August 4, 2025 at 4:37 pm | Updated August 4, 2025 at 4:37 pm | 7 min read

- Dry matter is measured on farms to monitor maturity and determine the optimal harvest time for climacteric fruits and vegetables.

- In the postharvest stage, dry matter is used for quality control for sorting and grading fresh produce.

- Dry matter determines the storage, transport, and ripening conditions to achieve optimum quality and extended shelf life.

- Wholesalers, distributors, and retailers use dry matter measurements to comply with national, international, and retailer-specific quality standards.

Dry matter content is the latest quality parameter that is used by the fresh produce supply chain, as it gives objective and quantitative information on the internal condition of fruits and vegetables. Measuring dry matter can improve the quality of fresh produce reaching consumers, reduce food loss, and improve profits for the supply chain. This article examines the various applications of dry matter measurements in the fresh produce supply chain, which support the achievement of these objectives.

What Is Dry Matter?

Dry matter refers to the solid contents in plants, excluding water. Dry matter includes non-structural carbohydrates like sugars and starch, structural carbohydrates like cellulose and hemicellulose, oils, amino acids, proteins, lipids, vitamins, pigments, antioxidants, minerals, volatile compounds, etc.

Dry matter is measured before fresh produce is harvested and during the post-harvest stages. Between flower fertilization and maturity, there is a 100-fold increase in dry matter. Various compounds are used in cell division as the fruit develops, and the cells expand. During development, fruits act as sinks for biomass allocated by the plants.

Subscribe to the Felix instruments Weekly article series.

By submitting this form, you are consenting to receive marketing emails from: . You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact

Fruits differ in the types of compounds they accumulate, based on species and cultivars, which explains the differences in shape, size, color, taste, and flavor of fresh produce. Significant differences in compound accumulation trends and the ratios in which they are present in the fruits can change during maturation, determining the ripening mode.

- Climacteric fruits accumulate non-structural carbohydrates, such as starch, that are converted into sugars during ripening. It allows fruits to be harvested when fully mature but still unripe, thereby extending the time for transport and storage. Ripening is controlled and undertaken when needed for retailing. Dry matter measurement is very crucial for this category of fresh produce.

- Non-climacteric fruits accumulate non-carbohydrates as sugars and not starch. These fruits need to be on the plant to ripen, and are harvested just before they get fully ripe.

Dry matter is measured to determine the maturity of fruits as they develop, fix harvest time, and establish quality. These measurements begin before harvest and extend throughout the postharvest stages of the supply chain.

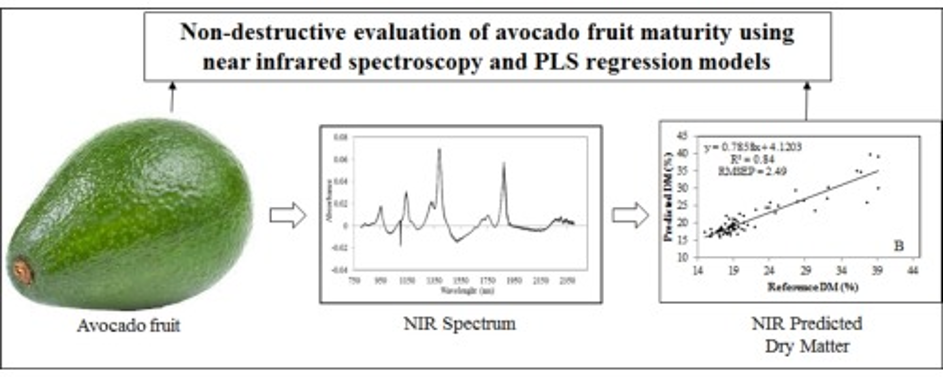

Figure 1: Graphical abstract of NIR estimation of dry matter in avocado, Olarewaju et al. (2016). (Image credits: https://doi.org/10.1016/j.scienta.2015.12.047)

Measuring Dry Matter Content

Staff in fresh produce supply chain facilities find testing dry matter in the laboratory challenging, as the procedure requires specialized expertise. Therefore, the tests can be outsourced, which delays the receipt of results.

Near-infrared (NIR) spectroscopy-based instruments offer an alternative that can provide non-destructive, precise, easy, and rapid measurements and results on-site. Quality assessment tools provided by Felix Instruments Applied Food Science include the general F-750 Produce Quality Meter and the F-751 series, which is customized for various fresh produce, such as mango, avocado, grape, kiwifruit, and melon. The tools are small and portable, designed for on-site use in the supply chain, and require no special training for operation.

A 2021 German study evaluating the dry matter content of avocados, apples, blueberries, grapes, and tangerines showed that the F-750 Produce Quality Meter was one of the portable instruments that can accurately and quickly determine dry matter content non-destructively. NIR light from the tool directed at the fruits interacts with their bio compounds. The tool then measures the NIR light absorbed by the fruit, and a trained model analyzes the spectral data to provide the dry matter content in easy-to-understand percentages within seconds (see Figure 1).

People involved in the postharvest fresh produce supply chain who can benefit from non-destructive dry matter assessment include those in production, trade, logistics, and retail phases:

- Fruit and vegetable production involves farmers and cooperatives.

- Trade includes fresh produce wholesalers and distributors who sell to retailers.

- Logistics covers storage and transport.

- The retail market has direct contact with end consumers.

Fruits and Vegetable Production Stage

During the production stage, dry matter can be used to measure maturity and determine harvest time.

It is used as a harvest maturity index for several climacteric fruits and vegetables. Dry matter content increases as maturity progresses. Fruits that ripen on trees will have the maximum dry matter content. However, the optimum dry matter content for harvest is not the maximum, but rather the percentage that allows fruits to ripen properly post-harvest and yet extends the time for transport and storage. The optimum dry matter will vary with species and cultivars and has been fixed for most fruits.

Since starch is converted to sugar during ripening, dry matter at harvest is a reliable indicator of postharvest fruit quality or taste. Many studies have shown that the optimum dry matter content at harvest yields fruits that taste good and meet consumer satisfaction in retail shops. For items such as avocados, dry matter is a suitable indicator of oil content, which serves as the required harvest maturity index.

Brix, which measures sugar content, is a better indicator of the harvest time for non-climacteric fruits.

In many parts of the world, production companies send consultants to farms that still use optical inspection or manual estimation of firmness through pressure to estimate harvest time. NIR-spectrometers can be used to measure the dry matter of fresh produce on the plant without waste, helping farmers predict harvest time. In large orchards, it can help in planning harvest operations.

Fruits must meet national and international maturity standards. Dry matter testing is used as it is objective and quantifiable. For example, in New Zealand, maturity clearance testing is used to determine the optimal maturity level for each avocado season within a specific maturity area. A single maturity clearance area can have up to five hectares, from which one maturity clearance sample of 20 fruits is taken; large orchards can have more than one clearance area. Since dry matter is monitored regularly on the farms, once the required dry matter content is reached, a blanket clearance is given, so fruits in that maturity area do not have to be tested further.

Sorting and Grading

Dry matter is checked at several critical points during the sorting of fresh produce.

The first step occurs at the farm or packinghouse, where produce is sorted and graded based on its dry matter content for climacteric fruits. It prevents fruits at different stages of maturity from being mixed in a pallet or batch to avoid checkerboard ripening, where fruits can ripen at various times and have varying shelf lives, resulting in the rejection and loss of overripe or unripe fruits. Additionally, overripe fruits can spoil or hasten the ripening of other fresh produce in the batch or nearby due to the release of ethylene.

Fruits are also graded based on the amount of dry matter, with higher content signifying better taste and value.

Wholesale and Distribution

At wholesalers, the dry matter content is measured to verify the quality of both incoming fresh produce over several weeks. Incoming fresh produce must meet minimum quality criteria. Additional conditions by retailers must also be fulfilled, even in the case of packaged fresh produce. NIR tools that can measure the quality of packaged fresh produce offer an advantage over traditional methods. Open stored goods can also be examined on their pallet, speeding up work with minimum disruptions to the goods flow.

Being able to quickly test and get an average of several fruits is a more reliable indicator of quality than single samples. Wholesalers use dry matter measurements for several purposes listed below:

- Estimate quality fluctuations over a season

- Assess shelf life and send more mature produce for processing to avoid food loss

- Ascertain the region of origin of fresh produce

- Check individual suppliers’ goods

Wholesalers and distributors have their own or third-party logistics, respectively, where information on dry matter is helpful.

Storage, Transport, and Ripening Conditions

Controlled atmosphere (CA) storage and transport are commonly used, especially in long-distance supply chains. These facilities strictly regulate temperatures, relative humidity, and gas concentrations of oxygen, carbon dioxide, and ethylene to maintain quality, control ripening, and extend the shelf life of all fresh produce. The exact combinations of the atmospheric conditions and gas levels will depend on the maturity of fresh produce.

While CA units control ripening, special ripening rooms facilitate ripening by raising temperature and ethylene gas levels, just after fresh produce arrives in the importing country. Again, the conditions, as well as the duration of ripening, will depend on the maturity of the fresh produce.

Several problems, such as uneven ripening, slow color development, and poor flavor, can occur if the fresh produce has a low dry matter content and the temperatures are not adjusted accordingly, for example, in avocados. Fresh produce with high dry matter can experience fast ripening or have a shorter shelf life. Hence, it is essential to check the dry matter several times during the postharvest stages to sort and plan for goods that should be used, ripened, and sold sooner to minimize waste.

Harvesting fresh produce at the correct maturity can help in preventing most problems at the ripening stage.

At The Retailers

Quality and ripening testing occur at retailers, as they have standards that wholesalers must meet. These facilities will inspect the quality of incoming fresh produce through dry matter measurements for specific foods, such as potatoes. For most fresh produce, it is the sugar content that is checked at this stage.

- Retailers monitor dry matter to ensure the marketing and commercial standards of origin are met. The dry matter content can be used to grade fresh produce.

- Retailers can utilize the dry matter data to establish prices for premium-quality products and effectively convey their value to health-conscious consumers.

- The dry matter content of incoming fresh produce will also inform retailers of possible shelf life and inform decision-making on which batches to sell first, thereby avoiding food loss and improving profits.

Reducing Loss and Improving ROI

Estimating dry matter at different stages enables concerned stakeholders to optimize quality, reduce spoilage and food loss, and improve profit margins. When non-destructive NIR devices are used, labor time is cut, enhancing efficiency and profits. When a greater percentage of fruits and vegetables are sold and utilized, it also helps achieve food sufficiency and make the supply chain more sustainable.

Find out how Felix Instruments Applied Food Science can help with your fresh produce maturity and quality control needs.

Sources

Allará, C., Moscetti, R., Bedini, G., Ciocca, M., Benelli, A., Lugli, P., Petti, L., & Ibba, P. (2025). Bioimpedance-based prediction of dry matter content and potato varieties through supervised machine learning methods. Postharvest Biology and Technology, 222, 113358. https://doi.org/10.1016/j.postharvbio.2024.113358

Avoco.co.nz. (2022). Maturity. Retrieved from https://www.avoco.co.nz/wp-content/uploads/2022/11/Maturity-2022-10-11-AVOCO-Orchard-Management-Guide-19.pdf

Bill, M., Sivakumar, D., Thompson, A.K., & Korsten, L. (2014): Avocado fruit quality

management during the postharvest supply chain. Food Reviews International, DOI: 10.1080/87559129.2014.907304

Goisser, S., Mempel, H., and Bitsch, V. (2020). Food-Scanners as a Radical Innovation in German Fresh Produce Supply Chains. Int. J. Food System Dynamics 11 (2), 101-116. DOI: http://dx.doi.org/10.18461/ijfsd.v11i2.43

Goisser, S., Wittmann, S., & Mempel, H. (2021). Food-scanner applications in the fruit and vegetable sector. Agricultural engineering. Eu, 76(1). https://doi.org/10.15150/lt.2021.3264

New Zealand Avocado. (2025). Maturity testing requirements. Retrieved from https://industry.nzavocado.co.nz/maturity-clearance-testing/

Olarewaju, O. O., Bertling, I., & Magwaza, L. S. (2016). Non-destructive evaluation of avocado fruit maturity using near-infrared spectroscopy and PLS regression models. Scientia Horticulturae, 199, 229-236. https://doi.org/10.1016/j.scienta.2015.12.047

Onwude, D. I., Chen, G., Kabutey, A., Khaled, A. Y., & Sturm, B. (2020). Recent Advances in Reducing Food Losses in the Supply Chain of Fresh Agricultural Produce. Processes, 8(11), 1431. https://doi.org/10.3390/pr8111431

Related Products

Most Popular Articles

- Spectrophotometry in 2023

- The Importance of Food Quality Testing

- NIR Applications in Agriculture – Everything…

- The 5 Most Important Parameters in Produce Quality Control

- Melon Fruit: Quality, Production & Physiology

- Fruit Respiration Impact on Fruit Quality

- Guide to Fresh Fruit Quality Control

- Liquid Spectrophotometry & Food Industry Applications

- Ethylene (C2H4) – Ripening, Crops & Agriculture

- Active Packaging: What it is and why it’s important