February 5, 2026 at 10:37 pm | Updated February 5, 2026 at 10:37 pm | 5 min read

Choosing the right produce quality meter is a decision that affects data quality, operational efficiency, and long-term return on investment.

Whether you are running field trials, managing postharvest storage, or making rapid commercial decisions on fruit maturity, the difference between a research-grade instrument and a commercial-use quality meter matters.

At first glance, many quality meters look similar. They are handheld, promise fast results, and claim to be nondestructive.

Subscribe to the Felix instruments Weekly article series.

By submitting this form, you are consenting to receive marketing emails from: . You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact

The real differences show up in how the data is generated, how flexible the system is, and how well the instrument fits into real workflows. Understanding these distinctions helps ensure you invest once and invest well.

What Defines a Produce Quality Meter

A produce quality meter is designed to estimate internal attributes such as dry matter, Brix, firmness proxies, or gas concentrations without cutting open the fruit.

Most modern systems rely on near-infrared spectroscopy or gas analysis. The goal is speed and repeatability while preserving the sample.

Where meters diverge is in calibration depth, sensor quality, software control, and long-term support. These factors separate research-grade instruments from tools designed primarily for routine commercial checks.

Research-Grade Quality Meters Explained

Research-grade produce quality meters are built for precision and adaptability. They are typically used by universities, breeding programs, and R&D teams where understanding variability matters as much as speed.

Key characteristics include:

-

Advanced sensors with higher spectral resolution

-

User access to raw or semi-processed data

-

Custom calibration development and refinement

-

Support for experimental designs and multiple crops

-

Software designed for analysis, not just pass or fail decisions

In practice, this means a researcher can build a calibration for a specific cultivar, region, or season. They can also adjust models as conditions change. This flexibility is critical when data is used for publications, grant work, or long-term breeding decisions.

A research-grade produce quality meter is also more forgiving of complexity. It assumes the user understands sampling protocols and statistical validation. The reward is deeper insight and confidence in the results.

Commercial-Use Quality Meters Explained

Commercial-use quality meters prioritize speed, simplicity, and repeatability. These tools are common in packinghouses, distribution centers, and quality assurance programs where decisions must be made quickly.

Typical features include:

-

Pre-installed, crop-specific calibrations

-

Minimal setup and training requirements

-

Simple user interfaces

-

Fast measurement cycles

-

Durable hardware designed for daily use

A commercial produce quality meter is often used to sort lots, verify maturity thresholds, or monitor consistency across shipments. The emphasis is on actionable results rather than data exploration.

While these meters may not offer the same level of calibration control, they excel at delivering consistent results across operators and locations.

Where Research-Grade and Commercial Tools Overlap

The line between research-grade and commercial-use quality meters has blurred in recent years.

Some instruments are designed to serve both roles effectively. This hybrid approach is especially valuable for organizations that operate across research, production, and quality control.

This is where Felix Instruments stands out. Our produce quality meter lineup is designed with modularity and scalability in mind. Instruments like the F-750 Produce Quality Meter and the crop-specific F-751 series are used in academic research and commercial operations alike.

A single platform can move from calibration development in trials to routine checks in commercial settings without changing hardware. That continuity reduces training time and improves confidence in the data.

Data Quality and Calibration Flexibility

One of the biggest differences between instrument classes is how calibrations are handled. Research-grade systems allow users to build, validate, and adjust models. Commercial systems often lock calibrations to ensure consistency.

Felix Instruments bridges this gap by offering robust factory calibrations while still allowing advanced users to refine models when needed. This is especially useful for operations dealing with multiple growing regions or seasonal variability.

A produce quality meter that adapts over time reduces the risk of model drift and keeps measurements aligned with real fruit physiology.

Cost Considerations Beyond the Sticker Price

It is tempting to evaluate quality meters based solely on upfront cost. This often leads to underinvestment. A lower-cost instrument that cannot adapt or scale may need replacement sooner or deliver data that limits decision-making.

When evaluating cost, consider:

-

Calibration longevity and update options

-

Support and training availability

-

Ability to expand to new crops or attributes

-

Data consistency across seasons

A research-grade capable produce quality meter may cost more initially, but it often delivers better long-term value, especially for operations that evolve.

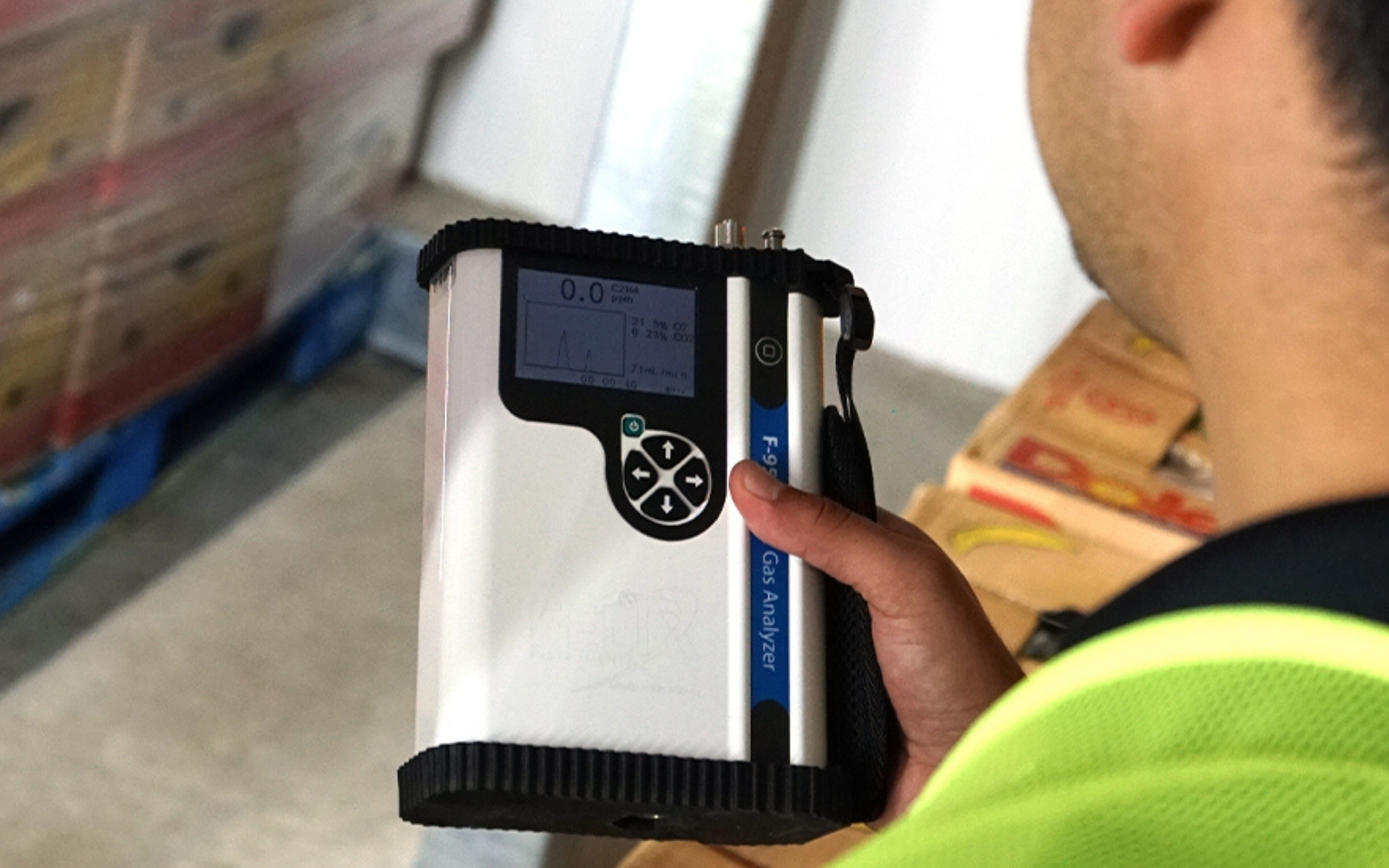

Gas Analysis as Part of Quality Assessment

Quality is not only about sugars and dry matter. Gas composition plays a critical role in ripening and storage outcomes. Instruments that measure ethylene, oxygen, and carbon dioxide complement NIR-based quality meters.

Felix Instruments offers portable gas analyzers that integrate well into postharvest workflows. These tools help link internal quality measurements with ripening behavior, providing a more complete picture of produce condition.

For many users, combining gas analysis with a produce quality meter leads to better storage decisions and reduced losses.

Choosing the Right Tool for Your Operation

The right choice depends on how you plan to use the data.

A research-grade leaning produce quality meter makes sense if you:

-

Develop or refine calibrations

-

Work with new cultivars or crops

-

Require defensible, traceable data

-

Support long-term research or breeding programs

A commercial-use focused produce quality meter is ideal if you:

-

Need fast, repeatable decisions

-

Train multiple operators

-

Monitor quality at scale

-

Prioritize operational efficiency

Many organizations fall somewhere in between. In those cases, a flexible platform offers the best of both worlds.

Final Thoughts

Investing in a produce quality meter is not just a hardware decision. It is a choice about data confidence, workflow efficiency, and future capability.

The gap between research-grade and commercial-use instruments is narrowing, and modern systems can serve both roles effectively.

Felix Instruments has built its quality meters with this reality in mind. Our tools are used globally in research labs, orchards, packinghouses, and storage facilities. If you are evaluating your next produce quality meter, consider how flexibility, support, and data integrity factor into your long-term goals.

To learn more about selecting the right instrument for your application, connect with Felix Instruments and explore how our quality meters can support your operation from research through commercialization.

Frequently Asked Questions

What Is the Main Difference Between a Research-Grade and Commercial-Use Produce Quality Meter?

The main difference is flexibility. Research-grade meters allow calibration development and deeper data access, while commercial-use meters focus on speed and simplicity.

Can One Produce Quality Meter Be Used for Both Research and Commercial Applications?

Yes. Some modern platforms, including those from Felix Instruments, are designed to transition seamlessly between research and commercial workflows.

Is a Higher-Cost Quality Meter Always Better?

Not always, but higher-quality instruments often provide better long-term value through adaptability, support, and data reliability.

Related Products

Most Popular Articles

- Spectrophotometry in 2023

- The Importance of Food Quality Testing

- NIR Applications in Agriculture – Everything…

- The 5 Most Important Parameters in Produce Quality Control

- Melon Fruit: Quality, Production & Physiology

- Fruit Respiration Impact on Fruit Quality

- Guide to Fresh Fruit Quality Control

- Liquid Spectrophotometry & Food Industry Applications

- Ethylene (C2H4) – Ripening, Crops & Agriculture

- Active Packaging: What it is and why it’s important