Latest uncategorized

From the Stage at Fruit Logistica 2026: Rethinking Freshness with 500,000 Data Points

At Fruit Logistica Berlin 2026, we presented insights from more than 500,000 non-destructive fruit quality scans collected across global growing regions, multiple seasons, and every stage of the supply chain. What this dataset reveals is simple but consequential: most quality control systems are built around averages, while the real economic damage comes from the extremes.… Continue reading…

Additional reading

What Are the Most Common Apple Quality Issues and How Can They Be Prevented?

The primary quality issues with apples are water loss, physiological disorders, storage disorders, microbial decay, and mechanical injuries. Some of the factors that influence post-harvest apple quality include harvest maturity, storage conditions, proper handling, and growing conditions throughout the supply chain. The susceptibility of apples to quality problems can vary by cultivar; therefore, growing, storage,… Continue reading…

How to Prevent Postharvest Quality of Table Grapes from Declining During Storage and Transport

Gray mold infection and rachis browning are the two main factors responsible for post-harvest quality loss of table grapes. Loss of appearance, weight, and firmness, shriveling, wilting, and bruising are some of the other prominent quality issues seen in postharvest grape clusters. Rapid moisture loss in berries, handling, and diseases are the three major postharvest… Continue reading…

What Is an Ethylene Monitoring System and Why Is It Critical for Fresh Produce?

Ethylene monitoring systems can have fixed or portable sensors. Other components of the monitoring systems could be data logging, data transmission, connectivity, remote access, and a control event scheduler. The sensors used to detect ethylene must be sensitive, selective, stable, rapid, and have the required lower limit and detection range. Ethylene monitoring in the postharvest… Continue reading…

How to Detect and Control Ethylene in Storage Rooms

Ethylene must be monitored and controlled as even trace amounts in parts per billion can cause over-ripening, decay, and spoilage. Fixed and portable gas analyzers that can detect and monitor ethylene levels in storage facilities are available on the market. Several strategies exist to lower ethylene levels, including venting, the use of ethylene inhibitors, scrubbers,… Continue reading…

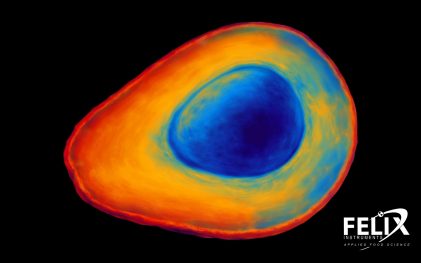

What Causes Avocado Quality Problems? Common Issues in the Supply Chain Explained

Avocados are challenging due to their unique ripening process, which requires a few days post-harvest to overcome the “tree factor.” The leading causes of quality problems are incorrect maturity at harvest, careless handling, and improper storage temperatures and gas mixtures in cool storage. Limiting problems starts with harvesting avocados at the correct maturity and quality… Continue reading…

What Are the Harvest Maturity Indices for Strawberries?

Strawberries can be harvested at two different maturities to meet marketing needs at varying distances. Color is the most critical parameter used as a maturity index for strawberry harvest. Other harvest maturity indices are size, sugar content, and taste. Non-destructive measurements using portable NIR spectroscopy devices are best suited for establishing harvest maturity indices. Strawberries… Continue reading…