September 25, 2023 at 3:48 pm | Updated September 25, 2023 at 3:48 pm | 9 min read

- Scientists seek solutions to local mango postharvest challenges to extend shelf life, maintain quality, and reduce waste, disease, and pest damage.

- Studies often focus on finding eco-friendly alternatives to existing chemical treatments.

- Measurement of physicochemical quality parameters is a standard procedure in the search for appropriate postharvest technology.

Mango (Mangifera indica L.) is a tropical fruit popular globally for its taste and aroma. Globally, it is one of the top ten fruits that is produced. It is a significant source of income and nutrition in the countries where it is grown. Mango Postharvest Technologies are vital for addressing Mango’s short shelf-life and difficulties in maintaining and regulating its postharvest quality.

-

External Ethylene for Peel Color Transformation

Figure 1. “Effects of ETH treatment on peel color transformation in postharvest mango fruit. Photos were taken on 0, 6, 9, and 12 days after treatment,” Chen et al. 2022. (Image credits: https://doi.org/10.3389/fnut.2022.911542)

Subscribe to the Felix instruments Weekly article series.

By submitting this form, you are consenting to receive marketing emails from: . You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact

Mango is a climacteric fruit, and it is picked at physiological maturity and later treated artificially with ethylene to ripen it according to retail demand to achieve its commercial color and flavor.

Ethylene is a natural phytohormone secreted by plants. It triggers ripening and is essential for developing mango color, texture, flavor, and nutritional quality. Mango colors can be green, yellow, orange, or red. Immature mangos have more chlorophyll that masks carotenoids and anthocyanins.

The effect of ethylene on mango color is affected by many factors, such as other plant hormone levels and storage conditions. Location and local conditions, such as in China, can complicate efficient postharvest mango storage.

To find ripening solutions targeted for local conditions, a team of Chinese scientists investigated the effect of different concentrations of Ethephon [(2-chloroethyl) phosphonic acid, ETH], an artificial ethylene analog, on “Guifei” the main mango variety produced in Hainan, China when stored at 25°C. They tested the external application of ethylene on the ripening process and color changes until 15 days after treatment.

The research findings showed that postharvest treatments of mango with 300, 500, and 900 mg·L−1 ETH accelerated color transformation and fruit softening. The scientists found that the “Guifei” mango color transformation by ETH depended on increasing solution concentrations, as shown in Figure 1. The 900 mg·L−1 ETH treated fruits have undergone the most color changes, followed by the 300 mg·L−1 ETH and then the 300 mg·L−1 ETH treatments.

ETH stimulated the activities of ACS and ACO, resulting in endogenous ethylene release. The treated mangoes showed a chlorophyll breakdown due to more activity by enzymes Chlase and MDCase. The scientists found that ETH had increased the expression of the genes PAL, CHI, DFR, and UFGT, which controlled the synthesis of the carotenoid and anthocyanin, as shown in Figure 2. Two genes in particular, DFR and UFGT, were more active than in controls.

As the ETH-induced endogenous ethylene production increased, fruit firmness and chlorophyll content fell, but anthocyanin and MDA content rose.

The treated mangos had higher MDA levels and lower firmness, so internal quality development was also positive.

Figure 2. “The mode of action of ETH on mango fruit ripening and color transformation,” Chen et al. 2022. (Image credits: https://doi.org/10.3389/fnut.2022.911542).

-

Eco-friendly Coatings to Improve Mango Quality and Shelf-Life

Mango fruits continue to respire and transpire even after harvest. During respiration, they use stored carbohydrates to release carbon dioxide (CO2); they lose water vapor during transpiration. Both these physiological activities reduce fruit weight and shorten the shelf-life. Moreover, fruits are also prone to microbial attack and pests.

Coatings are a popular way to maintain fruit quality, extend shelf life, and reduce wastage during transport and storage. The coatings create a modified atmosphere that reduces respiration by blocking oxygen; ethylene production triggered by respiration is also reduced, prolonging fruit shelf life. Moreover, the coatings act as a barrier to microbes and pests.

Instead of using chemicals, the industry is increasingly turning to Mango Postharvest Technologies like edible coatings that protect fruits till consumption and are readily degradable in garden compost heaps. Such sustainable coatings reduce health risks to consumers and are environmentally friendly.

Figure 3: “Effect of coating materials and storage durations on total soluble solids of mango fruit,” Fatima et al. 2022. (Image credits: DOI:10.15835/nbha50412917)

An international team tested peanut, sunflower, corn, soya bean, and animal fat to find suitable edible oil coatings for mangos. They applied the oils after the mango variety ‘Anwar Rataul’ was harvested at physiological maturity and when they were still firm and green. The coated and uncoated control mangos were stored at 25 °C and a relative humidity of 75 percent, and their quality was monitored for 25 days.

Uncoated fruits rotted in 20 days. The coatings significantly impacted quality by slowing down the ripening process and the development of color, aroma, and taste, which prolonged the shelf-life. Peanut oil had the most effect, followed by soybean oil. After twenty days, color, aroma, and taste declined in coated mangos.

At the end of the experiment, after 25 days, animal fat-coated mangos had the most color, aroma, and taste, followed by sunflower oil-coated mangos. The animal fat-coated mangos had the most total sugars and total soluble sugar (TSS) content, ascorbic acids, titrable acidity, less weight loss, and delayed ripening. They had low pH, which increases shelf-life.

The scientists concluded that animal fat showed the best results, followed by sunflower oil.

-

Mango Postharvest Technologies: Handling and Jam Evaluation

Mango is the second most economical fruit cultivated in Ethiopia. Mango is a seasonal crop, and a glut leads to low market prices. Processing seasonal excesses adds value, creates internationally competitive products, and prevents waste. It allows mango to be enjoyed throughout the year, increases income, and decreases production costs. Jam preparation is one of the best-suited techniques in Ethiopia for mango preservation.

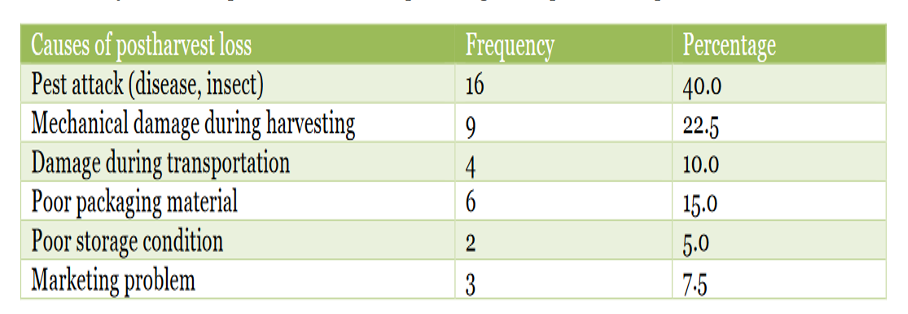

Table 1: “Major causes of postharvest loss and percentage of respondents at producer’s level,” Gutema and Tadesse, 2022. (Credits: DOI: https://doi.org/10.3329/ijarit.v12i1.61046)

The present study assessed postharvest handling practices to find a way to demonstrate and popularize mango jam-making in south Ethiopian rural households.

Around 40 farmer households (28 female and 12 male) were interviewed about postharvest handling and jam sensory qualities. Over 87.5 percent of the respondents were above 25 years old, and 40 percent had varying levels of school education.

Results of the study showed that 42.5 percent of transport involved pack animals like donkeys, mules, and horses; car transport (30 percent) and humans (22.5 percent) were other modes used. The sack was the common packing material used in 47.5 percent of cases, followed by baskets and plastic baths.

The major reasons for mango loss were identified by respondents, and pest and insect damage emerged as the top reason. The second reason was mechanical damage and fruit injuries due to rough handling during harvest. Loading and unloading, tight packaging of fruits, transportation over bad roads, and use of inefficient packing material were other reasons for mango loss. Local mango jam was evaluated for appearance, color, and flavor and received a score of four on a 5-point scale, indicating it was highly acceptable.

To remedy the identified problems, scientists recommend using Mango Postharvest Technologies such as pest and disease-resistant cultivars, better harvesting methods, storage, and transportation services. These technologies are aimed to reduce mango waste and extend shelf-life.

Based on the results, the two scientists developed a manual and practical training program on postharvest handling, processing, and mango jam use that was widely distributed to development agencies, administrators, and farmers.

-

Pomelo Extract against Anthracnose in Postharvest Mango

Figure 4. “Pomelo extract inhibits Colletotrichum gloeosporioides in vitro and in vivo. (A) The inhibition curve and IC50 of PE against C. gloeosporioides were determined by in vitro assays. (B) The disease index of fruit treated with water, chitosan solution (CS), CS incorporated with 10 mL L−1 PE (P10), or 20 mL L−1 PE (P20). (C–G) Evaluation of physiological traits of fruit- chroma (C), hue (D), firmness (E), total soluble solids (F), and titratable acids (G), respectively,” Cheng et al. 2022. (Image credits: https://doi.org/10.3390/plants11152064)

Mangos are susceptible to anthracnose, the common fungal disease affecting many fruits in the postharvest stage. The fungal Colletotrichum species infect the fruit when they are immature. The condition becomes apparent as the fruit starts ripening, showing characteristic symptoms like sunken skin and lesions, damaging the quality and value of fruits. Anthracnose leads to significant loss of postharvest mangos.

Conventionally, chemical fungicides were used, but consumers prefer natural alternatives due to health and environmental concerns.

Pomelo would be an ideal alternative as its thick peel, accounting for 30 percent of its weight, is currently wasted. Pomelo extract (PE) is effective against many microbes, but its effect against anthracnose is unknown.

Therefore, a group of scientists from Taiwan studied PE chemical profile and anti-anthracnose action using in vivo and in vitro assays. The scientists also tested the impact of different storage temperatures ranging from 20° to −80 °C and light conditions on PE composition and anti-anthracnose effect.

The scientists found the percentages of seven important constituents in PE and d-limonene among them was responsible for the anti-anthracnose effect. Of all the treatments, the chitosan-based coating with 20 mL L−1 PE suppressed anthracnose in ‘Keitt’ mangos. Storage temperatures below 5°C were preferable to preserve PE composition and antifungal activity.

Estimating color, firmness, and TSS showed that PE didn’t affect the ripening process. Firmness and titratable acidity were reduced, TSS levels increased, and color changes were observed as ripening proceeded unaffected by PE.

The scientists were able to recommend PE as a sustainable anti-anthracnose measure for mangoes as well as other postharvest crops.

-

Evaluation of Markers Associated with Mango Physiological and Biochemical Changes

Figure 5. “Typical NIR spectra of ‘Nam dok mai si thong’ mango encountering physical and biological damages during the storage in the wavelength range of 800–2400 nm (A) and multivariate analysis (PCA) score plot computed from the spectral data (B),” Tangpao et al. 2022. (Image credits: https://doi.org/10.3390/agriculture12091407)

Nam dok mai si thong’ is a mango cultivar with high global demand.

At ambient temperatures, harvested mangos that have reached maximum ripening have a short shelf-life of just 4–8 days. Fruit respiration and transpiration, ripening, pests, and disease reduce shelf-life and fruit quality and cause a loss of 45 percent of mangos.

A team of mainly Thai scientists wanted to understand the role of specific postharvest markers in the ripening process, disease and physical damage, and essential oil burning of ‘Nam dok mai si thong’ mango. The markers studied were physicochemical properties like firmness, titratable acidity, total and reducing sugar contents, peel electrolyte leakage, antioxidants, total phenolic and flavonoid compounds, weight loss, and peel color.

The scientists estimated the markers with near-infrared (NIR) spectroscopy. They used partial least squares correlation models and chemometric analysis to analyze the NIR spectra to correlate them with postharvest physiological changes, see Figure 5.

The parameters correlated with the ‘Nam dok mai si thong’ mango ripening were color (lightness L* and b* value), pH, and total soluble solids. These three parameters/markers were also associated with changes during physical damage and disease infection. The NIR spectra useful in identifying biochemical changes were absorbance at 1170 nm, 1400–1500 nm, and 2150–2250 nm.

The scientists consider the findings an initial step in developing a quality assessment method for ‘Nam dok mai si thong’ mango.

F-751 Mango Quality Meter

In most studies that aim to find postharvest methods and innovations appropriate for local mango growing conditions, measurement of physiochemical quality parameters is crucial. A tool like the Felix Instruments’ F-751 Mango Quality Meter can be useful for making real-time, non-destructive, precise quality estimations. The device uses NIR spectroscopy and wavelengths between 640-1050 nm and can measure total soluble solids and dry matter. The F-751 Mango Quality Meter is also calibrated for many popular global varieties, and models can be customized for others using the easy model-building information provided by the firm.

In research that searches for sustainable and eco-friendly postharvest technologies for mango, F-751 can avoid waste even during study.

Sources

Chen, M., Gu, H., Wang, L., Shao, Y., Li, R., & Li, W. (2022). Exogenous ethylene promotes peel color transformation by regulating the degradation of chlorophyll and synthesis of anthocyanin in Postharvest Mango Fruit. Frontiers in Nutrition, 9. https://doi.org/10.3389/fnut.2022.911542

Cheng, Y.-J., Wu, Y.-J., Lee, F.-W., Ou, L.-Y., Chen, C.-N., Chu, Y.-Y., & Kuan, Y.-C. (2022). Impact of storage condition on chemical composition and antifungal activity of pomelo extract against Colletotrichum gloeosporioides and anthracnose in postharvest Mango. Plants, 11(15), 2064. https://doi.org/10.3390/plants11152064

Fatima, F., Basit, A., Ahmad, A., Shah, S. T., Sajid, M., Aman, F., Mohamed, H. I., & Elhakem, A. (2022). Enhancement of the fruit quality and postharvest life expectancy of mango fruit (Mangifera indica L.) applying ecofriendly bio-coatings. Notulae Botanicae Horti Agrobotanici Cluj-Napoca, 50(4), 12917. https://doi.org/10.15835/nbha50312917

Gutema, T., & Tadesse, A. (2022). Assessment of postharvest handling of Mango and evaluation of Mango Jam in major mango producing areas of South Omo Zone, SNNPR, Ethiopia. International Journal of Agricultural Research, Innovation and Technology, 12(1), 155–160. https://doi.org/10.3329/ijarit.v12i1.61046

Shahbandeh, M. (2023, January 5). Fruit: World production by type 2021. Statista. https://www.statista.com/statistics/264001/worldwide-production-of-fruit-by-variety/

Tangpao, T., Phuangsaujai, N., Kittiwachana, S., George, D. R., Krutmuang, P., Chuttong, B., & Sommano, S. R. (2022). Evaluation of markers associated with physiological and biochemical traits during storage of ‘Nam Dok Mai Si Thong’ mango fruits. Agriculture, 12(9), 1407. https://doi.org/10.3390/agriculture12091407

Related Products

Most Popular Articles

- Spectrophotometry in 2023

- The Importance of Food Quality Testing

- NIR Applications in Agriculture – Everything…

- The 5 Most Important Parameters in Produce Quality Control

- Melon Fruit: Quality, Production & Physiology

- Fruit Respiration Impact on Fruit Quality

- Guide to Fresh Fruit Quality Control

- Liquid Spectrophotometry & Food Industry Applications

- Ethylene (C2H4) – Ripening, Crops & Agriculture

- Active Packaging: What it is and why it’s important