywant, S. A., Singh, H., & Arif, K. M. (2022). Sensors and Instruments for Brix Measurement: A Review. Sensors (Basel, Switzerland), 22(6), 2290. https://doi.org/10.3390/s22062290

Kleinhenz, M.D., & Bumgarner, N. R. (2013, Jan 18). Using °Brix as an Indicator of Vegetable Quality: An Overview of the Practice. Retrieved from https://ohioline.osu.edu/factsheet/HYG-1650#:~:text=%C2%B0Brix%20values%20are%20important%20because%20they%20can,production%20including%20irrigation%2C%20fertility%2C%20and%20post%2Dharvest%20management.

Kleinhenz, M.D., & Bumgarner, N. R. (2015, Sep 18). Using °Brix as an Indicator of Vegetable Quality: Instructions for Measuring °Brix in Cucumber, Leafy Greens, Sweet Corn, Tomato, and Watermelon. Retrieved from https://ohioline.osu.edu/factsheet/hyg-1653

Related Products

Most Popular Articles

- Spectrophotometry in 2023

- The Importance of Food Quality Testing

- NIR Applications in Agriculture – Everything…

- The 5 Most Important Parameters in Produce Quality Control

- Melon Fruit: Quality, Production & Physiology

- Fruit Respiration Impact on Fruit Quality

- Guide to Fresh Fruit Quality Control

- Liquid Spectrophotometry & Food Industry Applications

- Ethylene (C2H4) – Ripening, Crops & Agriculture

- Active Packaging: What it is and why it’s important